- Product Details

- {{item.text}}

Quick Details

-

Application:

-

landfill project, artificial lake, landfill

-

Design Style:

-

geosynthetic clay line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Schiebel

-

Model Number:

-

GCL-NP6000

-

Weight:

-

≥6000g/m2

-

Product size:

-

5.8mx30m

-

Usage:

-

Earthwork Apllication

-

Thickness:

-

≥6mm

-

Function:

-

seepage-proofing

-

Product name:

-

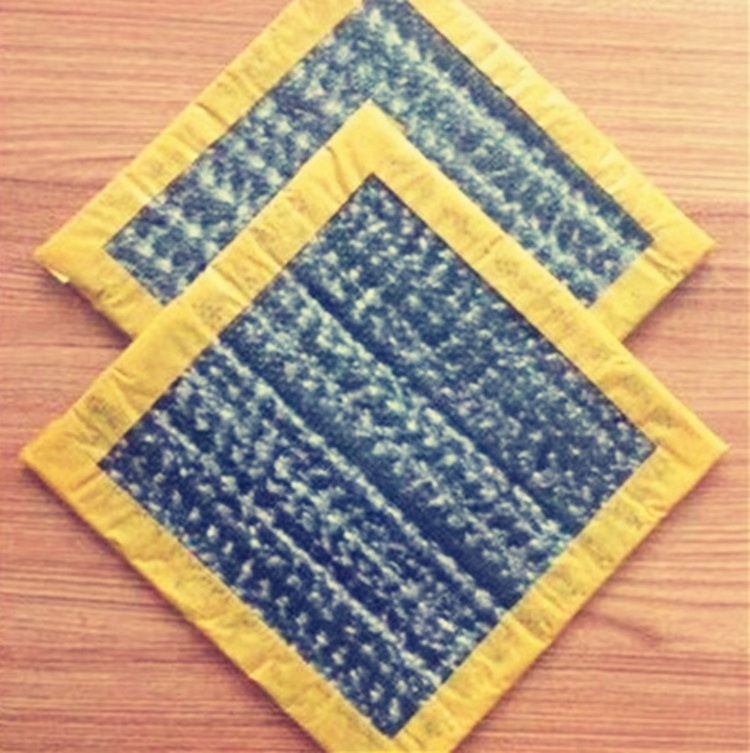

high quality bentonite geosynthetic clay layer waterproof GCL liner

-

Keyword:

-

bentonite geosynthetic clay layer

-

Certificate:

-

ISO9001/ ISO14001/ OHSAS18001

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support, Onsite Training, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

NONE, Others

-

Application:

-

landfill project, artificial lake, landfill

-

Design Style:

-

geosynthetic clay line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Schiebel

-

Model Number:

-

GCL-NP6000

-

Weight:

-

≥6000g/m2

-

Product size:

-

5.8mx30m

-

Usage:

-

Earthwork Apllication

-

Thickness:

-

≥6mm

-

Function:

-

seepage-proofing

-

Product name:

-

high quality bentonite geosynthetic clay layer waterproof GCL liner

-

Keyword:

-

bentonite geosynthetic clay layer

-

Certificate:

-

ISO9001/ ISO14001/ OHSAS18001

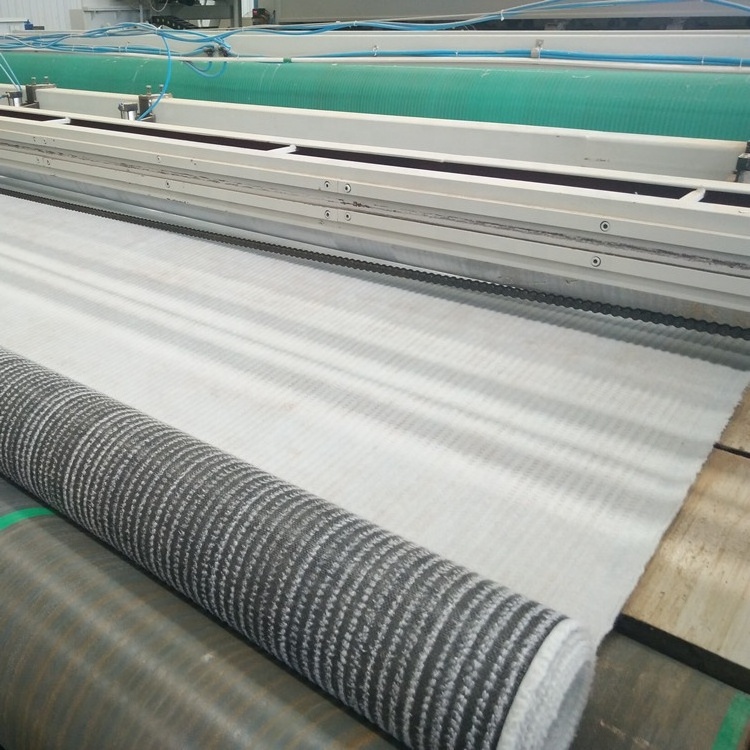

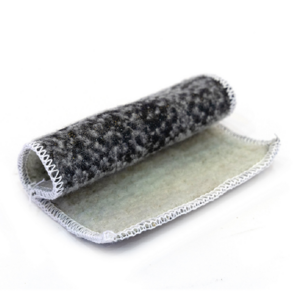

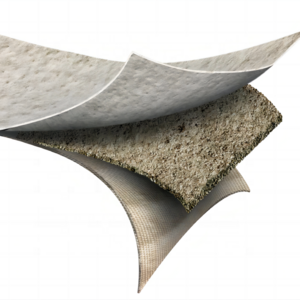

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives.

Due to environmental laws, any seepage from landfills must be collected and properly disposed off, otherwise contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs. A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength.

1. The storage and transportation of bentonite composite waterproof mat (GCL) should be waterproof, moisture-proof and strong against sunlight. When storing, the ground should be padded by overhead method, and the bentonite composite waterproof pad (GCL) shipped to the site should be used up on the same day.

2. When carrying out the next process or adjacent construction, the bentonite composite waterproof pad (GCL) of the completed process should be properly protected and there should be no human damage.

3, should try to avoid wearing spike shoes, high heels on the bentonite composite waterproof pad (GCL) stepping on;

Machinery such as vehicles shall not crush bentonite composite waterproof mat (GCL).

4. In the construction of GM/GCL composite liner, the completed GCL should complete the construction of HDPE film or lay a 300mm thick clay protective layer on the same day. The construction of HDPE film or clay protective layer cannot be completed on the same day, and the GCL should be covered. In order to prevent rain and snow, GCL will be hydrated first and strong sunlight will be exposed to GCL