- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

iPANDA

-

Dimension(L*W*H):

-

2300(L)*1200(W)*1750(H) mm

-

Weight:

-

600 KG

-

Product name:

-

nail polish filling and capping machine

-

Filling material:

-

Flowing Liquid

-

Function:

-

Filling and capping

-

Capacity:

-

2000-3000bph

-

Filling tolerance:

-

0-1%

-

bottle volume:

-

5-50ml customized

-

Machine material:

-

Stainless Steel SUS304/SUS316

-

Filling head:

-

Support Customization

-

Air pressure:

-

0.4-0.6Mpa

-

Control:

-

PLC+ Touch Screen

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Machinery Capacity:

-

4000BPH, 100BPH, Customize

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

nail polish

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

iPANDA

-

Dimension(L*W*H):

-

2300(L)*1200(W)*1750(H) mm

-

Weight:

-

600 KG

-

Product name:

-

nail polish filling and capping machine

-

Filling material:

-

Flowing Liquid

-

Function:

-

Filling and capping

-

Capacity:

-

2000-3000bph

-

Filling tolerance:

-

0-1%

-

bottle volume:

-

5-50ml customized

-

Machine material:

-

Stainless Steel SUS304/SUS316

-

Filling head:

-

Support Customization

-

Air pressure:

-

0.4-0.6Mpa

-

Control:

-

PLC+ Touch Screen

-

Marketing Type:

-

Hot Product 2022

Products Description

The nail polish bottle filling capping machine has the advantages of simple operation, accurate filling, simple equipment cleaning and maintenance. Widely used in daily chemical, oil and other industries, can be filled with nail polish, gel polish, viscous cosmetics and other liquid products. The machine is compact and reasonable design, simple and beautiful appearance, easy to adjust the filling volume.

Features:

1.

The electric and pneumatic components of the nail polish filling machine are all world famous brands, with stable performance, low failure rate and relatively long service life;

2. nail polish filling machine and material contact are made of stainless steel, disassembly simple, easy to clean, in line with food hygiene requirements;

3. filling volume and filling speed adjustment is simple, with no bottle no filling function, liquid level automatic control feeding, beautiful appearance;

4. you can quickly adjust the machine for filling different shapes and sizes of the bottle;

5. filling mouth with anti-drip device to ensure no wire drawing, no leakage;

6. It is fully compliance with GMP requirements.

2. nail polish filling machine and material contact are made of stainless steel, disassembly simple, easy to clean, in line with food hygiene requirements;

3. filling volume and filling speed adjustment is simple, with no bottle no filling function, liquid level automatic control feeding, beautiful appearance;

4. you can quickly adjust the machine for filling different shapes and sizes of the bottle;

5. filling mouth with anti-drip device to ensure no wire drawing, no leakage;

6. It is fully compliance with GMP requirements.

Product Details

Warm Tip:

1. If out of filling volume range, we could customize for you.

2. If need higher capacity, please reach us to customize the machine with more filling nozzles.

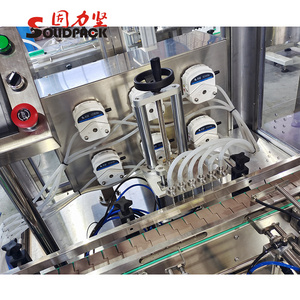

We adopt peristaltic pump, suitable for fluid, such as nail gel, eyedrop etc.

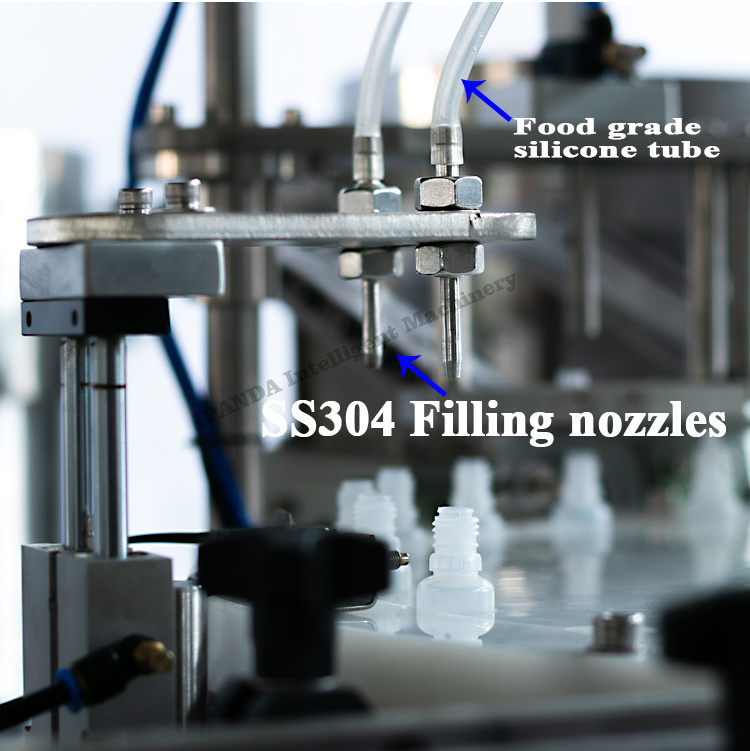

We adopt SS304 filling nozzles and Food grade silicone tube.

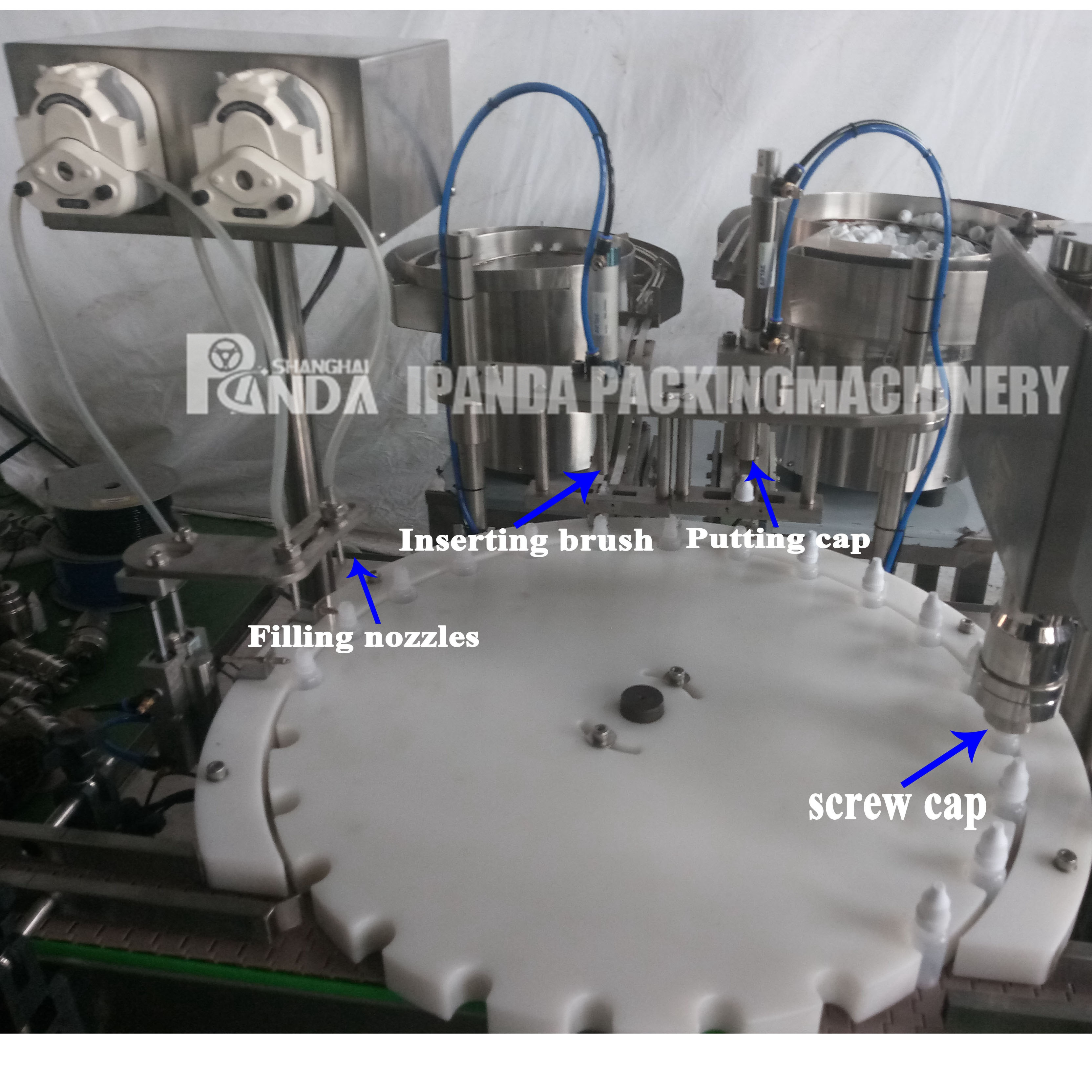

Filling accurate, stoppers and cap feeding precision

Filling accurate, stoppers and cap feeding precision

Main Technical Parameters

|

Packaging Material

|

Plastic & glass bottles

|

|

|

Filling Speed

|

2000-3000BPH

|

|

|

Bottle Volume

|

2-200ml(Different type machine)

|

|

|

Bottle Size

|

Can be customized

|

|

|

Filling Speed

|

15-80 bottles/min

|

|

|

Power

|

1.8kw,120V/220V/380V

|

|

|

Qualified Stoppering

|

≥99%

|

|

|

Qualified Cap Putting

|

≥99%

|

|

|

Qualitfied Capping

|

≥99%

|

|

|

Application

|

Super spray, eyedrop,etc.

|

|

|

|

||

Main Accessory Part:

|

Machine frame

|

SUS304 Stainless steel

|

|

|

|

Peristaltic pump

|

WATSON MARLOW Peristaltic pump (UK) / Piston pump

|

|

|

|

Main Motor

|

ABB

|

Switzerland

|

|

|

Inverter

|

Mitsubishi

|

Japan

|

|

|

Air Switch

|

Schneider

|

France

|

|

|

Contactor

|

Schneider

|

France

|

|

|

Relay

|

Omron

|

Japan

|

|

|

OFA

|

Autonics

|

Korea

|

|

|

Bearing

|

IGUS

|

Germany

|

|

|

CAM indexer

|

Shangdong

|

China

|

|

|

Turntable(optional)

|

Plastic POM

|

Japan

|

|

|

Cylinder

|

AIRTAC

|

Taiwan

|

|

|

Touch screen(optional)

|

Siemens

|

Germany

|

|

|

PLC(optional)

|

Siemens

|

Germany

|

|

|

Servo motor

|

Delta

|

Taiwan

|

|

Before order service

We will according to your requirement make details quotation for you.

We can send you some our machine running video similar to your product.

If you come to china,we can pick you up from airport or station near our city.

After order service

We will start to make machine,and take some picture by 10 days of our production process .

Our engineer can design the layout according to your requirement.

We will supply commission service if customer need.

Our engineer can design the layout according to your requirement.

We will supply commission service if customer need.

After-sales service

We will testing machine ,and take some video and picture to you if u not come to china inspect machine.

After testing machine we will packing machine ,and delievery container on time.

We can send our engineer to you country help you install and testing machine.we can training you technical staff free until they can running machine independent.

Our company will give you all machine with 1 years guaranteen.In 1years you can get all spare parts free from us.we can send you by express.

After testing machine we will packing machine ,and delievery container on time.

We can send our engineer to you country help you install and testing machine.we can training you technical staff free until they can running machine independent.

Our company will give you all machine with 1 years guaranteen.In 1years you can get all spare parts free from us.we can send you by express.

Hot Searches