- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

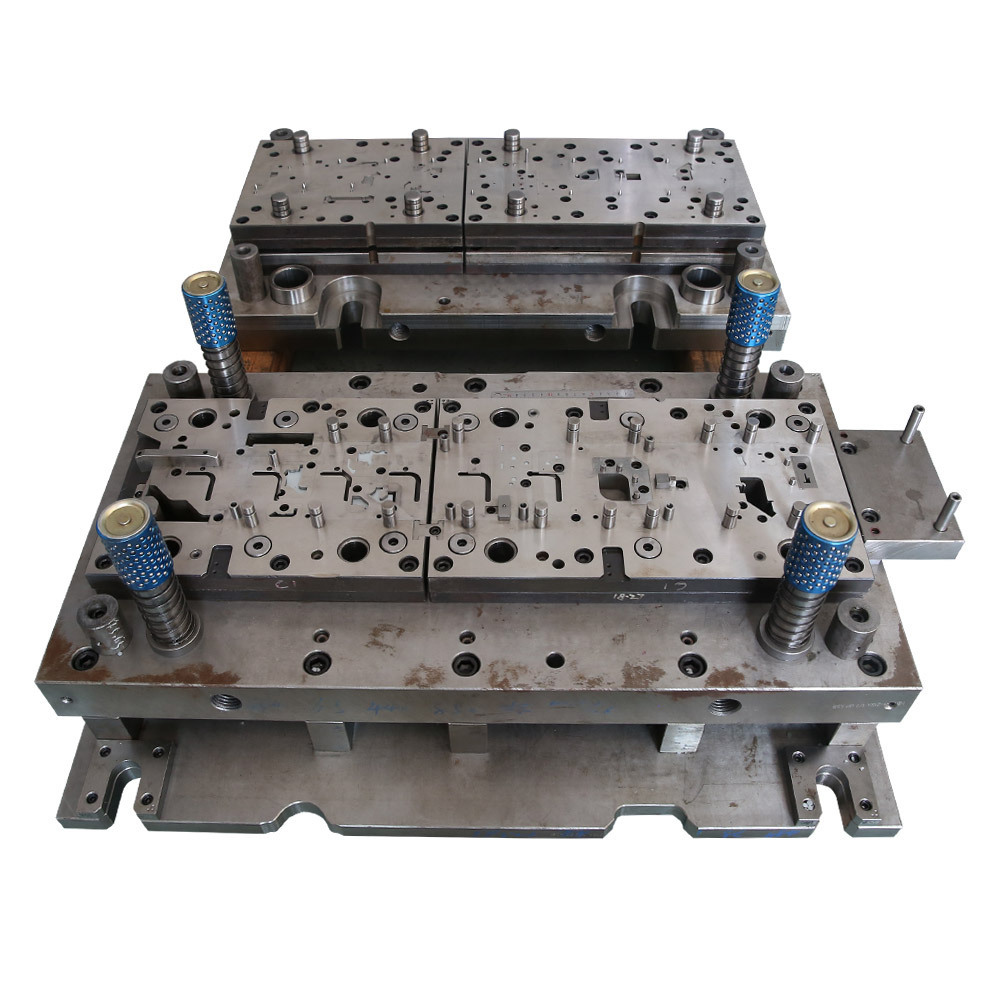

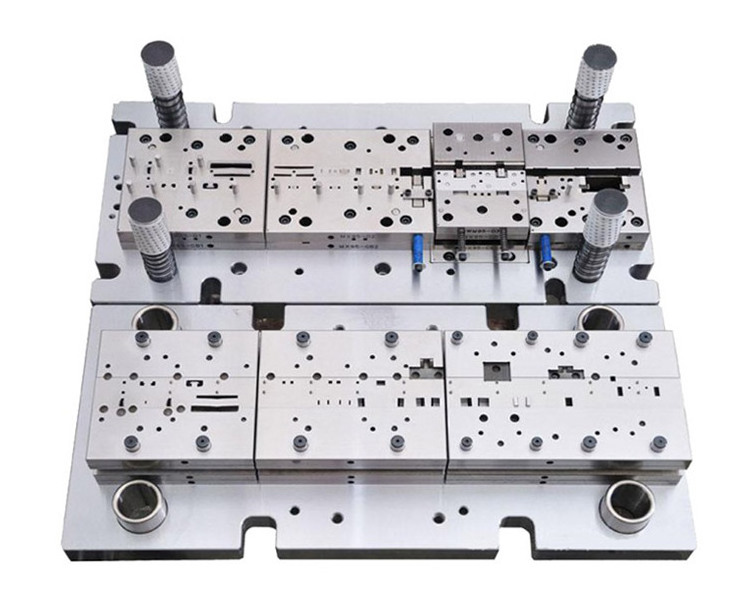

Stamping tools

-

Product Name:

-

sheet metal stamping punch mould tool

-

Material:

-

CRS, Stainless stell, Copper, Brass, Aluminum

-

Name:

-

sheet metal stamping mold

-

Type:

-

progressive

-

Mould life:

-

3000kshots

-

Process:

-

Wire Cut

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

China

-

Brand Name:

-

NEWSKY

-

Model Number:

-

Stamping tools

-

Product Name:

-

sheet metal stamping punch mould tool

-

Material:

-

CRS, Stainless stell, Copper, Brass, Aluminum

-

Name:

-

sheet metal stamping mold

-

Type:

-

progressive

-

Mould life:

-

3000kshots

-

Process:

-

Wire Cut

|

Product Name

|

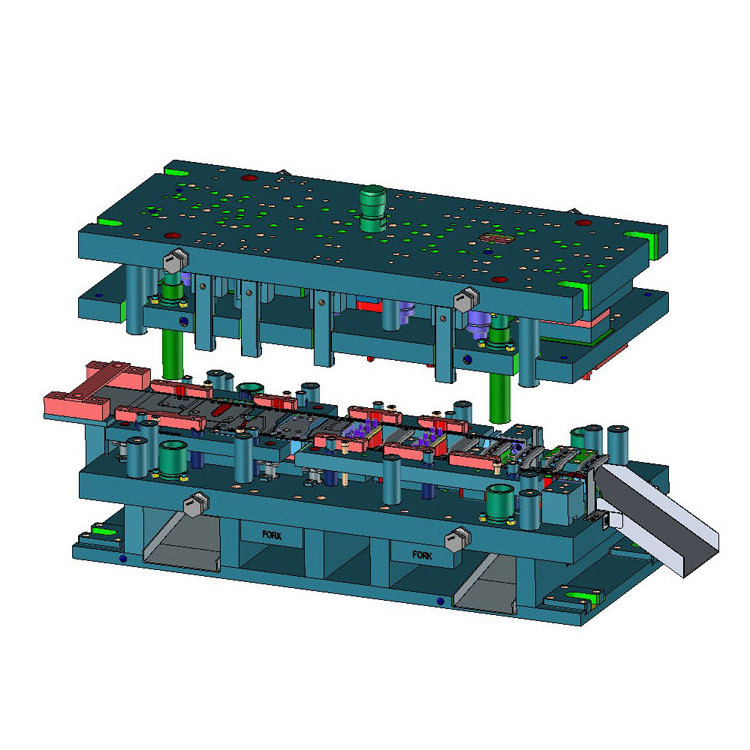

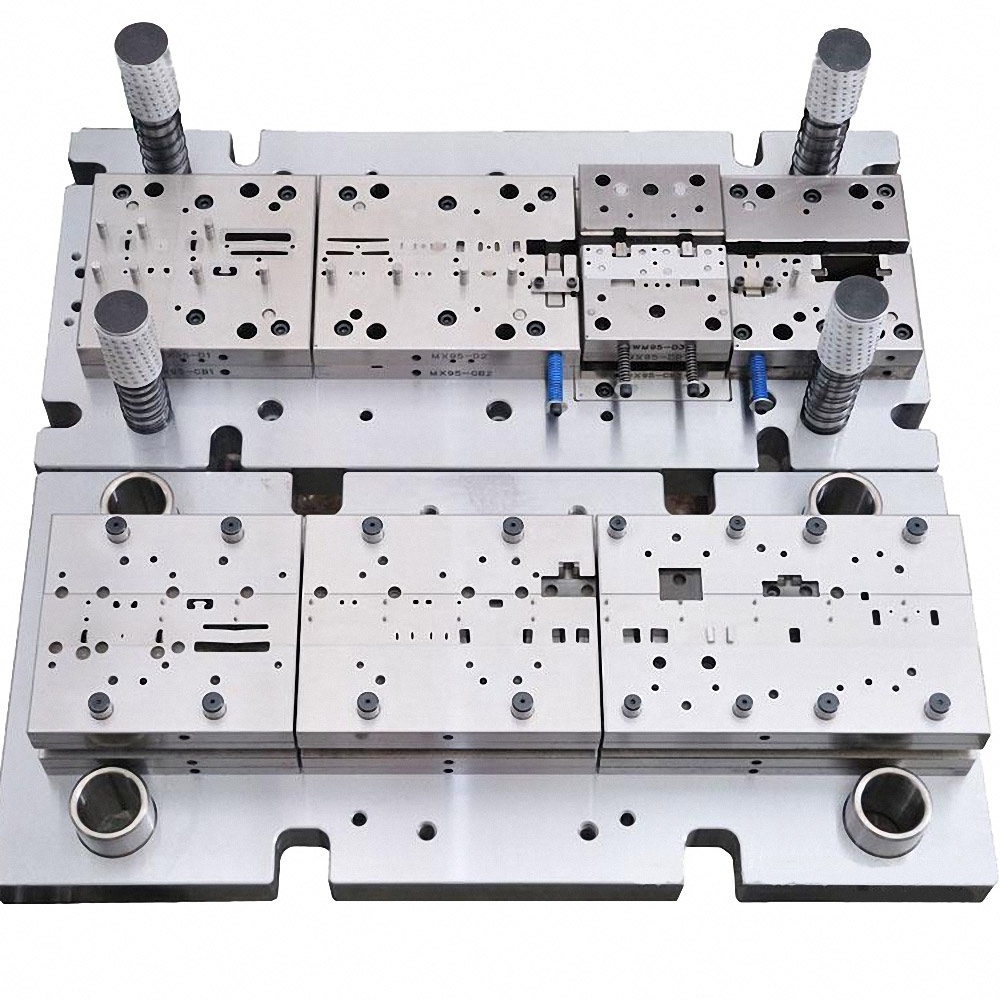

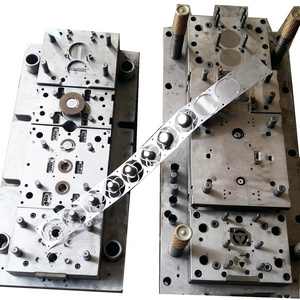

15 years experience customized cheap sheet metal stamping punch mould tool with Export Certified For Kitchen appliance

|

|

Material

|

Die plate:SKD11,Stripper plate:P20 or As specified by the customer

|

|

Color

|

Natural color

|

|

Standard

|

DIN GB ISO JIS BA ANSI

|

|

Design file format

|

dwg, dxf, step, x_t, top, igs

|

|

Tooling manufacturing cycle

|

3 Weeks to 10 Weeks

|

|

Forming way

|

Punching, Blanking, Bending, Burning, Deep drawing, Forming etc.

|

|

Press machine tonnage

|

30T to 315T

|

SHENZHEN NEWSKY TECHNOLOGY CO.,LTD.

NEWSKY was founded in 2004, located in shenzhen city. It is conveniently located between Hong Kong, guangzhou, dongguan and

zhuhai.

Newsky is an expert in metal stamping die and metal stamping products. We specialize in cold forging progressive, shear free, thin

material stamping, micro stamping and deep stamping. Business processes are based on the processing of samples or drawings.

Customers cover the automotive and electromechanical industries.

NEWSKY's concept is "one-stop service".This means providing comprehensive solutions to downstream customers.Our customers only

need to provide the technical requirements, and NEWSKY will do the rest and provide the customer with the complete solution, from

prototypes, tool development, samples, pilot production to mass production. And our customers can focus on their core business.

Newsky was founded by experienced professional managers who had worked at prestigious international companies.NEWSKY knows exactly

what customers want. "High quality, low cost, customer service" naturally become the core competitiveness of the new sky.

The company's vision is "to be a partner with customers". We are willing to work closely with customers at home and abroad for

mutual benefit and common development.

Welcome to enquiry!

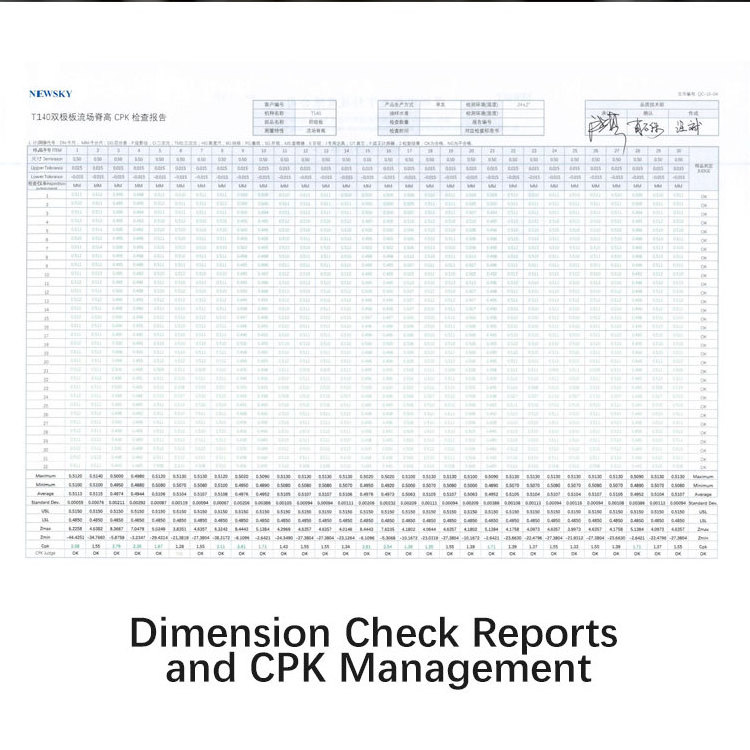

2. Strict processing quality control

3. 100% inspection before shipment.

4.Promptly reply to enquiries within 24 hours;

5. Try our best to solve problems or questions for you, with our professional team;

6. The best price for the same quality, second order 2% off, benefit customers via cost analysis.

7. Quick response, within 24-48 hours, to 8D reports of abnormality, or dealing of defective products;

Q: Are you a factory or trading company?

A:

We are a factory established in 2004, producing metal stamping parts for more than 16 years.

Q: What are your main products?

A: We specialize in manufacturing metal stamping tool ,metal stamping parts.sheet metal parts,cnc machining part and welding structural parts etc.

Q: What is surface treatment do you have?

A: Dacromet ,powder coating,Zinc plated, nickel plated, tin plated, brass plated, silver plated, gold plated, anodizing, salt fog test etc. Due to we are focus on stamping tools and metal stamping parts, surface treatment is done through suppliers.

Q: Can I get the samples?

A: Yes, sample order is available for quality check and market test, and it will be freight collect payment. If simple sample, we will not charge cost; If OEM/ODM samples, we will charge for the sample cost.

Q: What is the MOQ?

A:The MOQ is 1000pcs when have the inventory.

Q:What's the delivery time?

A:The stamping tool manufacturing cycle is 20-50Days, standard stamping parts is 3 to 10 days after paymen. If OEM or make the tooling, we will confirm the delivery time with you.

Q: What's your payment term?

A: we advise 30% T/T deposit, balance be paid before shipment.

Q: Do you received OEM/ODM?

A:

Yes. We have more than 16 years OEM/ODM experience since 2004.

Packing Details :

Tooling package: 1 tooling 1 wooden case;

Stamping package: Provide reliable packaging according to product features.