- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.7mm-1.2mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HRF

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

6.5 kg

-

Feeding width:

-

100-600mm

-

Material Thickness:

-

0.8-2.0mm

-

Control system:

-

automatic

-

Main Power:

-

2-15kw

-

forming station:

-

18

-

work speed:

-

14m/min

-

Decoiling speed:

-

20m/min

-

Raw material:

-

PPGI

-

name:

-

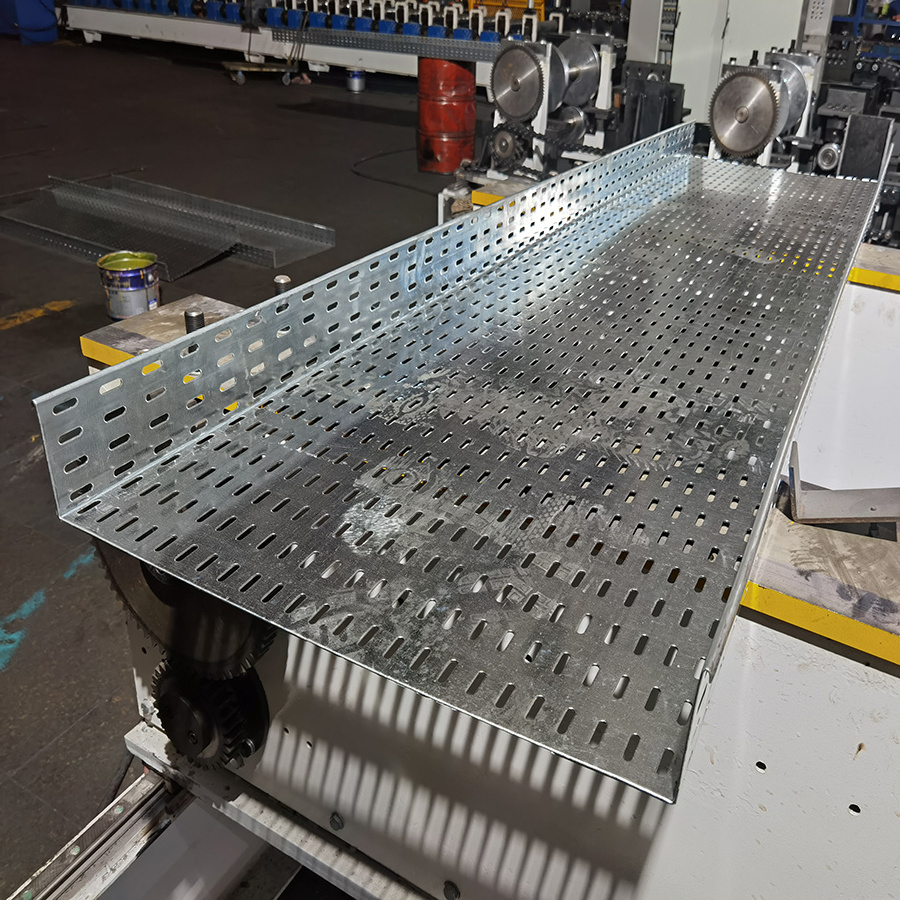

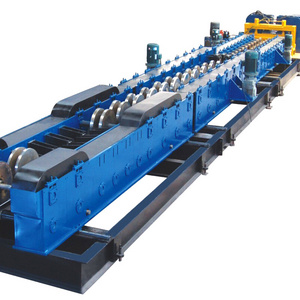

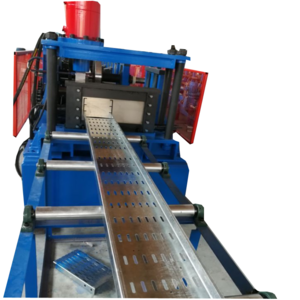

cable tray making machine cable tray roll forming machine

-

KEYWORDS:

-

cable tray machine

-

KEYWORDS1:

-

cable tray roll forming machine cold roll forming machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Glazed

-

Production Capacity:

-

10 m/min

-

Rolling thinckness:

-

0.7mm-1.2mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HRF

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

6.5 kg

-

Feeding width:

-

100-600mm

-

Material Thickness:

-

0.8-2.0mm

-

Control system:

-

automatic

-

Main Power:

-

2-15kw

-

forming station:

-

18

-

work speed:

-

14m/min

-

Decoiling speed:

-

20m/min

-

Raw material:

-

PPGI

-

name:

-

cable tray making machine cable tray roll forming machine

-

KEYWORDS:

-

cable tray machine

-

KEYWORDS1:

-

cable tray roll forming machine cold roll forming machine

Video display

Automatic

cable tray roll forming machine

Product parameter

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

5T hydraulic decoiler

|

1 set

|

1)Max 5T

2)Max coil:1000mm 3)Hydraulic inner expansion and motorized decoiling |

|

2

|

Guiding,feeding Leveling

|

1 set

|

1)2 pinch rolls and 7 rolls leveling

2)Rolls material:40Cr 3)Leveling speed:max 20m/min |

|

3

|

Servo-feeder system

|

|

1)Feeding speed:max 20m/min

2)Motor:1.8kw plus reducer |

|

4

|

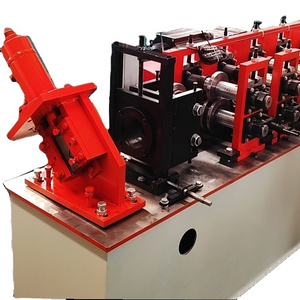

250T Punching press

|

1 set

|

1)Motor:15KW

2)Slide stroke:max 60 times /min |

|

5

|

100-600mm Width holes punching&cutting mould

|

1 set |

1)Mould material Cr12Mov

2)Combination mould to punch from 100mm to 600mm 3)Qty: 1 set 4)The punching heads will be controlled by air cylinders to punch rectangular holes and oval-shaped holes according to actual production size. |

|

6

|

Roll forming Machine

|

|

1)Cantilever type welded structure

2) 14 forming stations plus 4 vertical rolls 3)15KW motor made in China 4) Automatic size adjustment controlled by PLC 5) 1.2inch chain drive 6) Rolling speed:max 15m/min |

|

7

|

Hydraulic post-cutting system

|

1 set |

1) We adopt hydraulic post mould cutting

2) Cutting power:7.5kw 3) A set of cutting blade to cut from 100mm to 600mm |

|

8

|

Run-out table

|

2pcs

|

Steel frame with Rollers

|

|

9

|

Electric panel

|

1set

|

PLC control system made in Japan

|

|

10

|

Hydraulic system

|

1 set

|

Solenoid is from chinese famous brand

|

Scene application and quality inspection

Company profile

Established in 2009 Wuxi HRF Science & Technology Co.,Ltd lo

c

ated in Wuxi city,Jiangsu province is close to Shanghai international airport .we enjoy convenient transportation and advantageous location with which it can supply good business opportunities for the investors home and abroad.

We are specialized in designing,manufacturing the roll forming machines e.g cable tray forming machine,supermarket rack forming machine,expressway guardrail forming machine,grain silo forming machine,solar strut forming machine etc. These products are used widely in the field of steel structure ,building construction,supermarkets,factory warehouses,schools roofing,grain silos etc . In addition we also can manufacture all types of steel coils slitting machine,coils cut to length machines and tube mills

We are ready to establish the business relations with the overseas customers and we also believe" the opportunity here,here you are"

Our commitment is high-quality and in-time service , our goal is customer satisfaction.

Service Concept

Pragmatic and innovative service spirit

Modest and prudent service attitude

Professional and high-quality service team

A keen sense of service

Advantage

1. Convenient transportation: our factory is located in Wuxi city, closed to Shanghai City (two hours away), which provide short time and low-cost transportation expenses for you.

2. Full range of products: we can provide all kind of roll forming equipment which can be used to forming all kinds of shape as you required. The company can make non-standard products for client's requirement.

3. Specialized: There are specialized technical personnel and a list of experienced team responsible for quality assurance. Here are technical and skilled specialists, senior foreign trade staff and engineers.

4. Advanced and practical: For example, wall/ roof panel roll forming equipment solves the problem of roof leakage that conventional machine can not be able to handle with.

And also, the forming machines are national inspection-exempted products after external supervision and sampling inspection.

5. Professional and on time service:

As to pre-sale service, the company provides sample version for free. Well, that which party bears freight charges is consultative.

As to sales service, our company offers sales discounts and allowances to customers for the vulnerable parts. There is about 3-month delivery cycle from the beginning of orders. Foreign delivery cycle is almost the same as domestic one.

As to after-sale, there is one-year warranty period. During the warranty period, machine maintenance and repair will be provided for free.

What's more, our company can offer OEM business and provide simple for free for customers with our roll forming equipment and slitting line, cut to length line.

Authentication

Our exhibition

FAQ

1.Does one machine can only produce one size?

Not exactly, it depends on the machine.

2. Do you have after-sales support?

Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. How to visit your company?

We can pick you up from Shanghai or Hangzhou airport. Or railway station Shaoxing North.

4. What can you do if the machine is broken?

Our machine's warranty period is 12months. if the broken parts can't repair, we can send the new parts to replace the broken parts, but you need to pay the express cost by yourself. if after the warranty period, we can through negotiation for solving the problems, and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes, please tell us the destination port or address. we have rich experience in transport.

6. You are a trade company or factory?

We are a Manufacturer.

7. Why your price is higher than others?

As we persist on that each factory should put quality in the first place. We spend time and money on developing how to make machines much more automatic, accurate, and high quality. We can make sure that our machine could use more than 20 years without any problem.

8. Do you have overseas engineers?

Yes, we not only provide overseas engineers but also provide technical training.

9. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide. We are a professional sheet metal forming machine designer and manufacturer.

Hot Searches