- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

INNOVACERA

-

Weight:

-

0.1 KG

-

Working Temperature Range:

-

-50 - 800 ℃

-

Core Components:

-

Ceramic Heater

-

Color:

-

White

-

Density:

-

3.7g/cm3

-

Alumina Content:

-

95%

-

Water Absorption:

-

0%

-

Thermal Conductivity:

-

25 W/(m.k)

-

Flexural Strength:

-

300 Mpa

-

Compressive Strength:

-

2000 Mpa

-

Max. Use Temperature:

-

1600℃

-

Vickers Hardness:

-

11.5 Gpa

-

Dielectric Strength:

-

>12 KV/mm

Quick Details

-

Type:

-

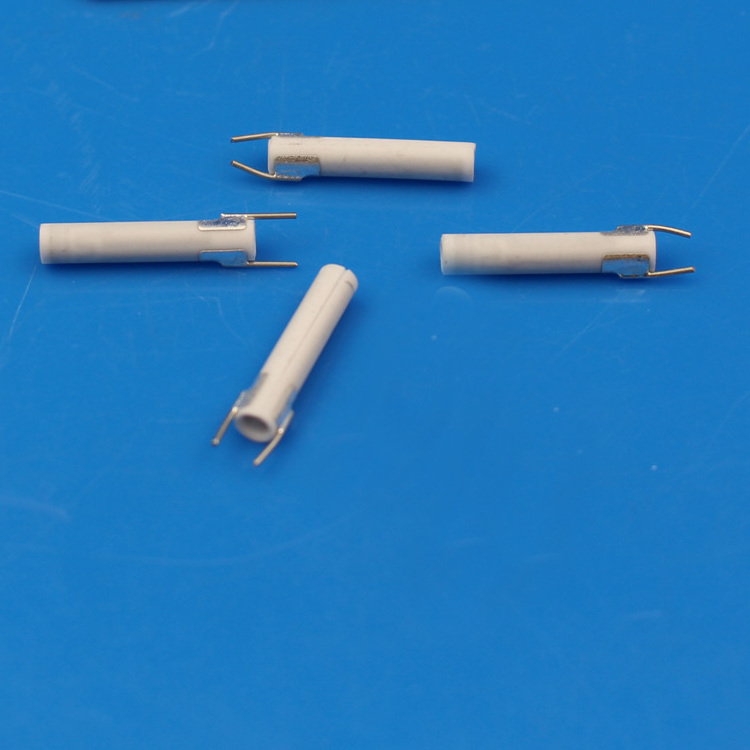

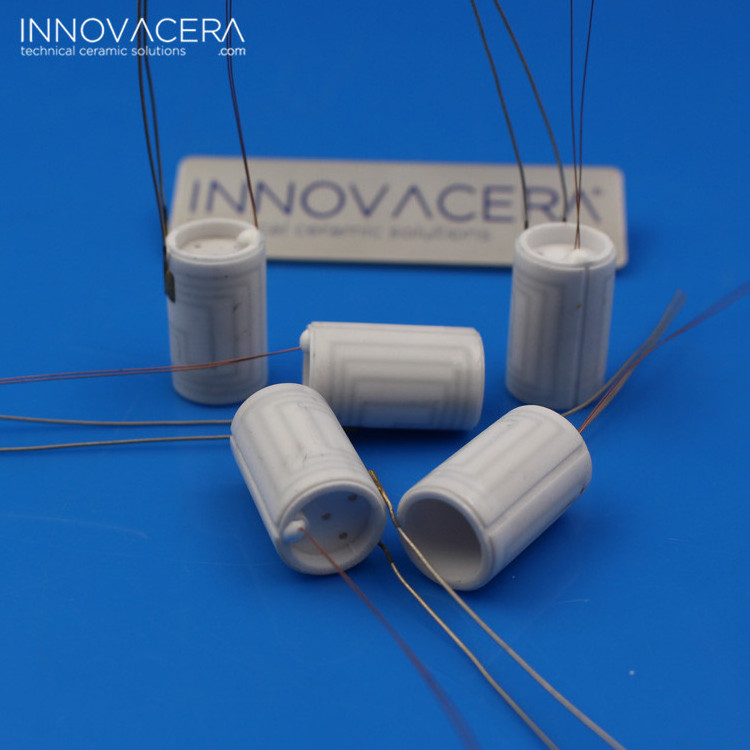

Ceramic Heater

-

Power Source:

-

Electric

-

Voltage:

-

3.7-240v

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

INNOVACERA

-

Weight:

-

0.1 KG

-

Working Temperature Range:

-

-50 - 800 ℃

-

Core Components:

-

Ceramic Heater

-

Color:

-

White

-

Density:

-

3.7g/cm3

-

Alumina Content:

-

95%

-

Water Absorption:

-

0%

-

Thermal Conductivity:

-

25 W/(m.k)

-

Flexural Strength:

-

300 Mpa

-

Compressive Strength:

-

2000 Mpa

-

Max. Use Temperature:

-

1600℃

-

Vickers Hardness:

-

11.5 Gpa

-

Dielectric Strength:

-

>12 KV/mm

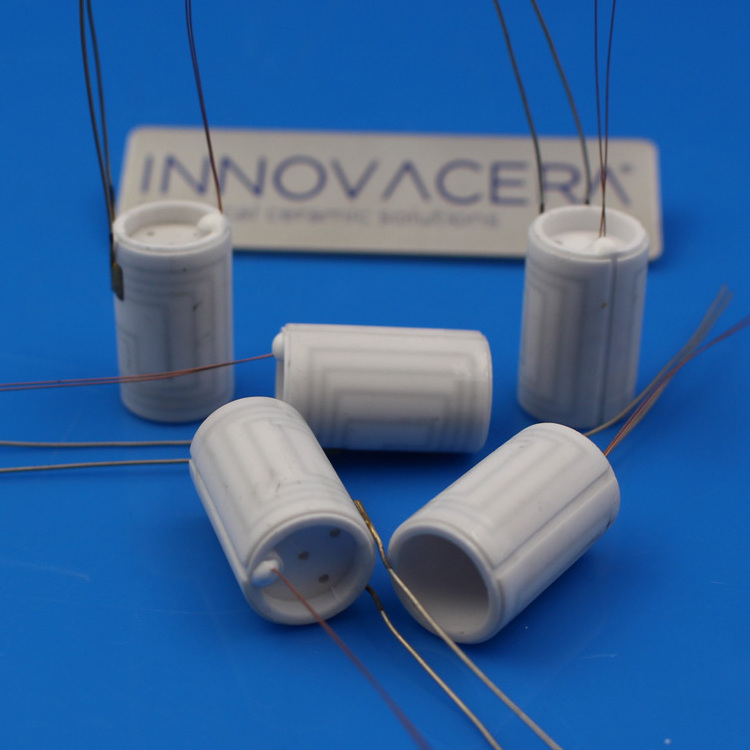

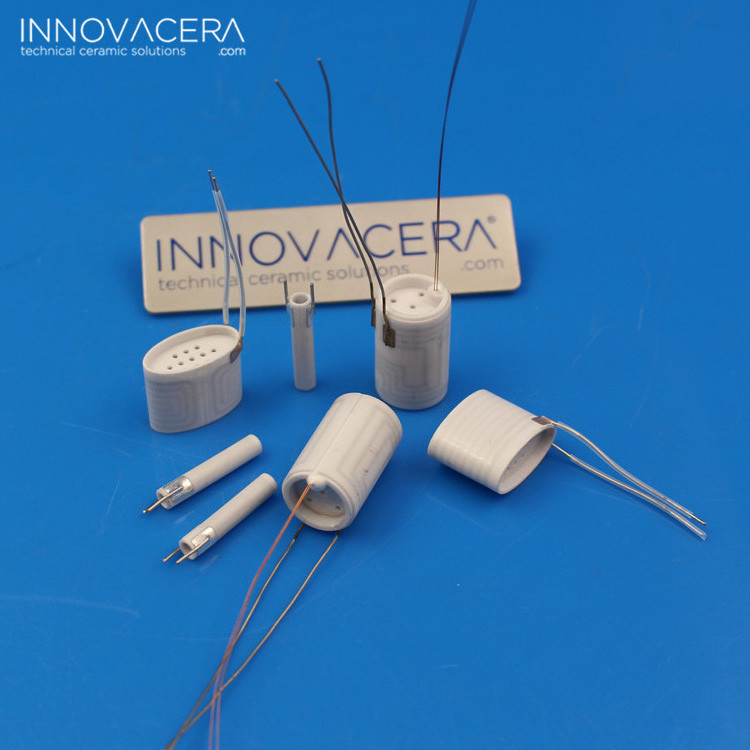

Advantages of INNOVACERA Ceramic Heater

Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before. Currently, applications include use as innovative types of heaters in the automotive and semiconductor industries.

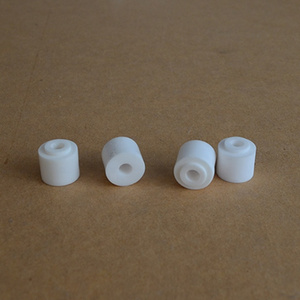

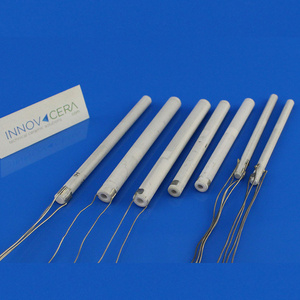

Compact, Lightweight and Energy Efficient

Small size but high watt, and excellent thermal efficiency. Multiple heating elements can be layered into a single unit.

Superior Thermal Properties

Rapid heating-up, available with custom-designed heat distribution patterns. Strong insulation properties permit direct contact with a variety of materials, including water, kerosene and metals.

High Reliability

Superior voltage resistance and electrical resistance.The oxidation-resistant material ensures a long service life.

|

Thermal Properties for Alumina Heater

|

|

|

||

|

Item

|

Unit

|

Value

|

||

|

Vickers Hardness

|

Gpa

|

11.5

|

||

|

Flexural Strength

|

Mpa

|

300

|

||

|

Compressive Strength

|

Mpa

|

2000

|

||

|

Modulus of Elasticity

|

Gpa

|

300

|

||

|

Poisson's Ratio

|

---

|

0.22-0.23

|

||

|

Fracture Toughness

|

Mpam

1/2

|

3.5-4.0

|

||

|

Thermal Conductivity

|

W/(m·k)

|

25

|

||

|

Thermal Expansion Coefficient

|

10

-6

/℃

|

6.5-7.5

|

||

|

Thermal Shock Resistance

|

△T℃

|

200

|

||

|

Maximum Use Temperature

|

℃

|

1600

|

||

|

Dielectric Strength

|

KV/mm

|

>12

|

||

|

Dielectric Constant

|

εr

|

9-10

|

||

|

Dielectric Loss Angle (1MHz)

|

---

|

0.0002

|

||

|

Volume Resistivity

|

Ω.m

|

>10

15

|

||

|

Specific Heat

|

J/(kg·k)

|

0.78x10

3

|

||

About INNOVACERA

IINNOVACERA engages in R&D, manufacturing and selling the products of advanced ceramic materials, including Alumina, Zirconia, Boron Nitride, Silicon Nitride, Machinable Glass Ceramic and other advanced materials. Through different manufacturing processes, we supply metallized ceramic components, alumina heater, ceramic pump components and other ceramic components as request.

Our products are mainly used in Aerospace, Research, Food Processing, Fluid Handling, Scientific, Automotive,Thermal Processing, Electronic and Electrical, Process Control, Textile, Pulp and Paper, Mechanical, Glass Processing, Mineral Processing and other Industrials.

|

Packaging

|

|

|

|

Size

|

L *W * D

|

|

|

Weight

|

KGS

|

|

|

Packaging Details

|

The normal package is Corrugated box with foam .If container is over 15KGS,we will use Wood box for outer packing or pack it according to customers special request.

|

|