- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

HAN'S LASER

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAN'S LASER

-

Weight (KG):

-

4000 KG

-

Product name:

-

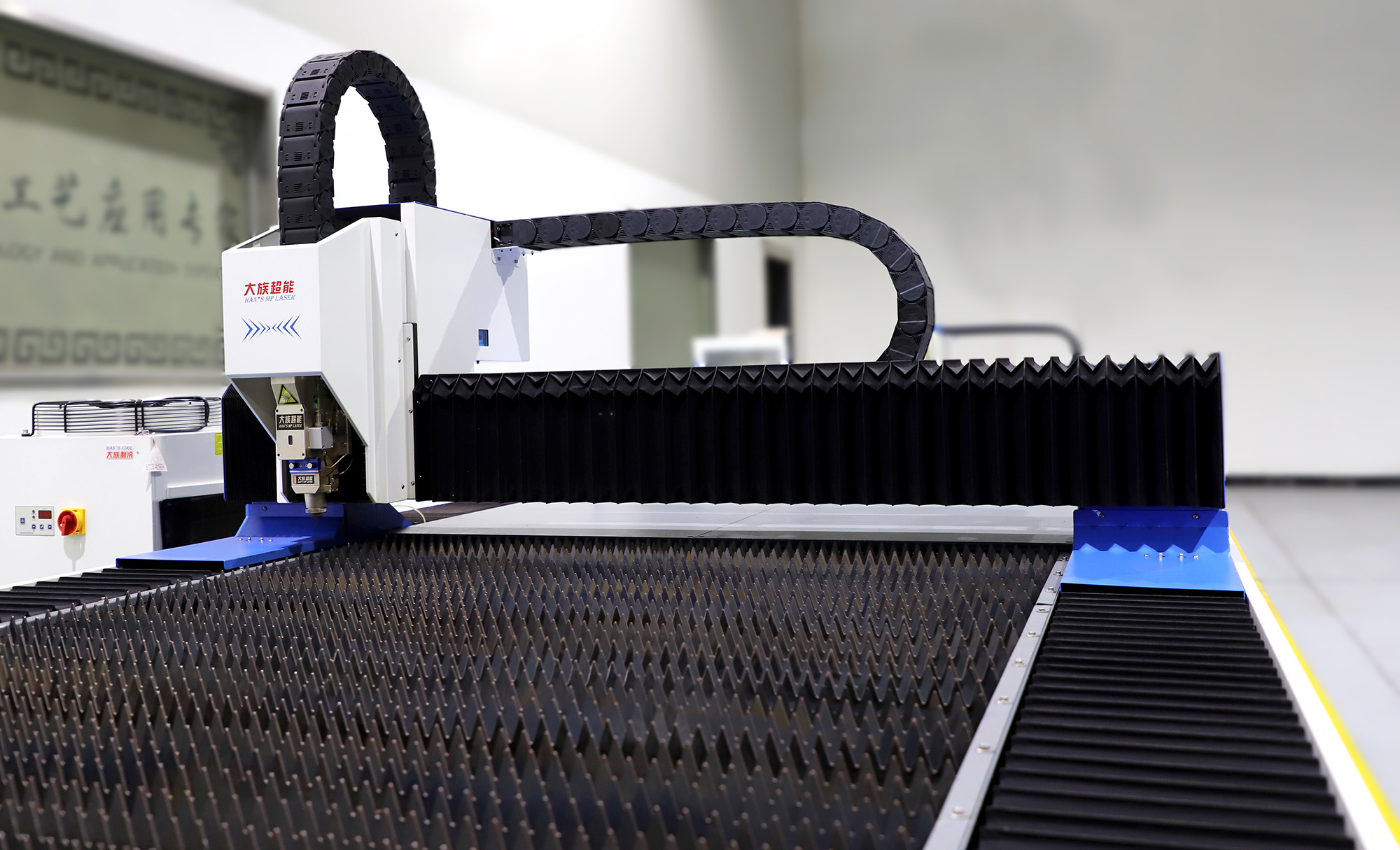

Fiber Laser Metal Cutting Machine

-

X/Y axis location accuracy:

-

±0.05mm/m

-

X/Y axis repeat location accuracy:

-

0.03mm

-

Max location speed:

-

120m/min

-

Max acceleration:

-

1.2g

-

Max load of worktable:

-

800kg

-

Machine tool weight:

-

4T

-

Dimension (L x W x H):

-

5000mmx2600mmx2000mm

-

Cooling system:

-

Water Chilller

-

After-sales Service Provided:

-

Engineers Service Overseas

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

HAN'S LASER

-

Cutting Thickness:

-

1-40mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAN'S LASER

-

Weight (KG):

-

4000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

X/Y axis location accuracy:

-

±0.05mm/m

-

X/Y axis repeat location accuracy:

-

0.03mm

-

Max location speed:

-

120m/min

-

Max acceleration:

-

1.2g

-

Max load of worktable:

-

800kg

-

Machine tool weight:

-

4T

-

Dimension (L x W x H):

-

5000mmx2600mmx2000mm

-

Cooling system:

-

Water Chilller

-

After-sales Service Provided:

-

Engineers Service Overseas

Product Description

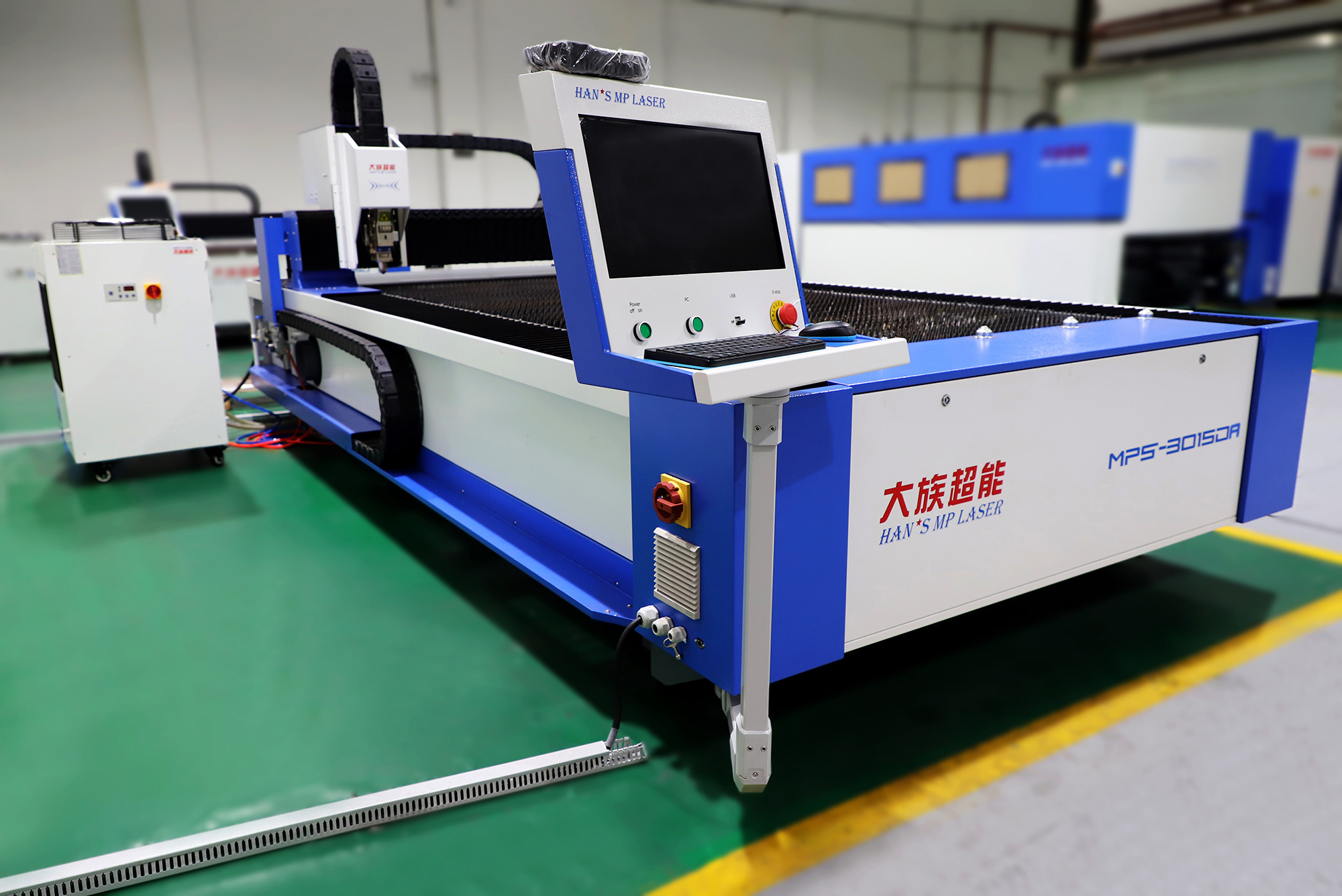

MPS-DA series laser cutting machine utilizes gear rack transmission structure, effectively ensure the running speed and accuracy, which can be widely used in general sheet metal cutting. MPS-4020DA/MPS-6020DA is main for wide and long metal plate laser processing customer demand.

MPS-DA series is an open structure fiber laser cutting machine with superior performance, stability and high cost performance.

FEATURES:

1.

Contemporary design:

Open structure without cover, showing the cutting processing completely;

2.

High processing accuracy:

Equip with high torque servo motor and high precision imported reducer, high efficiency, favorable dynamic characteristics;

3.

Good dynamics & cutting ability:

High rigidity welded body with die-cast aviation aluminum gantry, improve the gantry strength and much lighter, enjoy good stability & durability;

4.

Easy operation & intelligent:

Adopt the professional digital control system, which is developed by Han’s Laser, achieving the Han’s digital control system with the features of good performance, high reliability and convenient operation.

5.

Low running cost:

Low accessing gas consumption by precision control, to ensure the low running cost, three types of auxiliary gas can be choose freely by customer

Specification

|

Model

|

MPS-3015DA

|

|

Processing Area

|

3000mm×1500mm

|

|

X、Y axis location accuracy

|

±0.05mm/m

|

|

X、Y axis repeat location accuracy

|

±0.03mm

|

|

Max running speed

|

120m/min

|

|

Max running acceleration

|

1.2g

|

|

Max load of worktable

|

700kg

|

|

Machine tool weight

|

About 4.0T

|

|

Dimension(L*W*H)

|

5000mmx2600mmx2000mm

|

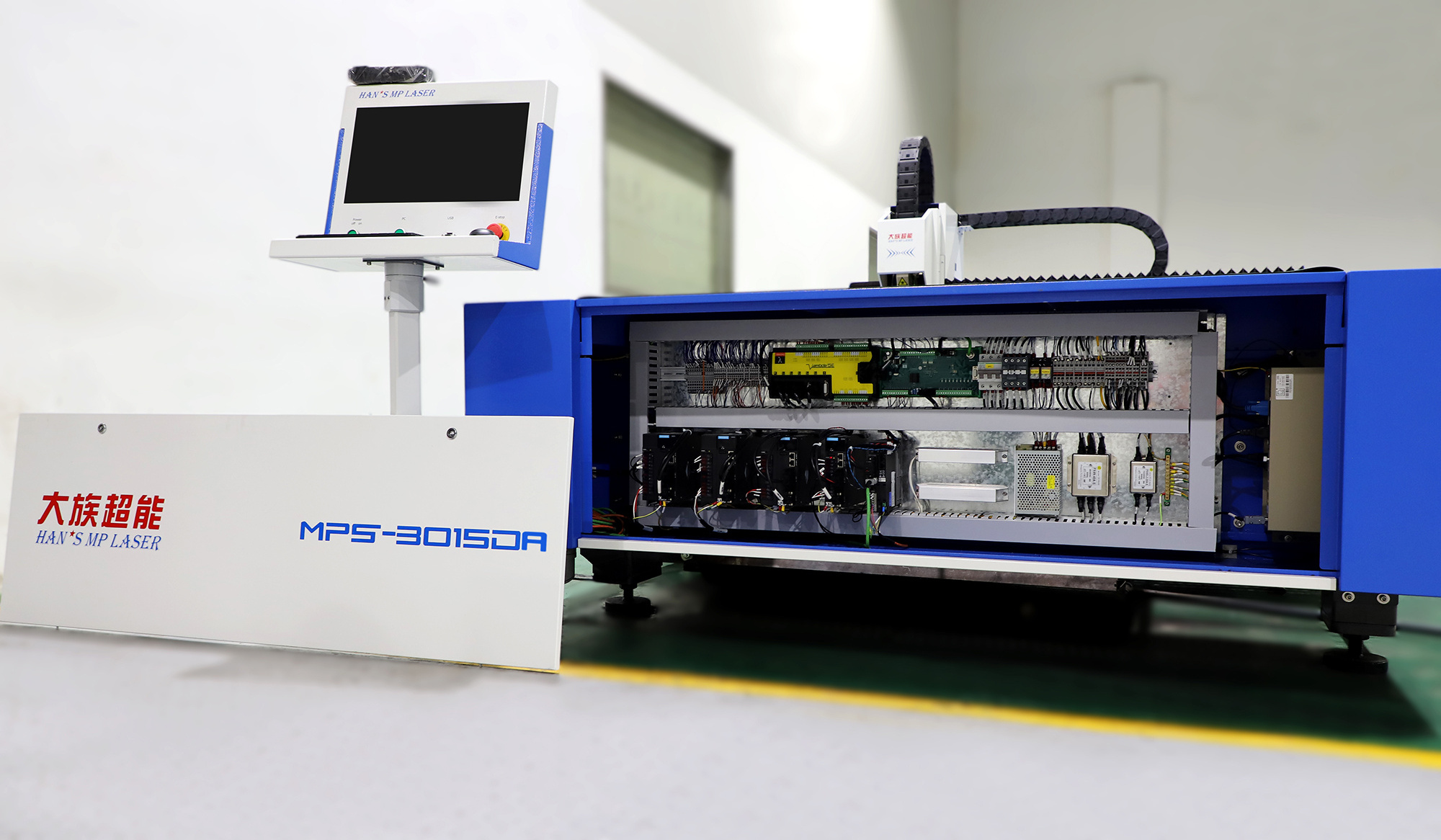

Machine Parts

1.Control system is more rational, well-developed and stable; with a central controller to control the timing of switching equipment, well protected key components of life.

2.The software interface with user-friendly design, supports AI, DXF, PLT, Gerber and other graphical data formats .

3.Control cabinet electrical key components are from Taiwan , Germany , and Japan.

HAN'S FIBER LASER SOURCE ADVANTAGES:

1.Unique combination of innovative optical fibers and advanced laser technologies guarantee long-term stability.

2.Industrial-grade quality – high reliability & durability in harsh manufacturing environments.

3.Outstanding back-reflection protection – safe processing of highly reflective materials.

4.

43% photoelectric conversion efficiency, to reduce power consumption

.

5.Remote diagnostic software for fast support.

CUTTING HEAD

ADVANTAGES

:

1.Han's IR&D laser head, focal length up to ±5mm

3.Focal two-point centering adjustment

3.Focal two-point centering adjustment

5.Permanent secondary protective window

2.Proven sealed dust proof design

4.Servo-motor driven head, fast and efficiency

6.Compatible with main brand QBH connector

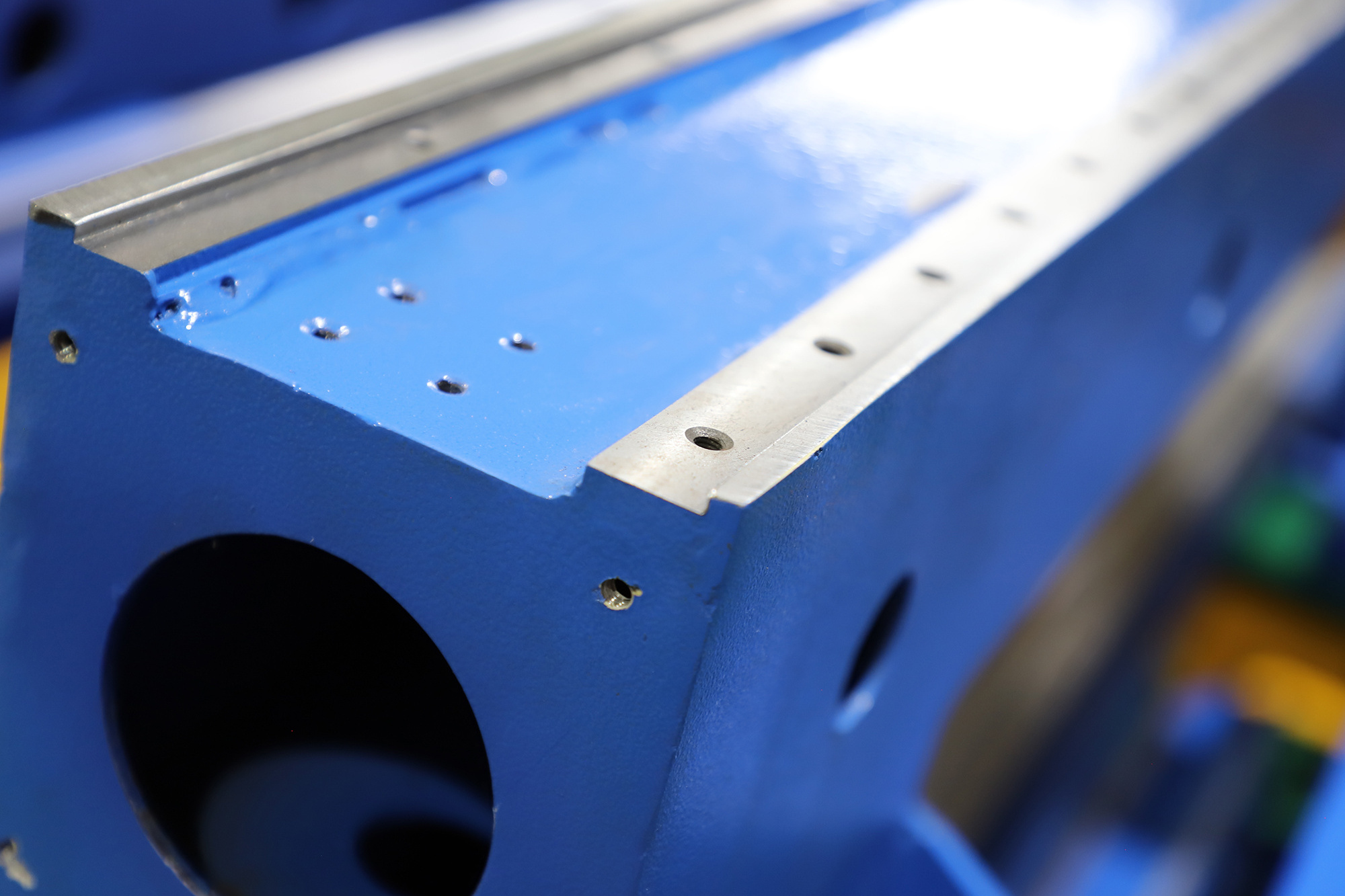

ADVANTAGES OF HONEYCOMB BEAM:

ALL LINES ESTABLISHED WITH A

HIGH-END

MACHINING CENTER

Increasing Efficiency on the Production Floor

·RMB

0.4B

Investment

·

230 sets

high-precision machining centers

·Machined parts of machine

up to 75%

·Annual output of high-end reach up to

25,000 pieces

·A total of

2.48 million parts

were manufactured.

If you have any questions, pls feel free to

contact us

.

Sample Show

|

1000W/1500W/2000W/3000W Fiber Laser Source Cutting speed M/min

|

|

|

|

|

|

|

||||||

|

Material

|

Thickness mm

|

1000w

|

1500w

|

2000w

|

3000w

|

Gas

|

||||||

|

Stainless steel

|

1

|

16.0-20.0

|

24.0-30.0

|

27.0‐35.0

|

30.0‐40.0

|

N2

|

||||||

|

Stainless steel

|

3

|

2.1-2.8

|

2.7-4.0

|

4.0‐5.5

|

7.0‐9.0

|

N2

|

||||||

|

Stainless steel

|

6

|

/

|

0.6-1.0

|

1.0‐1.5

|

1.5‐2.1

|

N2

|

||||||

|

Stainless steel

|

8

|

/

|

/

|

0.4‐0.6

|

0.8‐1.2

|

N2

|

||||||

|

Stainless steel

|

10

|

/

|

/

|

/

|

0.5‐0.7

|

N2

|

||||||

|

Carbon steel

|

1

|

9.0-15.0

|

9.0-15.0

|

9.0‐15.0

|

9.0‐15.0

|

O2

|

||||||

|

Carbon steel

|

6

|

1.2-1.6

|

1.6-2.0

|

1.8‐2.4

|

2.2‐3.0

|

O2

|

||||||

|

Carbon steel

|

16

|

/

|

/

|

0.5‐0.7

|

0.6‐0.8

|

O2

|

||||||

|

Carbon steel

|

20

|

/

|

/

|

/

|

0.4‐0.6

|

O2

|

||||||

|

Aluminum

|

1

|

8.0-10.0

|

12.0-20.0

|

20.0‐28.0

|

26.0‐32.0

|

N2

|

||||||

|

Aluminum

|

5

|

/

|

/

|

0.9-1.5

|

2.0-2.5

|

N2

|

||||||

|

Aluminum

|

6

|

/

|

/

|

/

|

1.0-1.6

|

N2

|

||||||

|

Brass

|

1

|

8.0-10.0

|

12.0-20.0

|

20.0‐26.0

|

24.0‐30.0

|

N2

|

||||||

|

Brass

|

4

|

/

|

0.8-1.2

|

1.2‐2.0

|

2.5‐3.0

|

N2

|

||||||

|

Brass

|

5

|

/

|

/

|

0.6‐1.0

|

1.8‐2.2

|

N2

|

||||||

APPLICATION INDUSTRIES:

Kitchenware industry

,

Fitness equipment application,

Agricultural machinery,

Elevator manufacturing,

Elevator manufacturing,

Furniture industry,

Automobile manufacturing,

Medical apparatus and instruments, Bicycle

manufacturing,

School tools,

etc.

Hot Searches