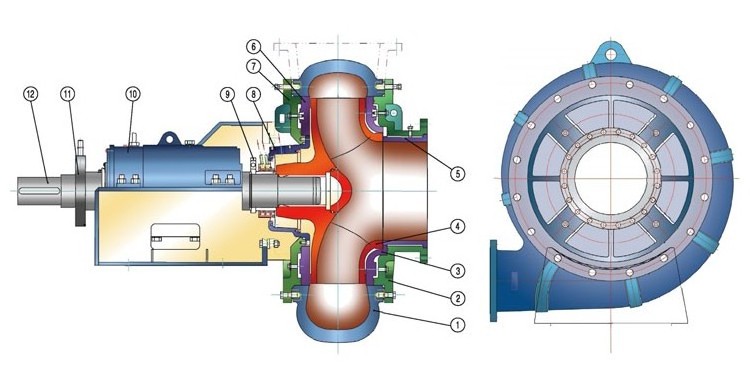

The impeller generally has three vanes or five vanes and wide application range.It is made of wear-resistant high chromium alloy cast iron(hardness≥58HRC,impact toughness≥9J/cm 2 ).The impeller is fixed on the pump shaft with double thread,and the thread tolerances are inspected according to the pitch diameter of thread.Disassembly rings are installed at the rear of the shaft sleeve to make maintenance easy.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

E-TOUCH

-

Model Number:

-

350WN

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

20-500 HP/As customer request

-

Cable Length:

-

based on model

-

Outlet Size:

-

350mm

-

Power:

-

As customer request

-

motor:

-

As customer request

-

Capacity:

-

1800-2200m³/h

-

Head:

-

40-65m

-

NPSHr:

-

<4

-

efficiency:

-

70-76%

Quick Details

-

Application:

-

Marine, dredging, mining

-

Pressure:

-

High pressure

-

Voltage:

-

380v

-

Warranty:

-

1 year

-

Brand Name:

-

E-TOUCH

-

Model Number:

-

350WN

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

20-500 HP/As customer request

-

Cable Length:

-

based on model

-

Outlet Size:

-

350mm

-

Power:

-

As customer request

-

motor:

-

As customer request

-

Capacity:

-

1800-2200m³/h

-

Head:

-

40-65m

-

NPSHr:

-

<4

-

efficiency:

-

70-76%

Product Application

WN series wear-resistant dredge pump,a new type of slurry pump,is designed to solve the situation wherr China's rivers and lakes are badly in need of dredging.N series dredge pump is single-stage,single-suction,horizontal and centrifugal pump.It has many features:light weight,high wear resistance,excellent dredging performance,reasonable structure and cost-effective.So this pump can meet the requirements of dredgers completely.

At present,the 600mm,700mm,800mm,900mm caliber dredge pumps manufactured by our company have been successfully applied on large dredgers of many Waterway Bureau.

Among the wet parts,the impeller,front liner plate and rear liner plate are all made of wear-resistant high chromium alloy cast iron (hardness≥58 HRC);casings are made of wear-resistant and compression-resistant alloy.The wet parts can be made of different materials to meet the requirements of different mediums.

|

Type

|

Capacity

(m3/h)

|

Head

(m)

|

Speed

(r/min)

|

Efficiency

(%)

|

Inlet Dia

(mm)

|

Outlet Dia

(mm)

|

|

200WN

|

800-1000

|

40-60

|

750-900

|

59-65

|

250

|

200

|

|

250WN

|

1000-1500

|

40-65

|

550-700

|

60-73

|

350

|

250

|

|

300WN

|

1800-2200

|

40-65

|

400-550

|

72-76

|

350

|

300

|

|

DT350WN

|

1800-2900

|

40-61

|

450-560

|

78-84

|

450

|

350

|

|

400WN

|

2500-3300

|

40-62

|

490-600

|

73-80

|

500

|

400

|

|

450WN

|

3200-3800

|

40-67

|

350-500

|

70-76

|

600

|

450

|

|

DT450WN

|

3300-4200

|

42-67

|

400-505

|

76-84

|

520

|

450

|

|

500WN

|

4500-5500

|

40-66

|

350-450

|

70-75

|

650

|

500

|

|

DT500WN

|

4500-6000

|

45-67

|

400-470

|

79-84

|

600

|

500

|

|

600WN

|

6000-8000

|

56-62

|

450-470

|

80-83

|

600

|

600

|

|

700WN

|

9000-11000

|

48-68

|

320-380

|

81-84

|

760

|

700

|

|

WN series dredging pump performance parameters

|

|

|

|

|||

Main Features

1) Advanced hydraulic model,CAD-aided design,high efficiency and remarkable energy-saving effect.

2) Strong flow capacity.The pump can pump gravel,high plastic clay lumps and so on.Dredge pump is generally equipped with three vanes or five vanes,used to handle different particle size respectively.

3) Strong matching capacity.The diesel engine and the motor are both available.

4) Small size,light weight.

The whole machine and every component of the dredge pump all adopt optimization design and strength analysis,this can greatly reduce the pump weight by minimizing unnecessary auxiliary structure and process structure on the premise of satisfying the performance and application requirements.

5) Stable running,small vibration and low noise.

6) Simple structure,easy to dismantle and maintain.

7) The parts have long service life.

8) Reliable seal,no leakage.

9) The whole machine has high reliability and remarkable economic benefits.

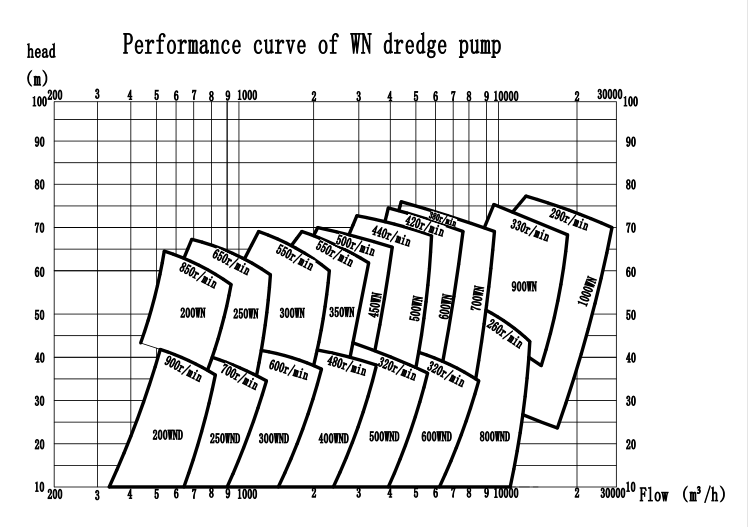

10) The steep drop type of performance curve.

|

The structural drawing of N series ,wear-resistant dredging pump

|

|

|

|

|||

|

1. Pump Casing

|

2. Front Cover Plate

|

3. Front Liner Plate

|

4. Impeller

|

|

5. Import Lining

|

6. Rear Liner Plate

|

7. Rear Cover Plate

|

8. Seal Assembly

|

|

9. Disassembly Ring

|

10. Support

|

11. Jigger

|

12. Shaft

|

Impeller

Volute casing

The volute casing is made of wear-resistant and compression-resistant alloy(hardness≥56HRC,impact toughness≥8J/cm 2 ).Advanced smelting technology combined with casting process and heat treatment process guarantees smooth casting surfaces and reliable internal qualiyt.

The bulge test will be carried out after molding,and the test pressure is 2 times of the discharge pressure of the pump.If there no leakage after 20 minutes,strength and tightness,strength and tightness pressure test reports can be issued.

Liner plate

The liner plates are made of wear-resistant high chromium alloy cast iron(hardness≥56HRC,impact toughness≥8J/cm 2 ).

E-Touch regards customer as the foundation,the customers' satisfaction is our permanent persuit.E-Touch has established perfected strict quality assurance system and service assurance system.E-Touch strictly inspects each product before they leave the factory strictly dwording to the international inspection standard.E-Touch performs each contract strictly,delivers its products on time and managers to supply the spare parts in time.E-Touch sincerely supplies customers with first class products,first quality and first service.