wash the fresh cassava roots in clean water to remove mud, sand and other impurities. Note: The water source should be checked regularly to ensure it is not dirty or contaminated.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Automatic Grade:

-

Other

-

Voltage:

-

380v

-

Power:

-

2.2-75kw

-

Key Machines:

-

cassava peeling machine, cassava drying machine, cassava cutting machine

-

Product Type:

-

cassava chips

-

Product name:

-

Cassava Chips Drying Machine Dried Cassava Production Machine

-

Application:

-

Cassava processing plant

-

Machine Material:

-

Main Part Carbon/Stainless Steel

-

Certification:

-

ISO9001:2015

-

Advantage:

-

Low Consumption High Efficiency

-

Brand:

-

GOODWAY

-

After-sales Service Provide:

-

Field installation, commissioning and training

-

Warranty:

-

1-2 Year

-

After Warranty Service:

-

Online support

-

Package:

-

Standard Export Package

Quick Details

-

Machinery Capacity:

-

300-500kg/h

-

Brand Name:

-

GOODWAY

-

Dimension(L*W*H):

-

processing line

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Automatic Grade:

-

Other

-

Voltage:

-

380v

-

Power:

-

2.2-75kw

-

Key Machines:

-

cassava peeling machine, cassava drying machine, cassava cutting machine

-

Product Type:

-

cassava chips

-

Product name:

-

Cassava Chips Drying Machine Dried Cassava Production Machine

-

Application:

-

Cassava processing plant

-

Machine Material:

-

Main Part Carbon/Stainless Steel

-

Certification:

-

ISO9001:2015

-

Advantage:

-

Low Consumption High Efficiency

-

Brand:

-

GOODWAY

-

After-sales Service Provide:

-

Field installation, commissioning and training

-

Warranty:

-

1-2 Year

-

After Warranty Service:

-

Online support

-

Package:

-

Standard Export Package

300-500 Kg/h Cassava Chips Drying Machine Dried Cassava Production Machine

Goodway Tuberous Materials Processing Machine Solutions:

* Cassava Starch Processing Machine(Tapioca Starch Processing Machine);

* Potato Starch Making Machine;

* Sweet Potato Starch Making Machine;

* Canna Edulis Ker Starch Processing Machine;

* Cassava Flour(HQCF) Machine(High Quality Cassava Flour Processing Machine);

* Cassava Garri Processing Machinery(Gari Processing Machine);

* Cassava Fufu Processing Machine(Fufu Machine);

* Cassava Chips Making Machine(Cassava Cutting Production Line);

* Yam Flour Processing Machine(Amala Yam Flour Making Machine);

* Potato Starch Making Machine;

* Sweet Potato Starch Making Machine;

* Canna Edulis Ker Starch Processing Machine;

* Cassava Flour(HQCF) Machine(High Quality Cassava Flour Processing Machine);

* Cassava Garri Processing Machinery(Gari Processing Machine);

* Cassava Fufu Processing Machine(Fufu Machine);

* Cassava Chips Making Machine(Cassava Cutting Production Line);

* Yam Flour Processing Machine(Amala Yam Flour Making Machine);

* Starch Vermicelli Glass Noodles Processing Line.

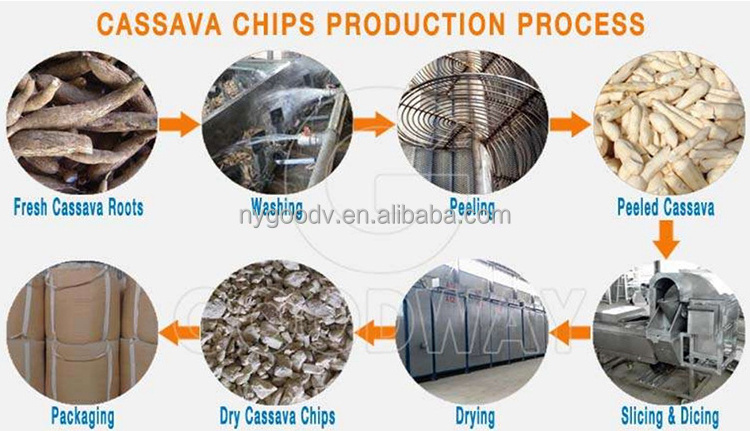

Product Description

The production of cassava chips comprises the machines such as cassava washing machine, peeling machine, chipping machine, cassava chips drying machine - belt type dryer and packaging machine.

We have provided below a brief description on the main steps of the cassava chips production process.

Details Images

1. Cassava washing machine:

2. Cassava peeling machine:

and peel the cassava roots to remove the outer brown skin and partial inner thick cream layer, also avoid over damaging of raw materials.

3. Cassava chipping machine(cassava chipper):

cut the peeled cassava roots to produce thinner and more uniform slices than chipping by hand.

4. Cassava chips drying machine(belt type dryer):

effectively dry the cassava chips or slices to low moisture content by principle of heat transfer exchange.

Hot Searches