- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*900*2200mm

-

Weight:

-

600 KG

-

Certification:

-

CE

-

Filling speed:

-

20-100 times / min

-

Material:

-

Stainless Steel

-

Packaging accuracy:

-

±1%

-

Filling capacity:

-

200-550ml

-

Air pressure:

-

0.6-0.8Mpa

-

Applied bottle range:

-

Round Tin Can

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Wood, body lotion filling machine

-

Filling Material:

-

Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

99

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*900*2200mm

-

Weight:

-

600 KG

-

Certification:

-

CE

-

Filling speed:

-

20-100 times / min

-

Material:

-

Stainless Steel

-

Packaging accuracy:

-

±1%

-

Filling capacity:

-

200-550ml

-

Air pressure:

-

0.6-0.8Mpa

-

Applied bottle range:

-

Round Tin Can

-

After Warranty Service:

-

Video technical support

Automatic aerosol tin can spraying filling line use

booster pump, which will convert the mixed liquid and gas to totally liquid. Then put it into add pump to storage, When the gas charging, add the pump suction the liquid from the quantitative tank. And then Quantitative cylinder piston work, gas charging finished. As the inflated gas has been completely transformed into liquid, so it can ensure the accuracy of inflation. The machine uses Quantitative SS316L stainless steel piston pump: corrosion, durable, quantitative criteria. When charging different specifications, it will adjust the charging quantity. There is a graduated scale at the piston pump, simply twist the hand wheel to adjust the gas charging quantity.

|

Product

|

Automatic aerosol tin can spraying filling line

|

|

Output

|

1500-6000BPH (Customized)

|

|

Filling Volume

|

200-550ml (can be customized)

|

|

Control

|

PLC and Touch Screen

|

|

Driving Motor

|

Servo Motor

|

|

Filling Precision

|

±1%

|

|

Valve Feeding Precision

|

±1%

|

|

Air Consumption

|

0.6-0.8Mpa

|

|

Power

|

1.0KW

|

|

Machine Frame Material

|

SS304

|

|

Power Supply

|

220/380V, 50/60Hz

|

Bottle Feeding Table

Variable speed bottle feeding table is the basic feeding system of aerosol spray bottle filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to the conveyor, the machine will be able to work with different size bottle.

Liquid Filling Machine

This machine adopts position pump, which is suitable for different kinds liquids, with high filling speed and high filling precision. The pump uses quick-fit removal structure: easy cleaning and disinfection. The filling nozzles adopt anti-drip and anti-drawing filling device. The machine adopts PLC and human-computer touch screen control

system.

system.

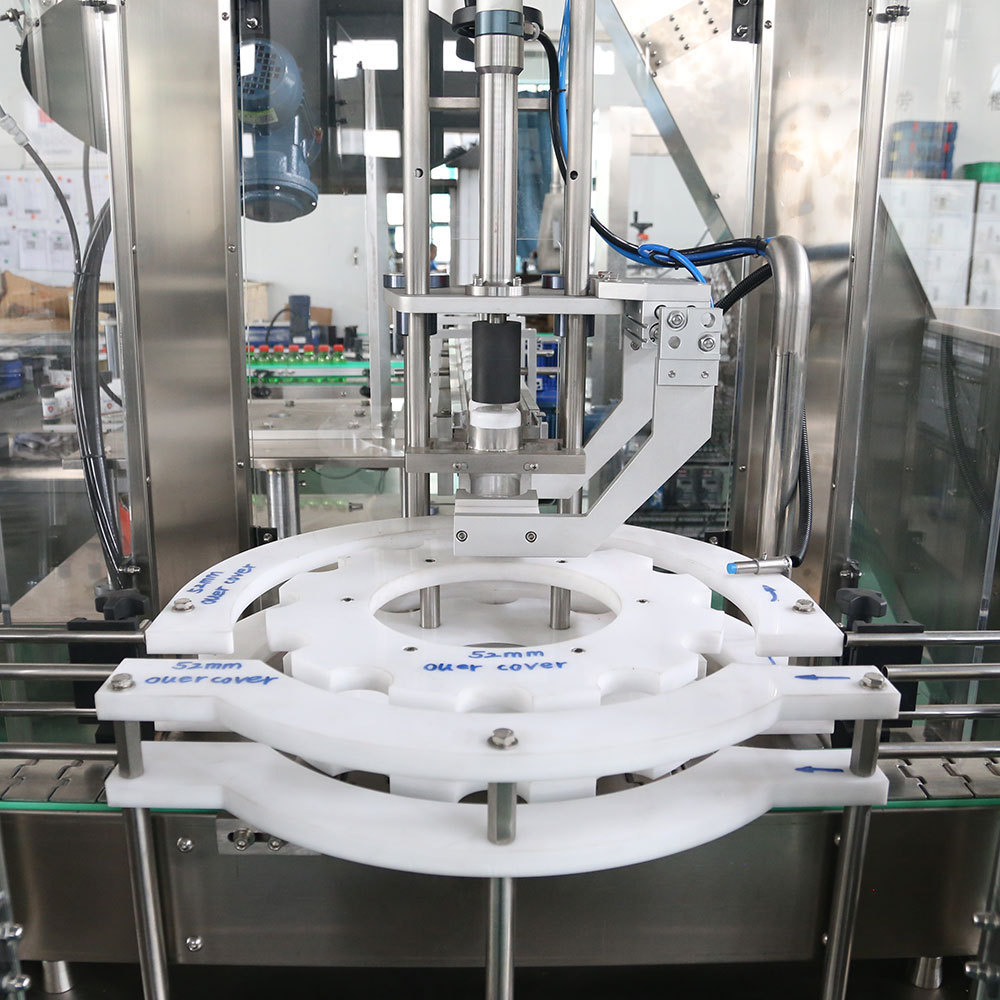

Spray Valve feeding machine

This valve putting part worked with stable speed and high efficiency. The machine adopts PLC and human-computer touch screen control system. The valve sorter and feeding parts can be easy to change for the different size.

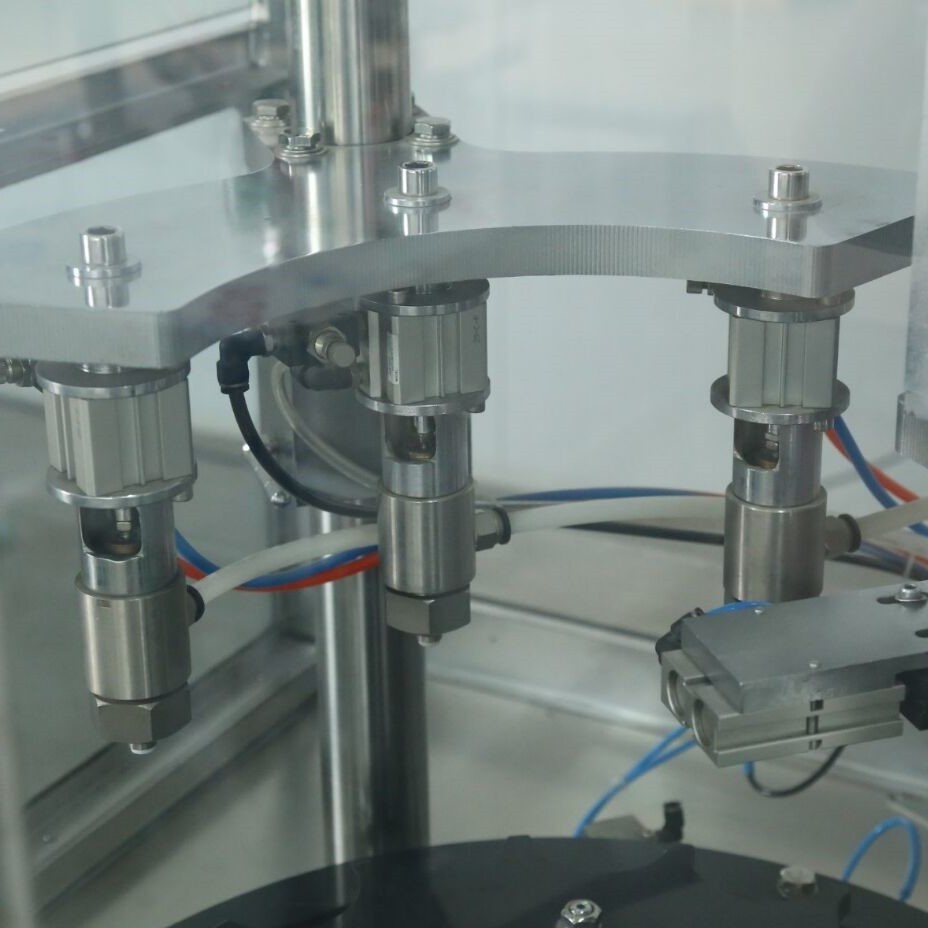

Spray Valve Sealing Machine

The sealing head is specially designed according to valve. When sealing the bottle, first step press valve to position it, then sealing claw will seal the bottle. The air proof circle inside the valve will tightly linked to the bottle, so it is beautiful without leakage.

Spray Head Pressing Machine

The vibrating cap feeder will arrange the spray heads automatically, sending the caps to the production line from the pipe under the air power. It can save labors and increase productivity.

Electric Cabinet and Touch Screen

Hot Searches