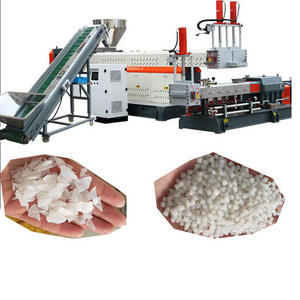

(2) Main motor : Imported " WEG "or " SIEMENS " Variable frequency motor

(The frequency converter will automatically change the frequency to reduce the frequency of the motor. The operating current will always run between 80%, 50%, and 30% of the rated power. This will greatly reduce the motor's operating current and achieve the effect of

saving electricity

).