- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

500* 400* 400mm

-

Weight:

-

600 KG, 50kg

-

Product name:

-

ceramic ball mill

-

type:

-

1L/2L/3L/5L/10L/15L/20L

-

Application:

-

Mineral processing, material mill

-

Packing:

-

Wooden case

-

Testing:

-

Before delivery

-

Motor power:

-

120w

-

Keywords:

-

Lab ball mill

-

Keywords 1:

-

Small ball mill

-

Local Service Location:

-

None

Quick Details

-

Capacity(t/h):

-

4

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

jinchuan

-

Dimension(L*W*H):

-

500* 400* 400mm

-

Weight:

-

600 KG, 50kg

-

Product name:

-

ceramic ball mill

-

type:

-

1L/2L/3L/5L/10L/15L/20L

-

Application:

-

Mineral processing, material mill

-

Packing:

-

Wooden case

-

Testing:

-

Before delivery

-

Motor power:

-

120w

-

Keywords:

-

Lab ball mill

-

Keywords 1:

-

Small ball mill

-

Local Service Location:

-

None

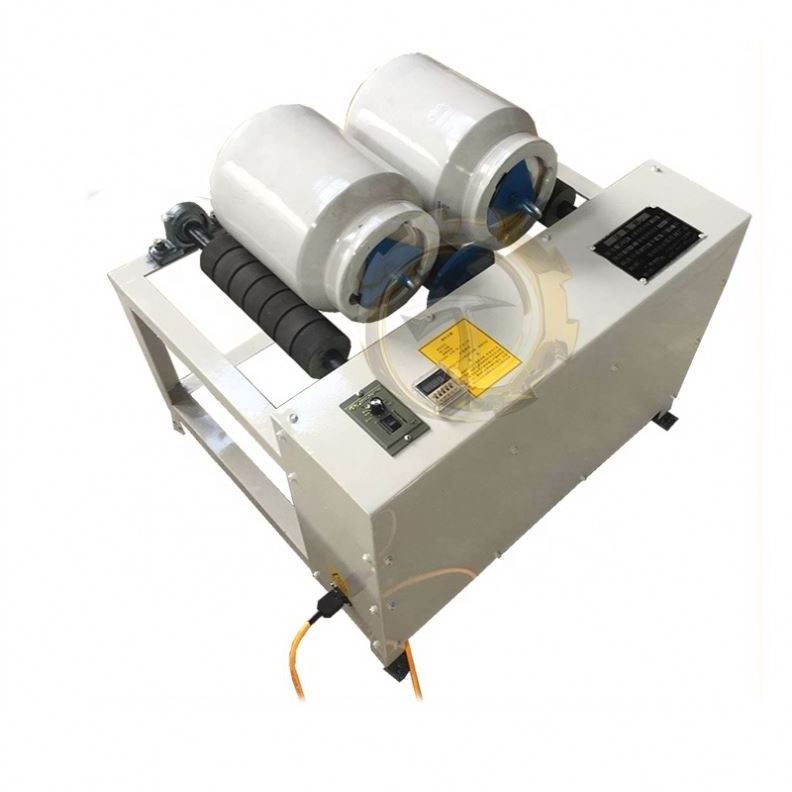

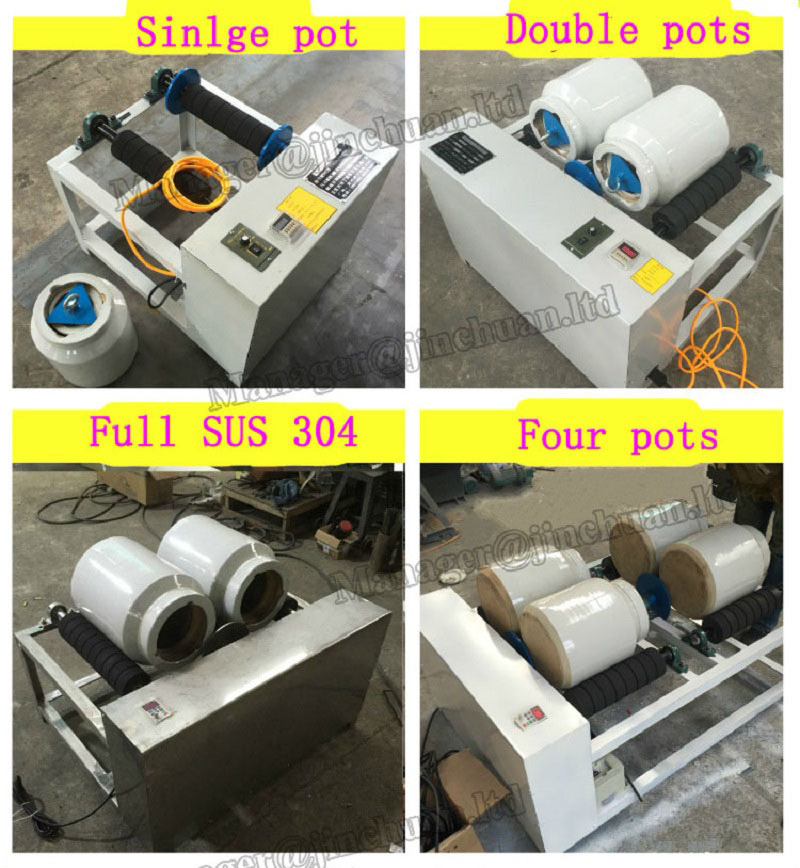

Hot new products high quality ceramic ball mill small type for lab

Ceramic ball mill used in geology, mineral, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments, suitable for electronic ceramics, structural ceramics, magnetic materials, catalyst, fluorescent powder, pigment, paint, dressing, medicine, glass, phosphor, rare earth polishing powder, glass powder, electronic Zinc Oxide fuel cell, varistors, piezoelectric ceramics, nano materials, ceramic disc capacitor, MLCC, thermistor (PTC, NTC), ZnO varistor, dielectric ceramic, alumina ceramic, zirconia ceramics, fluorescent powder, zinc oxide, cobalt oxide powder, Ni-Zn ferrite and Mn-Zn ferrite. Production areas

1.General dry grinding ball milling powder according to the raw material feed particle size corresponding ball mill, such as feed particles can choose the larger diameter ball mill, according to the milling time increasing fineness is high, the general material can reach more than 600 mesh.

2. Wet grinding: wet grinding process can effectively increase the fluidity of material in ball mill, and can reach more than 1000 mesh according to ball milling time and process fineness.

3. Speed: speed of conventional ball milling can speed 50-70r/min, of course, is not suitable for all materials, commonly used methods for determining speed milling tank ball mill ball mill the louder the sound proof in the tank on the material milling effect is more obvious.

4. Tming: timer adopts digital display timing, setting time is 1-99 hours

It is necessary to unplug the socket and set the time before setting

|

Model |

Jar quantity |

Jar volume |

Single jar maximum grinding capacity |

Speed(r) |

Motor power |

|

WZM- 1L -1 |

1 |

1L |

200g |

100 |

120W-2 |

|

WZM- 2L -2 |

2 |

2L |

500g |

0-95 |

550W-2 |

|

WZM- 3L -1 |

1 |

3L |

2KG |

90 |

120W-2 |

|

WZM- 5L -1 |

1 |

5L |

4KG |

80 |

120W-3 |

|

WZM- 3L -2 |

2 |

3L |

2KG * 2 |

90 |

120W-5 |

|

WZM- 5L -2 |

2 |

5L |

4KG * 2 |

80 |

120W-5 |

|

WZM-10L -2 |

2 |

10L |

8KG * 2 |

70 |

550W |

|

WZM-15L -2 |

2 |

15L |

10KG * 2 |

68 |

550W |

|

WZM-20L -2 |

2 |

20L |

15KG * 2 |

65 |

750W |

|

WZM- 3L -4 |

4 |

3L |

2KG * 4 |

80 |

550W |

|

WZM- 5L -4 |

4 |

5L |

4KG * 4 |

60 |

750W |

|

WZM-10L -4 |

4 |

10L |

8KG * 4 |

60 |

1.5KW |

|

WZM-15L -4 |

4 |

10L |

10KG * 4 |

60 |

1.5KW |

|

WZM-20L -4 |

4 |

10L |

15KG * 4 |

60 |

1.5KW |

The rotational speed of the ball mill is divided into two kinds of constant speed and speed regulation, and the corresponding rotational speed is chosen according to the properties of the ball milling raw materials. The ball mill can be used for dry grinding and wet grinding.

Experienced mining machinery manufacturer for nearly 15 years

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, electrostatic separator, vibrating screen, gold pan, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.