- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V, 220V, 380V ,400V

-

Dimension(L*W*H):

-

1340*1320*1320mm

-

Weight (KG):

-

1100

-

Power (kW):

-

1.1

Quick Details

-

Year:

-

2023

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ctmach

-

Voltage:

-

110V, 220V, 380V ,400V

-

Dimension(L*W*H):

-

1340*1320*1320mm

-

Weight (KG):

-

1100

-

Power (kW):

-

1.1

Features

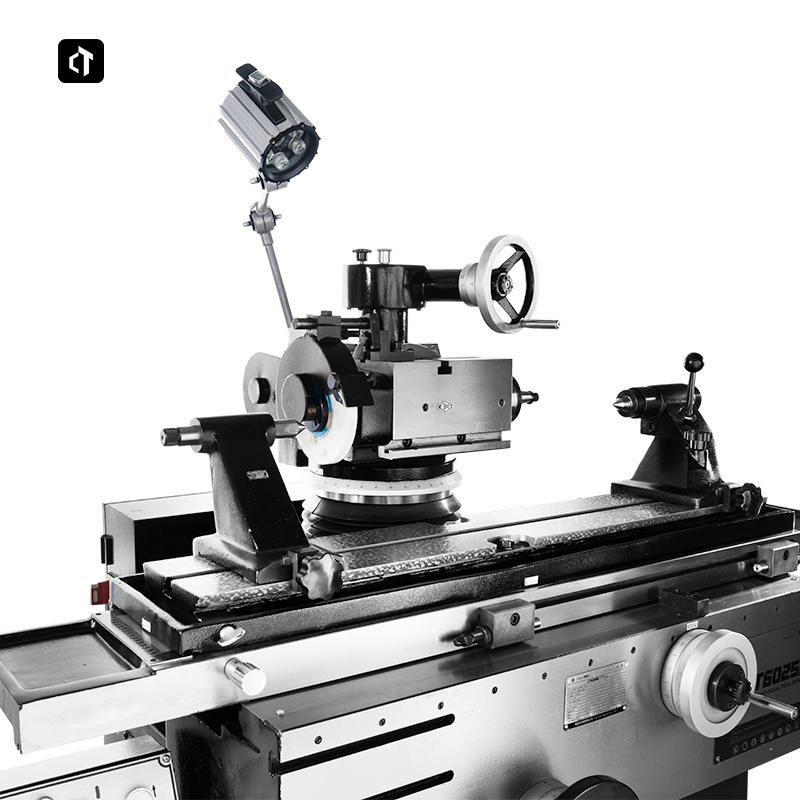

1. Both HSS cutters and Carbide cutters are available for sharpening.

2. Precision linear guideway makes the table stable and smoothly operated.

3. The motor could rotate 360º in the horizontal plane allowing easy access to the workpiece.

4. The machines base is made of cast steel construction resulting in high stability during operation.

5. The sliding table is mounted on precise linear ball rails that provide smooth and accurate movement.

6. The grinding head support is made up of double rotating bracket, which allows the head to rotate in both the horizontal and vertical plane.

7. The column structure enables it to lower and raise the grinding wheel.

8. The motorized workhead allows for small cylindrical grinding between centers or if required single ended work mounted in the chuck.

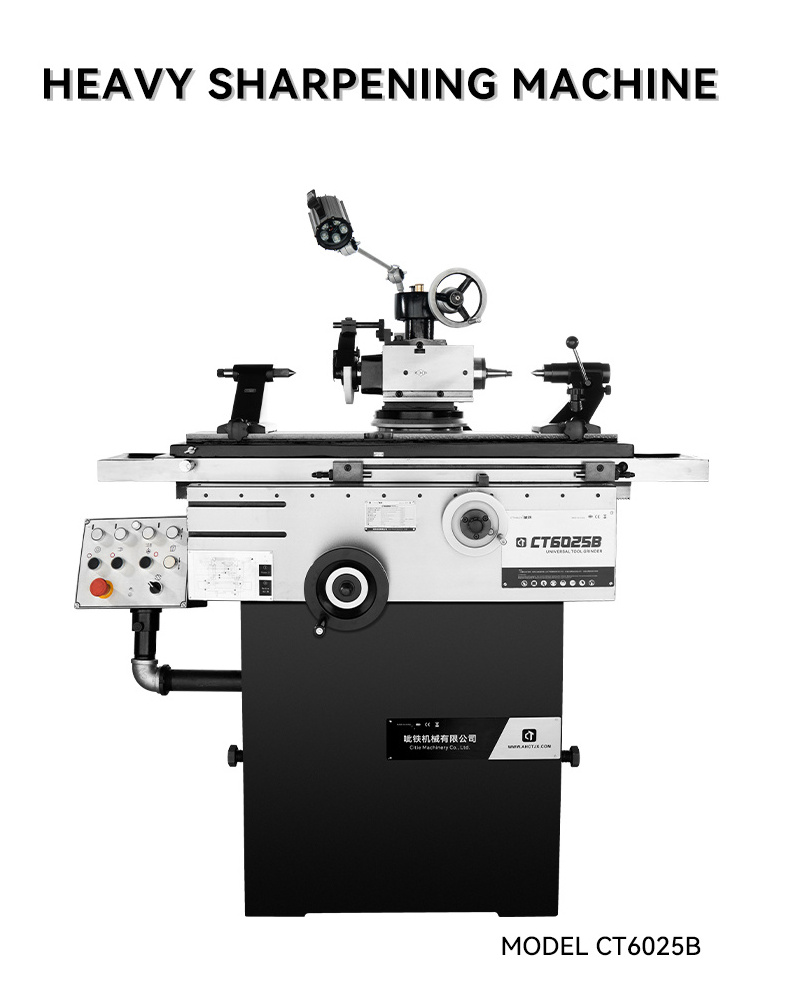

Product specifications

|

MODEL

|

CT6025B

|

|

|

Maximum rotation diameter of top upper table

|

250mm

|

|

|

The maximum length of the workpiece between the left and right tailstock tips

|

650mm

|

|

|

Distance between tool grinding stand and tailstock tip

|

545mm

|

|

|

Maximum size of the grindable surface (length × width)

|

350×100mm

|

|

|

The maximum length of the outer circle that can be ground

|

270mm

|

|

|

Maximum weight supported between tips

|

12kg

|

|

|

Workbench surface dimensions length × width

|

900×140mm

|

|

|

Maximum stroke

|

400mm

|

|

|

Maximum rotation angle

|

±45°

|

|

|

Running speed

|

Manual

|

|

|

Wheel stand

|

|

|

|

Lateral movement

|

230mm

|

|

|

Vertical movement amount

|

250mm

|

|

|

Maximum/minimum distance from grinding wheel centerline to worktable

|

298/48mm

|

|

|

Motorized lifting speed

|

280mm/min

|

|

|

Rotation angle in horizontal plane

|

360°

|

|

|

Rotation angle in vertical plane

|

±15°

|

|

|

Grinding wheel spindle speed

|

2700 4000 5500 r/min(50HZ)

|

|

|

|

3100 4600 6300 r/min(60HZ)

|

|

|

Universal chuck

|

|

|

|

Spindle speed r/min

|

170、270(50HZ) 195、310(60HZ)

|

|

|

Spindle taper

|

ISO .NO.50/M.T.NO.2-5

|

|

|

Tailstock taper

|

MT2

|

|

|

Power

|

|

|

|

Grinding wheel frame motor

|

1100W 2780r/min

|

|

|

Column lifting motor

|

90W 1400r/min

|

|

|

Hydraulic pump motor

|

370W 1400r/min

|

|

|

Universal chuck motor

|

80W 700r/min

|

|

|

Grinding wheel size (outer diameter × width × inner diameter)

|

|

|

|

Dish-shaped

|

D1 150×16×32mm

|

|

|

|

BW 125×45×32mm

|

|

|

|

BW 75×32×20mm

|

|

|

Cup-shaped

|

B1 25×63×32mm

|

|

|

Flat shape

|

P1 50×16×32mm

|

|

|

Overall dimensions (length × width × height)

|

1340×1320×1320mm

|

|

|

Net weight (including random accessories)

|

1100kg

|

|

Size/Weight

The appearance/package size of the product is measured manually, and there is a small error. It is normal, and the specific object shall prevail.

CT6025B Machine size 1340×1320×1320mm

CT6025B Machine weight 1100kg

Hydraulic forklifts or cranes are recommended for handling

Product display

Details introduce

SALES AND SERVICE NETWORK

Products are exported to more than 30 countries and regions in the world

EU CE standard, safe and reliable

ISO9001 quality system certification

COMPANY PROFILE

FAQ

Q.What are your normal lead times?

A.Usually, we have stock of the machine, for stock machine we can send it out within 5days after got the payment. And for

customized machine need 20-30days after got the payment.

Q.What is the MOQ for your production?

A.The MOQ depends on your requirements for color, logo and so on.For some normal items, we have in stock, the MOQ is 1 set.

Q.Do you have CE certification?

A.Yes, we have CE certification.

Q: How is the Quality warranty?

A: Warranty time is 13 months after BL date. And every machine before send it out, we have quality controller to test the machine.

Q. Do you have technical support?

A. Yes, we have professional techinal department, they will help solve your problem at anytime.

Q.What kind of package do you offer?

A.Normally in polywood case, to make sure all machines in good condition when shipping.

Hot Searches