Controller : ESTUN E21s From China

●HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient

programming

●Backgauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device.

●Cut Stroke: Built-shearing time relay, simple operation, cost savings

●Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

●Blade gap: encoder feedback, time display blade gap size, simple operation

●Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing

maintenance costs

●All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure

product stability and service life.

●CE certified to meet the needs of overseas markets.

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

0 - 750 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BAMBOO

-

Power (kW):

-

15 kW

-

Weight (KG):

-

8700 KG

-

Place of Origin:

-

Anhui, China

-

Dimension(L*W*H):

-

3215*1970*2455

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

16 mm

-

Shearing Angle:

-

0.5°~2°30'

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

0 - 750 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BAMBOO

-

Power (kW):

-

15 kW

-

Weight (KG):

-

8700 KG

-

Place of Origin:

-

Anhui, China

-

Dimension(L*W*H):

-

3215*1970*2455

-

After-sales Service Provided:

-

Free spare parts

Features: 1.The machine adopts full steel weking structure,heating to eliminate stress,with high strength and good rigidity. 2. The German large floor boring and milling machine is used to make recision machining with one time processing method to ensure the machining precision. 3.Advanced integrated hydraulic system with and excellent reliabitity quality. 4.Rapidly,accurately and conveniently adjusting the blade clearance by motor 5.The adjustable rake angle can minimize plate deformation. 6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed. 7.Shearing in sections,shadow-line cutting. 8.Counter for the motorized back gauge. 9.Back support device (optional). Hydraulic Guillotine Shearing Machine, Steel Plate Cutting Machine Cutting length from 2000mm to 13000mm Cutting thickness from 6mm to 60mm Hydraulic Guillotine Shearing Machine, Steel Plate Cutting Machine Precision

|

Standard Configuration

|

|

|

||

|

1.

|

Controller

|

Estun E21S Controller

|

||

|

2.

|

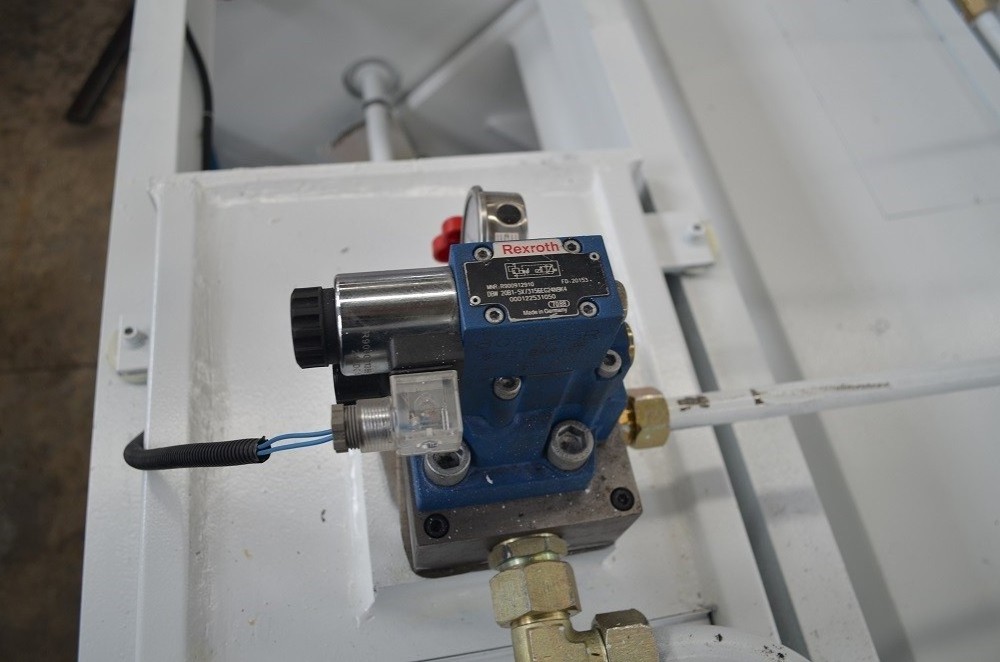

Hydraulic System

|

Bosch Rexroth From Germany

|

||

|

Hydraulic system:

--Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from Bosch -Rexroth,Germany. --All seals in cylinder is PARKER from USA,the most famous brand,good quality and high performance --Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly. --The hydraulic system is made in compliance with current regulations (Directive 98/37 EC). |

|

|

||

|

3.

|

Main Motor

|

Siemens From Germany

|

||

|

4.

|

Main Electrics

|

SCHNEIDER from France

|

||

|

Electrical system and the safety interlock:

--Electrical Cabinet under the standard of IP65, Electrical under international CE Standard, safe and reliable, strong anti interference capability --Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate --Front Side Covers with safety switches, Back light safety guards (Category-4),Foot pedal conforming to CE regulation. |

|

|

||

|

5.

|

Seal Ring

|

NOK From Japan

|

||

|

6.

|

Pipe Connector

|

EMB From Germany

|

||

|

7.

|

Ball Srew

|

Hiwin From Taiwan

|

||

|

8.

|

Limit Switch

|

SCHNEIDER from France

|

||

|

9.

|

Pump

|

Sunny From USA

|

||

|

10.

|

Foot Switch

|

Karcon From South Korea

|

||

Hydraulic System --BOSCH Rexroth from Germany

Sunny Pump

American world famous brand for hydraulic pump. It performs well and provides great power for the whole system.Using Sunny pump ensures the pump service life and lower working noise.

Electric from France Schneider

Main Motor Siemens From Germany

German famous brand motor improves the service life of the machine and keeps the machine working in a lower noise environment.

Built-in Spring Pressure Cylinder

Front Positioning Verticality Regulator

Front positioning device, setting verticality and positioning device on the left-most front support, guranteeing the cutting precision ,easy operation, pratical and efficient.

Workbench Rolling Steel Ball

Rolling steel ball of workbench can reduce friction, protect the workpiece surface.

|

Model

|

Mild Steel

(450Mpa) |

Cutting Length(mm)

|

Depth Of Throat(mm)

|

Back Gauge Range(mm)

|

Rake Angle Adjustment

|

Strokes Per Minute

|

Main Motor

|

L×W×H(mm)

|

Weight(t)

|

|

4×2000

|

4

|

2000

|

80

|

600

|

0.5°~2°

|

14

|

5.5

|

2600×1680×1750

|

3.8

|

|

4×2500

|

4

|

2500

|

80

|

600

|

0.5°~2°

|

14

|

5.5

|

3100×1750×1765

|

4.5

|

|

6×2500

|

6

|

2500

|

80

|

750

|

0.5°~1°30′

|

14

|

7.5

|

3100×1725×1900

|

5.3

|

|

6×3200

|

6

|

3200

|

80

|

750

|

0.5°~1°30′

|

12

|

7.5

|

3935×1840×1995

|

6.5

|

|

6×4000

|

6

|

4000

|

80

|

750

|

0.5°~1°30′

|

10

|

7.5

|

4650×1840×2100

|

8.5

|

|

6×5000

|

6

|

5000

|

80

|

750

|

0.5°~1°30′

|

8

|

7.5

|

5650×2185×2380

|

10.5

|

|

6×6000

|

6

|

6000

|

80

|

750

|

0.5°~1°30′

|

8

|

7.5

|

6650×2260×2380

|

15.2

|

|

8×2500

|

8

|

6000

|

80

|

750

|

0.5°~1°30′

|

14

|

7.5

|

3135×1840×2075

|

6

|

|

8×3200

|

8

|

3200

|

80

|

750

|

0.5°~1°30′

|

12

|

7.5

|

3850×1990×2050

|

6.8

|

|

8×4000

|

8

|

4000

|

80

|

750

|

0.5°~1°30′

|

10

|

7.5

|

4650×2030×2075

|

9

|

|

8×5000

|

8

|

5000

|

80

|

750

|

0.5°~2°

|

7

|

15

|

5650×2050×2400

|

12.5

|

|

8×6000

|

8

|

6000

|

100

|

750

|

0.5°~2°

|

7

|

15

|

6805×2115×2715

|

19.8

|

|

10×2500

|

10

|

2500

|

100

|

750

|

0.5°~2°30′

|

10

|

15

|

3195×1915×2205

|

8

|

|

10×3200

|

10

|

3200

|

100

|

750

|

0.5°~2°30′

|

8

|

15

|

3895×1900×2235

|

8.8

|

|

10×4000

|

10

|

4000

|

100

|

750

|

0.5°~2°30′

|

6

|

15

|

4695×1970×2270

|

9.15

|

|

10×5000

|

10

|

5000

|

100

|

750

|

0.5°~2°30′

|

5

|

15

|

5700×2115×2715

|

16

|

|

10×6000

|

10

|

6000

|

100

|

750

|

0.5°~2°30′

|

5

|

15

|

6905×2115×2800

|

22

|

|

12×2500

|

12

|

2500

|

100

|

750

|

0.5°~2°30′

|

10

|

15

|

3195×2000×2210

|

8.3

|

|

12×3200

|

12

|

3200

|

100

|

750

|

0.5°~2°30′

|

8

|

15

|

3895×2050×2240

|

9.2

|

|

12×4000

|

12

|

4000

|

100

|

750

|

0.5°~2°30′

|

5

|

15

|

4710×2110×2450

|

13

|

|

12×5000

|

12

|

5000

|

100

|

750

|

0.5°~2°30′

|

5

|

30

|

5750×2115×2800

|

20

|

|

12×6000

|

12

|

6000

|

100

|

750

|

0.5°~2°30′

|

5

|

30

|

7150×2300×3100

|

29

|

|

16×2500

|

16

|

2500

|

100

|

750

|

0.5°~2°30′

|

8

|

15

|

3215×1970×2340

|

8.7

|

|

16×3200

|

16

|

3200

|

100

|

750

|

0.5°~2°30′

|

7

|

15

|

3915×1970×2455

|

11

|

|

16×4000

|

16

|

4000

|

100

|

750

|

0.5°~2°30′

|

6

|

15

|

4715×2010×2590

|

15

|

|

16×5000

|

16

|

5000

|

100

|

750

|

0.5°~3°

|

5

|

30

|

6000×2300×3000

|

23

|

|

16×6000

|

16

|

6000

|

80

|

750

|

0.5°~3°

|

5

|

37

|

7250×2400×3100

|

36

|

|

20×2500

|

20

|

2500

|

100

|

750

|

0.5°~3°

|

6

|

22

|

3235×2020×2465

|

10.5

|

|

20×3200

|

20

|

3200

|

120

|

750

|

0.5°~3°

|

5

|

30

|

4150×2065×2755

|

18

|

|

20×4000

|

20

|

4000

|

120

|

750

|

0.5°~3°

|

4

|

30

|

4955×2125×2885

|

21

|

|

20×5000

|

20

|

5000

|

120

|

750

|

0.5°~3°

|

4

|

37

|

6000×2300×3050

|

29

|

|

25×2500

|

25

|

2500

|

120

|

750

|

0.5°~3.5°

|

5

|

37

|

3465×2130×2710

|

15

|

|

25×3200

|

25

|

3200

|

120

|

750

|

0.5°~3.5°

|

5

|

37

|

4120×2200×3000

|

21

|

|

25×4000

|

25

|

4000

|

120

|

750

|

0.5°~3.5°

|

4

|

37

|

4950×2200×3150

|

26

|

|

30×2500

|

30

|

2500

|

120

|

750

|

0.5°~3.5°

|

4

|

37

|

3465×2170×2770

|

16

|

|

30×3200

|

30

|

3200

|

120

|

750

|

1°~3.5°

|

3

|

45

|

4200×2300×3200

|

23

|

|

40×2500

|

40

|

2500

|

180

|

750

|

1°~4°

|

4

|

45

|

3770×2550×3400

|

29

|

|

40×3200

|

40

|

3200

|

180

|

750

|

1°~4°

|

4

|

55

|

3770×2550×3400

|

29

|