- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

none

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiaobao

-

Model Number:

-

pu sealant

-

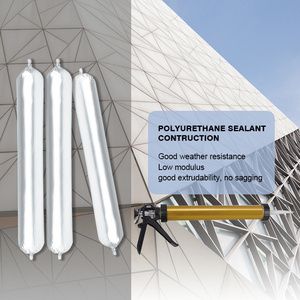

Type:

-

modified silane structure sealant, modified silane structure sealant

-

Material:

-

Polyurethane

-

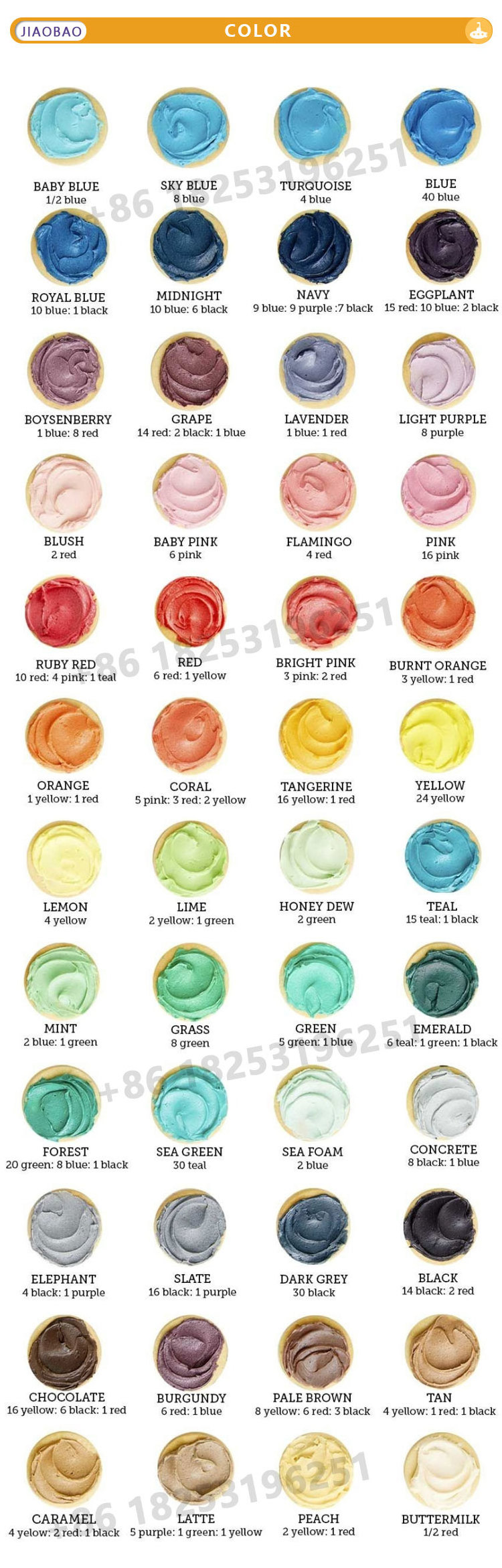

Color:

-

white ,black ,grey, clear

-

Packing:

-

310ml ,600ml

-

Shelf life:

-

12 months, 15 months

-

Certificate:

-

ISO

-

MOQ:

-

200 cartons

-

OEM:

-

Acceptable

-

Sample:

-

Available

-

Delivery time:

-

7-10 days

Quick Details

-

CAS No.:

-

none

-

Other Names:

-

PU Sealant

-

MF:

-

none

-

EINECS No.:

-

none

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiaobao

-

Model Number:

-

pu sealant

-

Type:

-

modified silane structure sealant, modified silane structure sealant

-

Material:

-

Polyurethane

-

Color:

-

white ,black ,grey, clear

-

Packing:

-

310ml ,600ml

-

Shelf life:

-

12 months, 15 months

-

Certificate:

-

ISO

-

MOQ:

-

200 cartons

-

OEM:

-

Acceptable

-

Sample:

-

Available

-

Delivery time:

-

7-10 days

PU Sealant

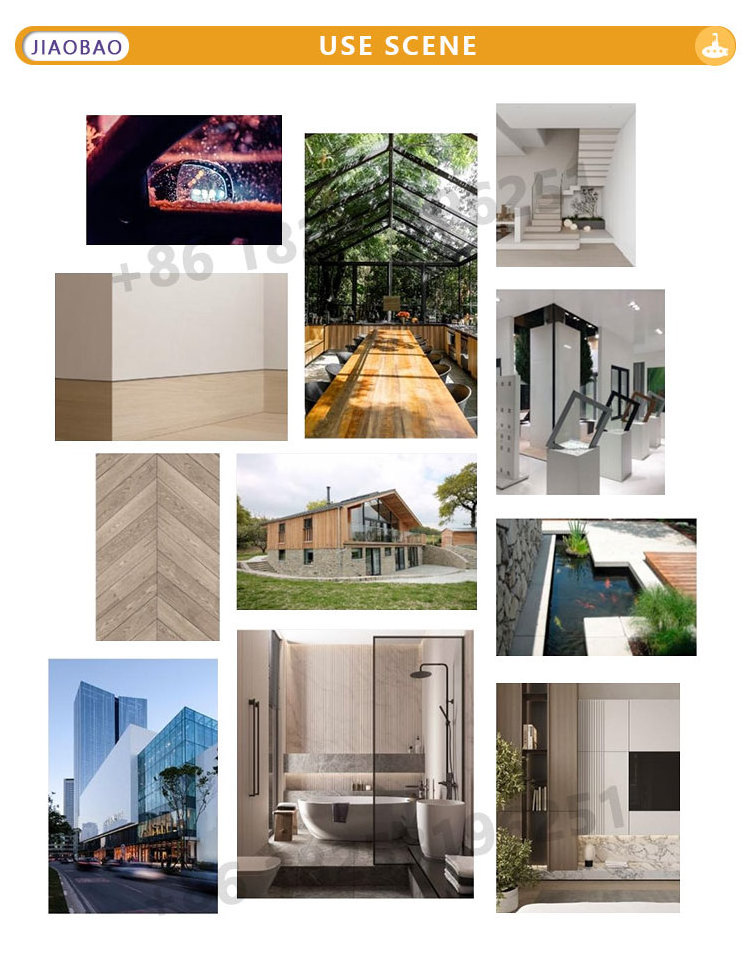

It is suitable for bonding and sealing in industries such as automobiles, rail transit, containers, ships, furniture, machinery, and building decoration that require high elasticity and strength of sealants.

Product Features

1. The white color does not turn yellow and has excellent UV resistance.

2. Isocyanate-free, solvent-free, silicone-free and PVC-free, odorless, low VOC.

3. Can be painted and has good compatibility with most paints. Ability to withstand shrinkage for long periods of time.

4. Single component, excellent shipping properties and simple construction.

5. Excellent adhesion to most plastics, rubber, metals, fiber reinforced materials, etc.

The Main Purpose

As an elastic sealant used for:

1. The bonding sealant between car windows and rubber sealing strips.

2. Seam sealing for welding of automobiles, rail transit, containers, ships, etc.

3. Sealing in electrical appliances, equipment, air conditioners, equipment, furniture and other industries.

4. Purification workshop, complete sealing of blinds and ceilings.

Used as adhesive for:

1. Bonding of electronics, plastics, air conditioning and ventilation ducts.

2. Bonding of metal structures of car bodies, train carriages, containers, and mechanical equipment.

3. Bonding of vehicle and RV side panels and roof leather.

Usage Restrictions

1.Surface treatment

The bonding surface should be clean, dry and free of grease, oil and dust. Applying primer to surfaces that are difficult to bond (such as PP/PU materials, etc.) can increase the bonding effect.

2.Construction

Hard packaging: just cut the mouth open.

Soft packaging: Put glue into the glue gun and cut off the sealing mouth.

Cut the glue nozzle according to the designed strip shape. In order to achieve a satisfactory sealing effect, a manual hard-tube glue gun, a piston-type pneumatic glue gun or a glue pump equipment is required. If MS1983 will come into contact with polyurethane adhesive or coating, the polyurethane must be completely cured before MS1983 can be used to fill or bond the joints.

3. Trimming and finishing must be carried out before the surface is dry, and the trimming agent or lubricant must be tested for suitability/compatibility in advance.

4. Clean and reuse

The cured MS1983 can be removed from tools or equipment with appropriate solvents. Once cured, it can only be removed mechanically. Hands and exposed skin should be immediately treated with appropriate industrial hand sanitizer and water after being stained with glue. Clean. Any excess sealant that has not been used can be stored in a sealed package, and the cured portion of the surface can be removed before next use for reuse. But it is needed for usability testing.

5. Surface paint (when needed)

Ms1983 can be sprayed before and after surface drying. A compatibility test should be done before painting. It should be noted that the thickness and hardness of the paint layer may weaken the elasticity of the glue and create the possibility of cracking of the paint layer.