SLA(Stereo Lithography Apparatus): also known as stereolithography apparatus, optical fabrication, photo solidification, or resin

printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by

layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form

polymers.Those polymers then make up the body of a three-dimensional solid.

Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate and high-resolution parts that are

capable of being used directly in end-use, low-volume production, or for rapid prototyping.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TK

-

Product name:

-

Resin Body Molds Silicone Body Stand Mould 3D

-

Material:

-

ABS/Nylon/aluminum/stainless steel/titanium

-

Processing:

-

Rapid prototyping service

-

Process:

-

Sterolithography(SLA)3D Printing 1 Piece

-

Size:

-

Customized Size

-

Tolerance:

-

+-0.1-0.2mm

-

Color:

-

Pantone/RAL number

-

Service:

-

Customized OEM/ODM

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Application:

-

Industrial Equipment, figurines, statues, models, toys

Quick Details

-

CNC Machining or Not:

-

Not CNC Machining

-

Material Capabilities:

-

Aluminum, Stainless steel, Steel Alloys, ABS and Nylon

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TK

-

Product name:

-

Resin Body Molds Silicone Body Stand Mould 3D

-

Material:

-

ABS/Nylon/aluminum/stainless steel/titanium

-

Processing:

-

Rapid prototyping service

-

Process:

-

Sterolithography(SLA)3D Printing 1 Piece

-

Size:

-

Customized Size

-

Tolerance:

-

+-0.1-0.2mm

-

Color:

-

Pantone/RAL number

-

Service:

-

Customized OEM/ODM

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Application:

-

Industrial Equipment, figurines, statues, models, toys

Product Description

What is SLA?

How does SLA work? .

Here is how the SLA fabrication process works:

1. The build platform is first positioned in the tank of liquid photopolymer, at a distance of one layer height for the surface of the liquid.

2. Then a UV laser creates the next layer by selectively curing and solidifying the photopolymer resin. The laser beam is focused in the predetermined path using a set of mirrors, called galvon. The whole cross sectional area of the model is scanned, so the produced part is fully solid.

3. When a layer is finished, the platform moves at a safe distance and the sweeper blade re-coats the surface. The process then repeats until the part is complete.

4. After printing, the part is in a green, no-fully-cured state and requires further post processing under UV light if very high

mechanical and thermal properties are required.

The liquid resin is solidified through a process called c: during solidification, the monomer carbon chains that compose the liquid resin are activated by the light of the UV laser and become solid, creating strong unbreakable bonds between each other.The photo polymerization process is irreversible and there is no way to convert the SLA parts back to their liquid form: when heated, they will burn instead of melting. This is because the materials that are produced with SLA are made of thermoset polymers, as opposed to the thermoplastics that FDM uses.

1. The build platform is first positioned in the tank of liquid photopolymer, at a distance of one layer height for the surface of the liquid.

2. Then a UV laser creates the next layer by selectively curing and solidifying the photopolymer resin. The laser beam is focused in the predetermined path using a set of mirrors, called galvon. The whole cross sectional area of the model is scanned, so the produced part is fully solid.

3. When a layer is finished, the platform moves at a safe distance and the sweeper blade re-coats the surface. The process then repeats until the part is complete.

4. After printing, the part is in a green, no-fully-cured state and requires further post processing under UV light if very high

mechanical and thermal properties are required.

The liquid resin is solidified through a process called c: during solidification, the monomer carbon chains that compose the liquid resin are activated by the light of the UV laser and become solid, creating strong unbreakable bonds between each other.The photo polymerization process is irreversible and there is no way to convert the SLA parts back to their liquid form: when heated, they will burn instead of melting. This is because the materials that are produced with SLA are made of thermoset polymers, as opposed to the thermoplastics that FDM uses.

Materials

|

Material Name

|

Description

|

Flexural Strength (MPa/KSI)

|

Elongation at Break (%)

|

HDT@0.46 MPa (°C)

|

|

Somos Watershed Black

|

Black/Dark-Grey, ABS-like

|

69MPa/KSI

|

15%

|

50%

|

|

Somos WaterShed XC 11122

|

Clear/Translucent, ABS-like

|

69MPa/KSI

|

15%

|

50%

|

|

Somos EvoLVe 128

|

White, ABS-like

|

70MPa/KSI

|

11%

|

52%

|

|

Accura Xtreme Grey

|

Grey, ABS-like

|

71MPa/KSI

|

22%

|

62%

|

|

Somos ProtoGen 18420

|

White, ABS-like

|

71MPa/KSI

|

16%

|

47%

|

|

Somos Taurus

|

Dark Gray, ABS-like

|

71MPa/KSI

|

24%

|

62%

|

Size and Tolerance

|

Description

|

Standard Resolution

|

Standard Resolution

|

|

Build envelope

|

29” x 25” x 21”

|

10” x 10” x 10”

|

|

Tolerance, XY Plane

|

+/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter.

|

+/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter.

|

|

Tolerance, Z Plane

|

+/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter.

|

+/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter.

|

|

Layer height

|

0.004"

|

0.002"

|

|

Minimum linear feature size

|

Under 0.030” are at risk and under 0.020” will not build.

|

Under 0.020” are at risk and under 0.010” will not build.

|

|

Minimum radial feature size

|

0.035"

|

0.030"

|

Surface treatment

Standard

Standard

Spraying painting

Any color if provide RAL or Pantone Number

Chrome plating

Gold / Silver

Silk Screen

Applications of Stereolithography (SLA) 3D Printing

Concept Models

The speed, accuracy, and great surface finish of SLA parts lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

The high accuracy and consistency of SLA makes it an ideal way to build large quantities of discrete or customized parts.

The speed, accuracy, and great surface finish of SLA parts lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

SLA prototyping is a fully-functional prototype, with materials that can simulate polypropylene, polycarbonate, ABS, and rigid composites.

Direct Digital Manufacturing

Direct Digital Manufacturing

The high accuracy and consistency of SLA makes it an ideal way to build large quantities of discrete or customized parts.

Recommend Products

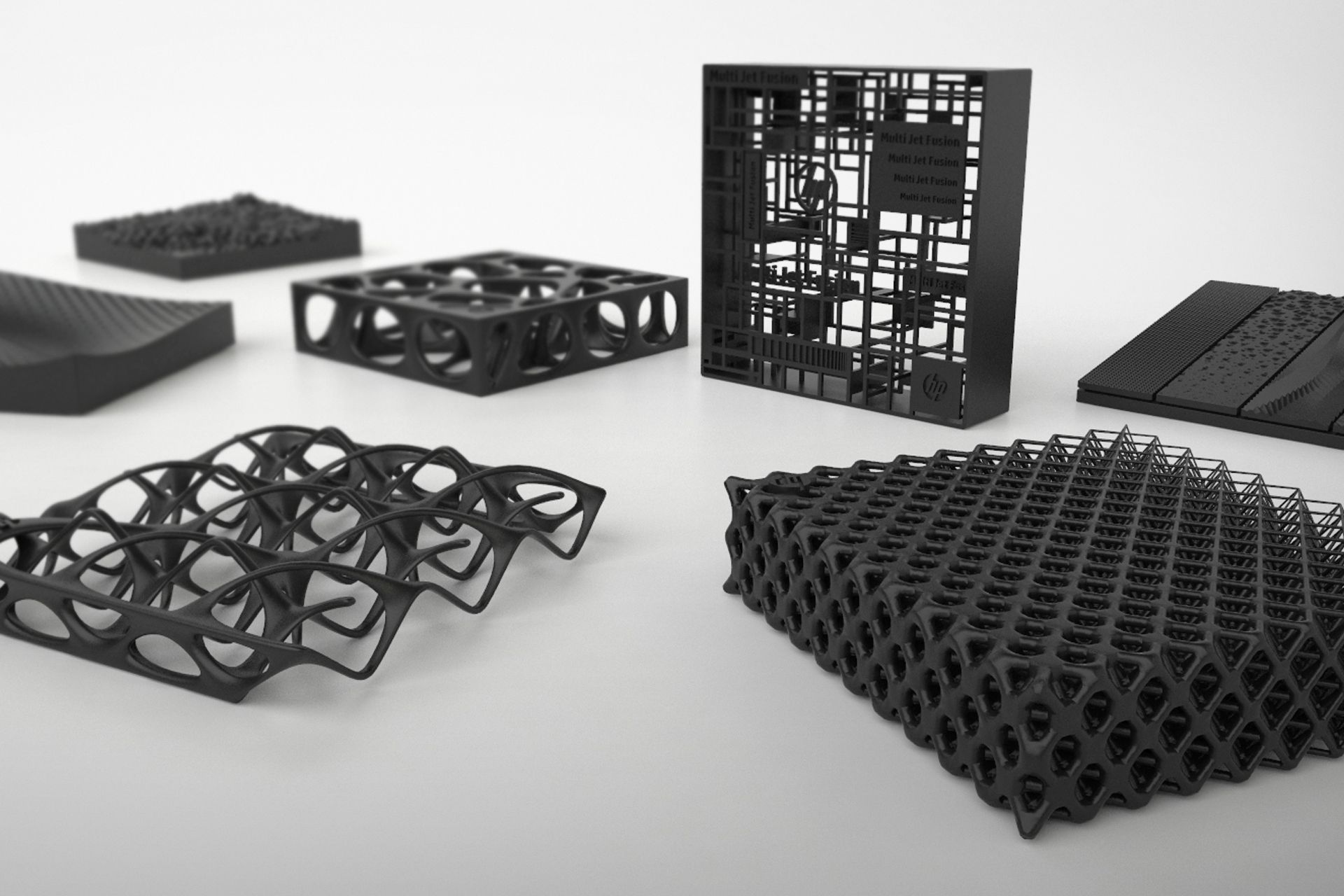

MJF 3d printing service.

Multi Jet Fusion or MJF 3D printing technology is perfect for those times when you are looking for lower porosity, short lead

times and unsurpassed surface quality. If you are manufacturing complex end-use parts and have decided to produce it in a low

volume, then MJF can be the best option for you.

Part is made by HP printer, and has got very good strength, now it is mostly in grey black color.

Material: PA11, PA12, PA2200, PA12GB

times and unsurpassed surface quality. If you are manufacturing complex end-use parts and have decided to produce it in a low

volume, then MJF can be the best option for you.

Part is made by HP printer, and has got very good strength, now it is mostly in grey black color.

Material: PA11, PA12, PA2200, PA12GB

DMLS 3d printing service

DMLS(DIRECT METAL LASER SINTERING): uses lasers to fuse powdered metals into functional prototypes and end-use parts.

Material: Titanium, Aluminium, Stainless Steel...

Material: Titanium, Aluminium, Stainless Steel...

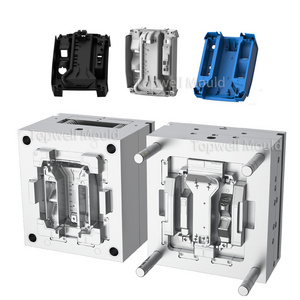

Plastic injection molding

Material: ABS, PP, Nylon, POM, PC, PMMA, PET, PVC, PET

Vacuum casting service

Silicone mold service

Material: ABS, PP, POM, PA, PMMC, PC .

Material: ABS, PP, POM, PA, PMMC, PC .

CNC machining service

Material: Aluminum, Stainless steel, Brass and harden steel.

Hot Searches