- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

510*390*100

-

Weight (KG):

-

38 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

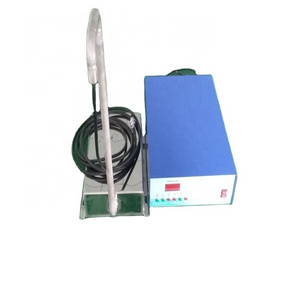

Immersible Ultrasonic cleaner:

-

Immersible ultrasonic vibration plate

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Immersible Ultrasonic Vibration Plate

-

Power:

-

1200

-

Dimension(L*W*H):

-

510*390*100

-

Weight (KG):

-

38 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Immersible Ultrasonic cleaner:

-

Immersible ultrasonic vibration plate

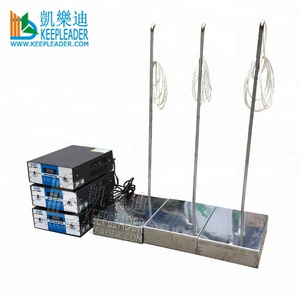

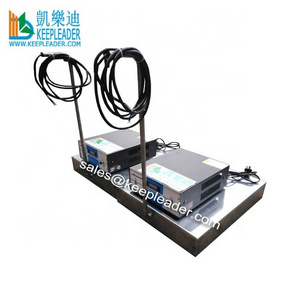

Immersible Ultrasonic Vibration Plate Cleaning Machine

Immersible Ultrasonic Vibration Plate Cleaning Machine

|

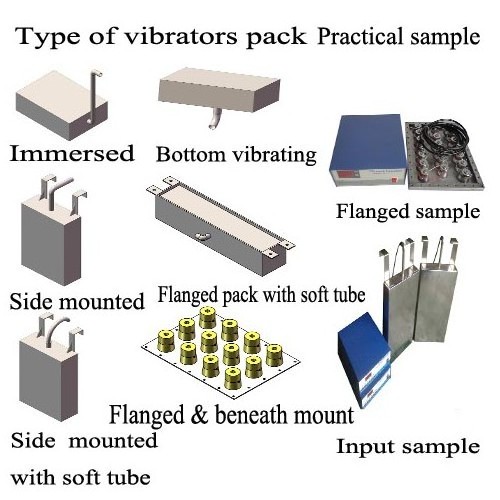

Immersible Ultrasonic Vibrators Pack |

||||||

|

Application |

||||||

|

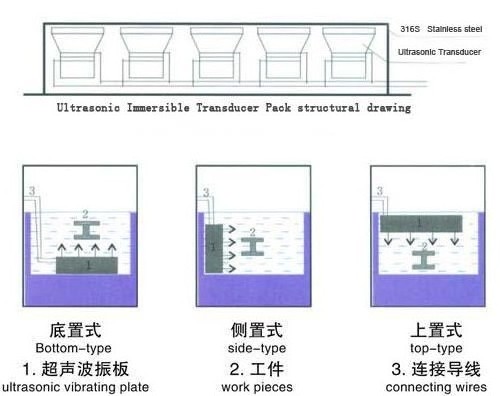

Immersible Ultrasonic Vibration Plate Cleaning Machine also called ultrasonic seismic plate, ultrasonic earthquake plate, ultrasonic vibrators pack, which is consisted by ultrasonic vibrators pack, ultrasonic generators, is suitable for cleaning electroplating parts, horologe parts, hardware machinery parts, polyester filtering cores, semiconductor wafer. Tools, lens, frames, Jewelry, glass, medical equipment and other industrial metal, glass, plastic parts When the standard model ultrasonic cleaning machine cannot adapt to some special working environment, you can choose the immersible ultrasonic cleaner, the mounting position can be optional, top, bottom, side mounting are all possible |

||||||

|

Features |

||||||

|

Consist of vibrators pack, ultrasonic generator, both are connected by single wire, convenient to locating and removing All make of stainless steel, the vibrating side is chrome plated The Vibrators are made-in-Japan, high power output, can 24 hours continue working Using imported high strength glue, ultrasonic vibrators also locked by welded screws Vibrating pack is made of SUS3.4, 2.0mm. the vibrating side is made of SUS316L,2.5mm The vibration pack is welded by laser, more liable for leakage-proof Vibration plate will never overheating, no leakage, no whistles noise Ultrasonic generator frequency has the fine-tune function, adjusting scope is 2% The generator build-in the function of frequency seep, power regulation, timer, digital display Timer control from 0~59 minutes and 59 seconds Generator also can build romote control, memory function Using separate excitation technology, the power is more than traditional circuit 15% |

||||||

|

Specifications |

||||||

|

model |

KLE-1012P |

KLE-1018P |

KLE-1024P |

KLE-1030P |

KLE-1048P |

|

|

power |

600W |

900W |

1200W |

1500W |

2400W |

|

|

Frequency |

25/28KHz |

25/28KHz |

25/28KHz |

25/28KHz |

25/28KHz |

|

|

Size |

360*275*100 |

420*320*100 |

510*390*100 |

520*450*100 |

1000*480*100 |

|

MFR: KEEPLEADER has modified and designed Immersible Ultrasonic Vibration Plate Cleaning Machine to accommodate our customers’ unique and special requirements, please contact KEEPLEADER for tech support

Troubleshooting of ultrasonic cleaning process

How to use ultrasonic cleaning machine correctly and efficiently, there are many professional suggestions collected from KEEPLEADER’S training course, herein, hope this post can acknowledge more companies, who are using ultrasonic cleaning in their production process

01: In first shift working, our ultrasonic cleaning machine works not so expected, why is this so?

Ans: everyone clearly knows that ultrasonic cleaning must use aqueous media or chemical solution, this possibility of dissolved gases hided, in ultrasonic process, as high-frequency sound waves travel through aqueous media, areas of compression and rarefaction occur, during rarefaction, there is negative pressure, with enough loudness (sufficient amplitude), cavitation, voids or tear in the cleaning liquid occur, these are sometimes referred as cavitation or vacuum bubbles, when the bubbles collapse or implode during compression, the energy (pressure and localized temperature) associated with this collapse is responsible for the cleaning power of ultrasonic

In the first shift cleaning, it is a near certainty that the aqueous media contains dissolved gases, this means that the ultrasonic bubbles formed during rarefaction contain dissolved gases rather that a near-vacuum, the bubbles are “cushy”, so they do not collapse efficiency, turning on the ultrasonic for a few minutes prior to processing a product releases the dissolved gases, if the ultrasonic machines have not been used for a whole, you should degas cleaning chemistries, or if fresh cleaning chemistry has been added, if in doubt, then degas

02: We have a small unheated ultrasonic tank, as the day goes on, cleaning efficiency keeps getting better, is this all due to degassing?

Ans: Most of the improvement is probably due to temperature effects, in fact, as the day progresses, the ultrasonic transducers generate heat, causing the temperature in the ultrasonic tank to increase, unless a temperature-controlled system is used, as the temperature increase, ultrasonic cleaning performance tents to improve, up to a point, the maximum performance temperature depends on the cleaning chemistry, for water, the maximum temperature about 55 degree, as the temperature increase, the viscosity of cleaning chemistry decreases, so cavitation becomes increasing effect, in addition, as the temperature increases, cleaning effectiveness tents to increase, whether or not ultrasonic are used

03: Why does ultrasonic performance decline later in the day?

Ans: When the liquid reach its boiling point caused by heating and inherent ultrasonic produced, for reason related to the degassing issue, the higher temperature, the higher the vapor pressure of the liquid, so the cavitation bubbles has more vapor, the bubbles become “cushy” and they do not implode effectively

04: The effectiveness of our ultrasonic cleaning line seems to vary throughout the day, why do we notice the worst problems when our throughout is highest?

Ans: The tank size usually design its average cleaning volume, if the cleaning basket is overloaded, the ultrasonic energy cannot reach any corner because of ultrasonic intensity is dampened during travelling ,

05: How to choose correct ultrasonic frequency?

Ans: For small components and precision parts, KEEPLEADER suggest 40khg or bigger, the higher frequency, the bubbles is smaller, which can have good penetrating performance into tiny blind holds, recesses, cracks, and gentle ultrasonic rubbing force, can well protect the substrate of cleaning parts, but the smaller bubbles cannot contain higher temperature and pressure, so, for big size parts or heavy grease, 28khz play a good cleaning role, up to one point, this depends on the your current and anticipated production line and process requirements

06: Our parts have heavy grease, we toss parts into the ultrasonic tank, leave them there for hours, How long do we need to clean them?

Ans: Ultrasonic cleaning time usually set in minutes, 3 to 5 minutes is normal, but, tank normally heated or chemical added to reduce the water surface tension and improve the bubble forming, many factories also using spraying process to speed up the cleaning, anyhow, the cleaning time is not hours, if have somehow, the chemical added might not be optimal, you need to adjust the change it, or ultrasonic transducer might be malfunctioning, the placement of the transducer or power density might be incorrect for the task at hand, the parts might not be suspended properly, so that parts are shadowed

07: If plastic tank, basket or fixture is ok for ultrasonic cleaning system?

Usually, no plastic in ultrasonic cleaning should be better, as mentioned previous, ultrasonic contains pressure and hot energy in vacuum bubbles, which implode when touching the substrate of cleaning parts, plastic tank, basket or fixture can soften and dampen the suction force, so, stainless steel, metal basket is recommended, we notice that some companies toss their parts into the plastic tank with ultrasonic vibrations in testing and erroneously concludes that their tank is workable, so not that, KEEPLEADER also advise you to consider your mesh size, try to use big mesh size in solid stance

08: Can we use acetone in ultrasonic cleaning for small-scale?

Inflammable solvent is strongly forbidden in ultrasonic cleaning, acetone is over its flash point at ambient temperature, ultrasonic is ignition source, most of ultrasonic cleaning machine is designed for organic, non-inflammable solvent cleaning

09: Conclusions

Efficient ultrasonic cleaning depends on its cleaning quality and productivity, for ordering, you need to evaluate what ultrasonic cleaning system can do, even the most important is what cannot do, take a step back, look at your whole cleaning line, where need to be improved and changed