- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

415

-

Dimension(L*W*H):

-

6 ft x 6 ft x 10 ft

-

Weight (T):

-

12 T

-

Power (kW):

-

20

-

Capacity:

-

1 ton/ Batch

-

Fuel:

-

Natural Gas PNG

-

Fuel Consumption:

-

70 - 75 m3 / ton

-

Burners:

-

Fully Automatic

-

Tilting:

-

Hydraulic Tilting Operation

-

Frequency:

-

50Hz/60Hz

-

Duty cycle:

-

Continuous Work

-

Advantage:

-

Reduce Production Time

-

Certification:

-

ISO 9001-2008 TUV

Quick Details

-

Place of Origin:

-

Haryana, India

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

INDOTHERM EQUIPMENT CORPORATION

-

Voltage:

-

415

-

Dimension(L*W*H):

-

6 ft x 6 ft x 10 ft

-

Weight (T):

-

12 T

-

Power (kW):

-

20

-

Capacity:

-

1 ton/ Batch

-

Fuel:

-

Natural Gas PNG

-

Fuel Consumption:

-

70 - 75 m3 / ton

-

Burners:

-

Fully Automatic

-

Tilting:

-

Hydraulic Tilting Operation

-

Frequency:

-

50Hz/60Hz

-

Duty cycle:

-

Continuous Work

-

Advantage:

-

Reduce Production Time

-

Certification:

-

ISO 9001-2008 TUV

We are primary manufacturers of top notch quality aluminum melting furnaces which are manufactured to dish up a variety of industrial purposes as well ability to melt 30 to 5000 kg/hr Aluminium. Melting takes place by direct firing of the burner in the furnace hall along efficient and fast heating.

Aluminium Melting Reverberatory Furnaces which are suitable for scrap reuse / Die-casting units where scrap will be melted into Casting or Ingots. Ready metal can be route for alloy correction and then to be shifted to the final product. These furnaces are continuous Melting Furnaces which can run smoothly for hours and needs very less labor to operate.

When choosing aluminium Melting Furnace please keeps in mind your product which you want to produce i.e. Aluminium Ingots or particularly you want to do casting.

Applications:

Metal casting

Foundries

Alloy Melting

Refining of various materials etc.

Melting as well as Holding can be done in the same furnace.

After taking the production the furnace can be easily cleaned and less time to go for the next heat.

Veto shade corners in refractory which allow easy and thorough clean-up .

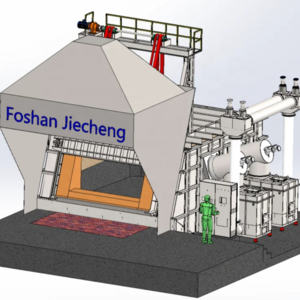

Hydraulic Tilting cylinders make the furnace smooth when metal taping is done

|

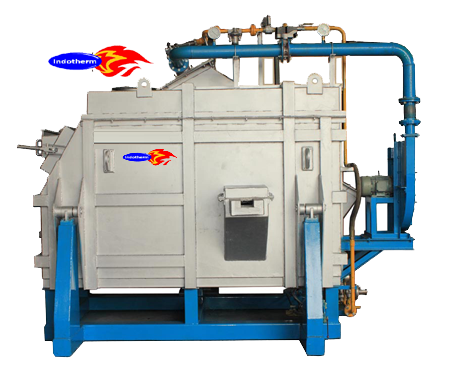

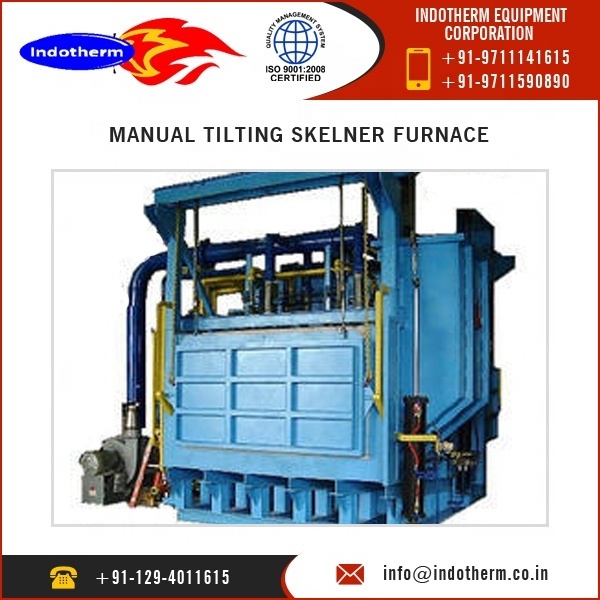

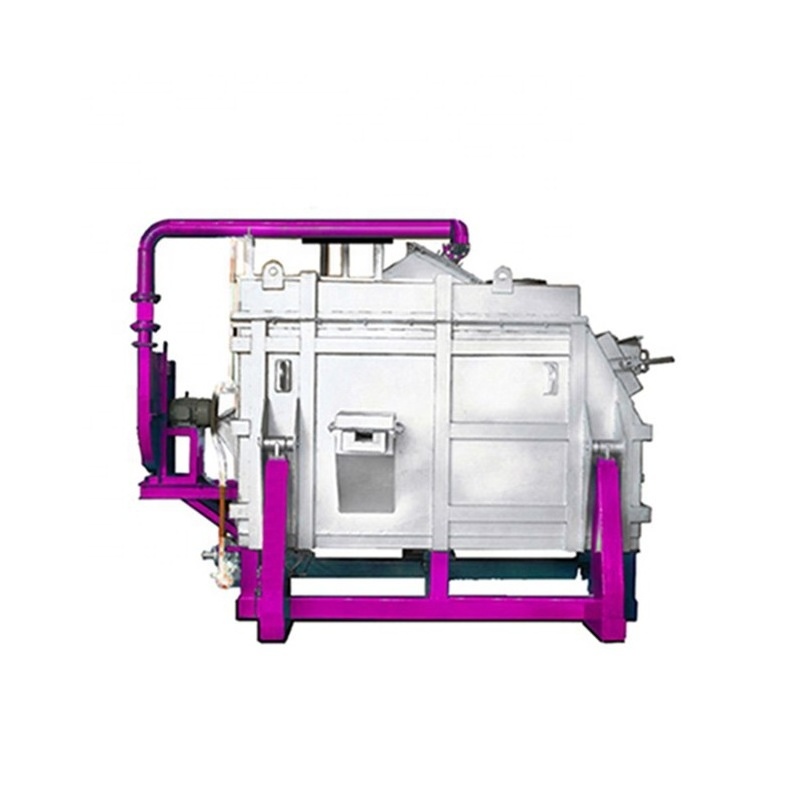

Aluminium Melting Skelner Furnace |

|

|

Fuel Consumption |

1000KWH/ton at 7200C Tap out temperature |

|

Metal loss |

Approx 6% - 8 % |

|

Capacity |

1000kg/Batch |

|

Loading |

Manual |

|

Metal tapping |

By Plug system or Hydraulically Tilting mechanism. |

|

Fuel |

LDO/FO/HSD/LPG/Propane |

Since its establishment in 1991, Indotherm Equipment Corporation has focused on manufacturing, exporting, and supplying high-standard furnaces and belt conveyors. As an ISO 9001:2008 certified firm, our product range includes Crucible Furnace, Rotary Furnace, Hydraulic Tilting Furnaces, Reverberatory Furnaces, and Tilting Reverberatory Furnaces. Our primary objective is to provide products that prioritize safety and environmental friendliness, with a notable emphasis on energy-saving capabilities and reduced fuel consumption.

To ensure product quality, we maintain a directory of authorized vendors and conduct thorough research to select reliable suppliers. The raw materials undergo stringent quality checks by both the vendors and our own quality tests, ensuring compliance with industry standards. Our commitment to quality has garnered praise from clients, enabling us to establish a strong market position based on exceptional service and top-notch products.

Equipped with cutting-edge machinery, our packaging unit ensures secure export and delivery of products worldwide. Our dedicated team stays updated with the latest technology, enabling us to deliver high-class products. Under the guidance of Mr. C. L. Tripathi, who prioritizes customer satisfaction and environmental safety, we continuously strive to deliver superior, energy-efficient products. Indotherm Equipment Corporation is committed to providing high-quality products, advancing the aluminum industry, and maintaining customer satisfaction.

Overall, Indotherm Equipment Corporation is dedicated to delivering high-quality products, maintaining customer satisfaction, and contributing to the advancement of the aluminum industry.