PE foam has the characteristics of insulation, heat preservation, corrosion resistance and weather resistance, so it can be

applied to many equipment with high sealing requirements, used for heat preservation of oil and gas pipelines such as petroleum and chemical industry, anticorrosion, and heat preservation and insulation materials for air conditioning, refrigerator, cold storage and various adhesive belt projects.

4. Sports and leisure

PE foam is characterized by light weight, low water absorption and good floatability, which is especially suitable for water sports equipment, such as water ski board, surfboard, swimming pad, anti-sinking pad, life vest, life buoy and other water sports products.It can be used to absorb shock energy and can be made into fighting clothing, boxing gloves, protective caps, also can be used to make sports shoes and camping MATS and other materials.

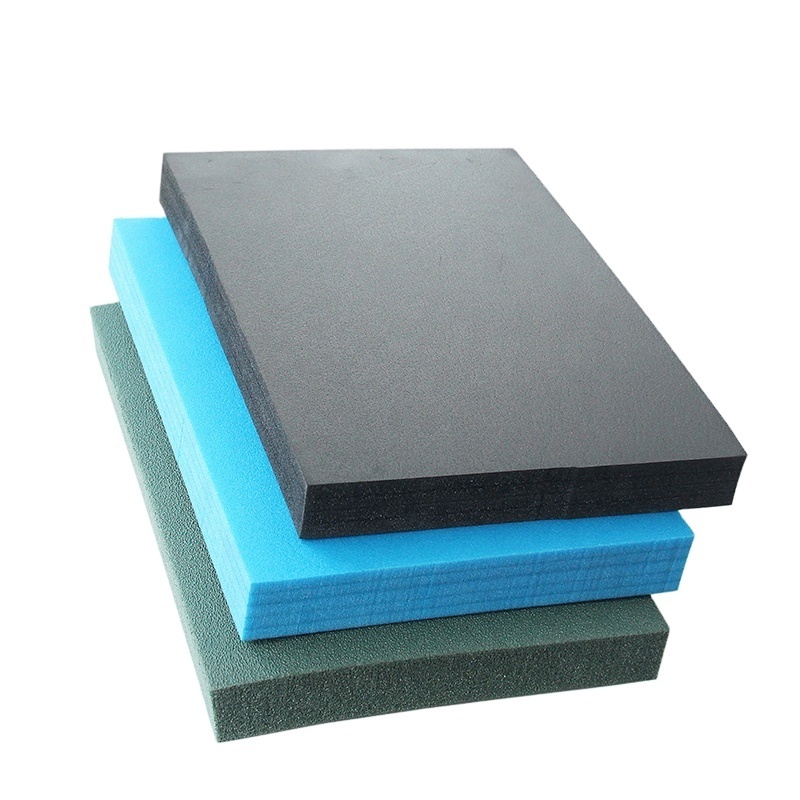

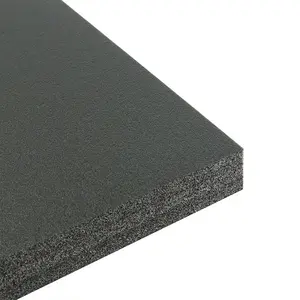

IXPE foam has smooth surface and different density, can cut, shape, print, compound, paste, with comfortable feel, non-toxic and harmless environmental characteristics.Can be used to make children's intelligence toys, sports MATS and many soft toys.

5. Buffer packaging

IXPE foam with light weight, soft texture, easy to be separated, molded and made into a variety of shapes and other physical properties, and shock absorption, anti-static and other functions, can be used as electricity, precision instruments, valuables and other anti-static packaging lining materials, also can be used as fruit anti-corrosion packaging.

Other aspects

At present, industrial designers are still seeking and exploring the wider application field of irradiated crosslinked

polyethylene foam.As the foam plastic can be made into many beautiful color and different density of products, with excellentplasticity, can be used as a variety of bags lining materials and many high-end advertising, leisure slippers, sun hat,seat cushion, outdoor sports leisure and other fields.The use of irradiated crosslinked polyethylene foams is limited to the human imagination.

Applicable processing technology

1. Hot pressing: place the baking materials in the mold of a certain shape, hot pressing, cooling and shaping.

2. Blister molding: heat the mold, then put the sheet or coil material into the mold, draw out air, and cool the mold.

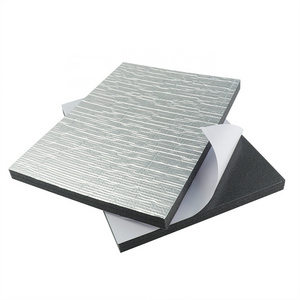

3. Hot bonding process: composite of materials of different materials with IXPE by heating.

4. Punching process: the materials are punched into the shapes required by customers through hydraulic presses, CNC engraving machines, etc.

5. Spray film technology: PE (polyethylene) is used as the medium to compound different materials with IXPE.

6. Embossing process: press the IXPE through the roller to get the grain.