- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

100 mm

-

Width of Working Table (mm):

-

1000 mm

-

Dimension:

-

4100X1100X1300mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wadley

-

Weight (KG):

-

1000

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

New Product

-

Product name:

-

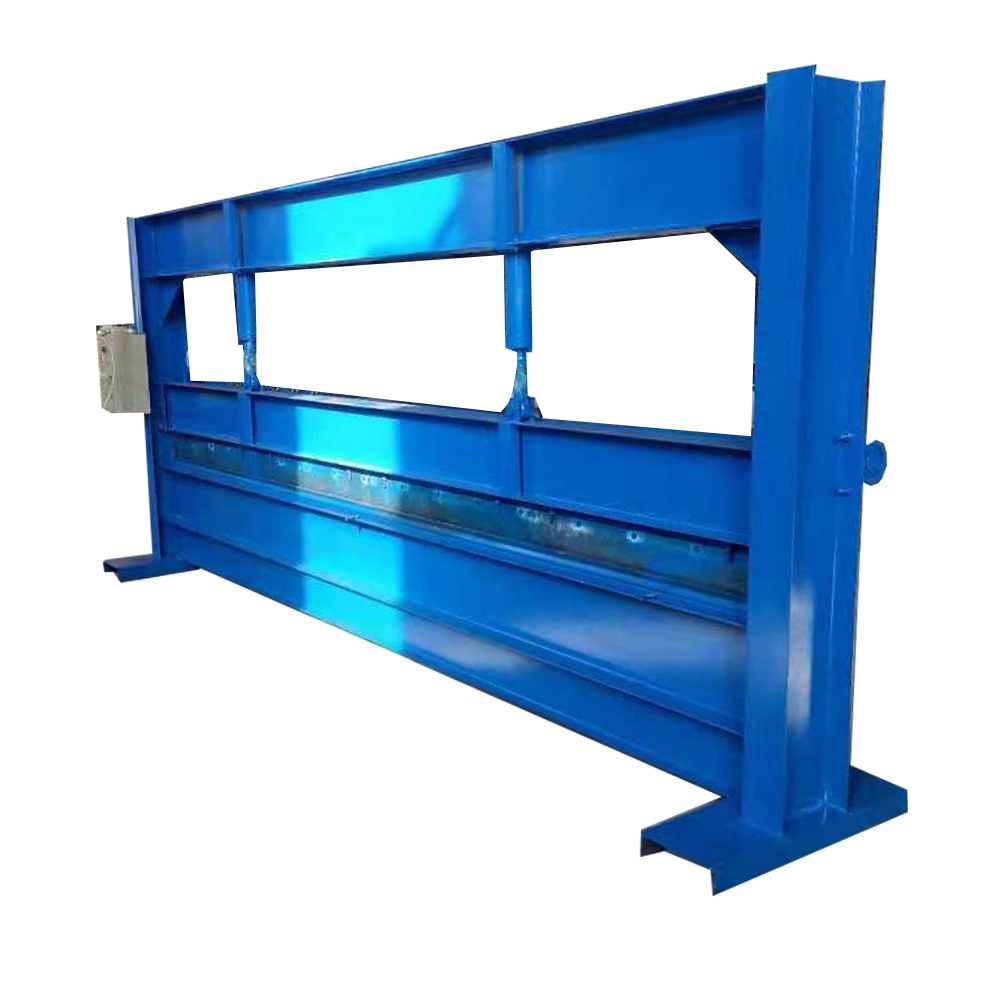

Hydraulic Cnc Bending Machine

-

Keyword:

-

Metal Bending Machine

-

Function:

-

Sheet Metal Metal Bending

-

CNC or not:

-

Nomal

-

Color:

-

Blue

-

Power:

-

3kw

-

Voltage:

-

220V/380V/415V/440V/customized

-

USE FOR:

-

Electromagnetic Sheet Bending Machine

-

Brand:

-

wadley

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

4000

-

Slider Stroke (mm):

-

150 mm

-

Throat Depth (mm):

-

100 mm

-

Width of Working Table (mm):

-

1000 mm

-

Dimension:

-

4100X1100X1300mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wadley

-

Weight (KG):

-

1000

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

New Product

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Keyword:

-

Metal Bending Machine

-

Function:

-

Sheet Metal Metal Bending

-

CNC or not:

-

Nomal

-

Color:

-

Blue

-

Power:

-

3kw

-

Voltage:

-

220V/380V/415V/440V/customized

-

USE FOR:

-

Electromagnetic Sheet Bending Machine

-

Brand:

-

wadley

Product Overview

Hydraulic Sheet Bending Machine

Hydraulic bending machine adopts an all-steel welded assembly structure, and has undergone stress treatment to ensure good rigidity and precision. The machine adopts the structure of hydraulic cylinder to control the slide block to move up and down, with fast down and fast forward control functions. The machine adopts mechanical torsion shaft or electro-hydraulic proportional valve to control the balance and synchronization of the slider. The slide rail adopts rolling or sliding, and the gap can be adjusted to make the slide move smoothly and smoothly. The machine adopts a convex, manual or pull rod type compensation table to determine the accuracy of the parts.

Product Specification

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

2000 4000 6000 mm

|

|

2

|

Max sheet thickness

|

3mm

|

|

3

|

Raw material

|

Color steel sheet or galvanized steel sheet

|

|

4

|

Angle type

|

90

|

|

5

|

Power

|

Hydraulic

|

|

6

|

Speed

|

15-20 times/min

|

|

7

|

Voltage

|

220/380 or customized

|

Hydraulic bending machine suitable for the sheet bending process of electrical switch cabinets, file cabinets, kitchen utensils,car trunk decoration and other products. It can also cut carbon steel plates, stainless steel plates, aluminum plates, copper plates, etc. Generally used in conjunction with the color steel tile press.

Product Details

Features for metal sheet bending machine,hydraulic steel plate bending machine

1. Adopt all-steel welded structure, with sufficient strength and rigidity; 2. Hydraulic drive, the oil cylinders at both ends of

machine tool are placed on the sliding block to directly drive the sliding work;

3. The slider synchronization mechanism adopts torsion shaft for forced synchronization;

4. Using mechanical block structure, stable and reliable;

5. The stroke of the slider can be adjusted quickly and manually, and the counter is displayed;

6. Oblique wedge-type deflection compensation mechanism to ensure higher bending accuracy.

1. Adopt all-steel welded structure, with sufficient strength and rigidity; 2. Hydraulic drive, the oil cylinders at both ends of

machine tool are placed on the sliding block to directly drive the sliding work;

3. The slider synchronization mechanism adopts torsion shaft for forced synchronization;

4. Using mechanical block structure, stable and reliable;

5. The stroke of the slider can be adjusted quickly and manually, and the counter is displayed;

6. Oblique wedge-type deflection compensation mechanism to ensure higher bending accuracy.

Manual bending machine.

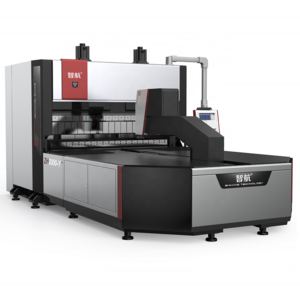

CNC bending machine

Hot Searches