- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZOZEN

-

Dimension(L*W*H):

-

Determined by boiler capacity

-

Weight:

-

Determined by boiler capacity

-

Name:

-

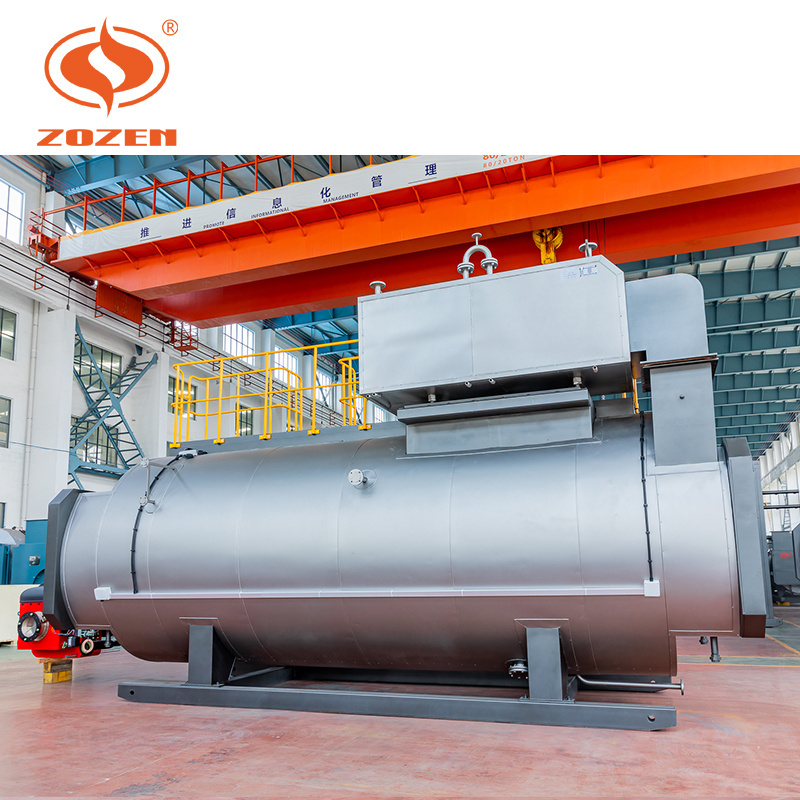

WNS oil gas steam boiler

-

Product thermal capacity:

-

3 ton

-

Working pressure:

-

1.25 Mpa

-

Available fuel:

-

Nature gas, coke oven gas, biogas, methanol, etc

-

Application field:

-

Heat suppling, chemical, food,building materials

-

Advantages:

-

Top 1 A-Class Boiler

-

Operation:

-

Automatic Control

-

Other Boilers:

-

Coal Fired Boiler Gas Fired Boiler

-

Quality:

-

100% Tested

-

Manufacturer:

-

WUXI ZOZEN BOILERS

Quick Details

-

Core Components:

-

Drum

-

Steam Production:

-

Max. 3t/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZOZEN

-

Dimension(L*W*H):

-

Determined by boiler capacity

-

Weight:

-

Determined by boiler capacity

-

Name:

-

WNS oil gas steam boiler

-

Product thermal capacity:

-

3 ton

-

Working pressure:

-

1.25 Mpa

-

Available fuel:

-

Nature gas, coke oven gas, biogas, methanol, etc

-

Application field:

-

Heat suppling, chemical, food,building materials

-

Advantages:

-

Top 1 A-Class Boiler

-

Operation:

-

Automatic Control

-

Other Boilers:

-

Coal Fired Boiler Gas Fired Boiler

-

Quality:

-

100% Tested

-

Manufacturer:

-

WUXI ZOZEN BOILERS

Low Pressure Natural Gas Steam Boiler Advantage

1.

FULLY AUTOMATIC AND SAFE OPERATION:

Advanced control system enables unattended operation

2.

THERMAL EFFICIENCY≥98%:

The economizer and condenser can reuse the waste heat

3.

EASY TO OPERATE AND MAINTAIN:

Boiler internet of things +remote control + experts management

4.

ADVANCED LOW NOX BURNER:

Environmental protection, NOx emission≤30mg/Nm³

WNS series gas-fired (oil-fired) boilers are wetback fire-tube boilers with a two-pass or three-pass design. The boiler is

equipped with an advanced burner, an economizer and a condenser, which can improve the thermal efficiency to more than 98% and reduce the NOx emission to less than 30mg/Nm³. With features of compact structure, small area coverage, short installation circle

and automatic control system, the boiler can achieve unattended operation.

Digitized manufacture

* The key part such as material cutting, rolling, drilling are

proceeded by advanced CNC machining process to reduce the assemble stress and extend boiler working lifetime.

* The front and back smoke chamber plates are cut by CNC plasm a cutting machine and looks tidy and beautiful.

Easy operation and maintenance

* Fully automatically operating, with automatically adjustment and

protection of burning, water level, temperature and steam pressure.

|

Model

|

Rated steam capacity(t/h)

|

Rated working pressure(Mpa)

|

Rated steam temperature(℃)

|

|

WNS1-0.7-Y(Q)

|

1

|

0.7

|

170

|

|

WNS1.5-1.25-Y(Q)

|

1.5

|

1.25

|

194

|

|

WNS2-1.0-Y(Q)

|

2

|

1

|

184

|

|

WNS3-1.25-Y(Q)

|

3

|

1.25

|

194

|

|

WNS4-1.25-Y(Q)

|

4

|

1.25

|

194

|

|

WNS5-1.25-Y(Q)

|

5

|

1.25

|

194

|

|

WNS6-1.25-Y(Q)

|

6

|

1.25

|

194

|

|

WNS8-1.25-Y(Q)

|

8

|

1.25

|

194

|

|

WNS10-1.6-Y(Q)

|

10

|

1.6

|

204

|

|

WNS15-1.6-Y(Q)

|

15

|

1.6

|

204

|

|

WNS20-1.6-Y(Q)

|

20

|

1.6

|

204

|