- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.05+

-

Length:

-

customizable

-

Working Temperature:

-

1250

-

Shrinkage (1800 ℉, 3h):

-

4-

-

Thermal Conductivity:

-

0.15-0.28

-

Model Number:

-

ENTO-1430Blanket

-

Brand Name:

-

EPOWOOL

-

Place of Origin:

-

Jiangsu, China

-

Density:

-

128kg/m3

-

GB/T17911.8(W/mK):

-

0.15(at average 600°C) 0.20(at average 800°C) 0.28(at average 1000°C)

-

Packaging:

-

Cardboard box or woven bag

-

SIZE:

-

14400*610*6mm/roll

-

Application of ceramic fiber board:

-

Industrial Furnace Refractory

-

Certificate:

-

ISO

Quick Details

-

Thickness:

-

6mm

-

Width:

-

customizable

-

Chemical Composition:

-

Al2O3+SiO2+ZrO2

-

Ultimate Strength (≥ MPa):

-

0.05+

-

Length:

-

customizable

-

Working Temperature:

-

1250

-

Shrinkage (1800 ℉, 3h):

-

4-

-

Thermal Conductivity:

-

0.15-0.28

-

Model Number:

-

ENTO-1430Blanket

-

Brand Name:

-

EPOWOOL

-

Place of Origin:

-

Jiangsu, China

-

Density:

-

128kg/m3

-

GB/T17911.8(W/mK):

-

0.15(at average 600°C) 0.20(at average 800°C) 0.28(at average 1000°C)

-

Packaging:

-

Cardboard box or woven bag

-

SIZE:

-

14400*610*6mm/roll

-

Application of ceramic fiber board:

-

Industrial Furnace Refractory

-

Certificate:

-

ISO

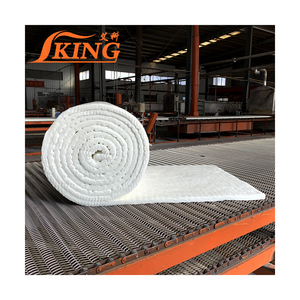

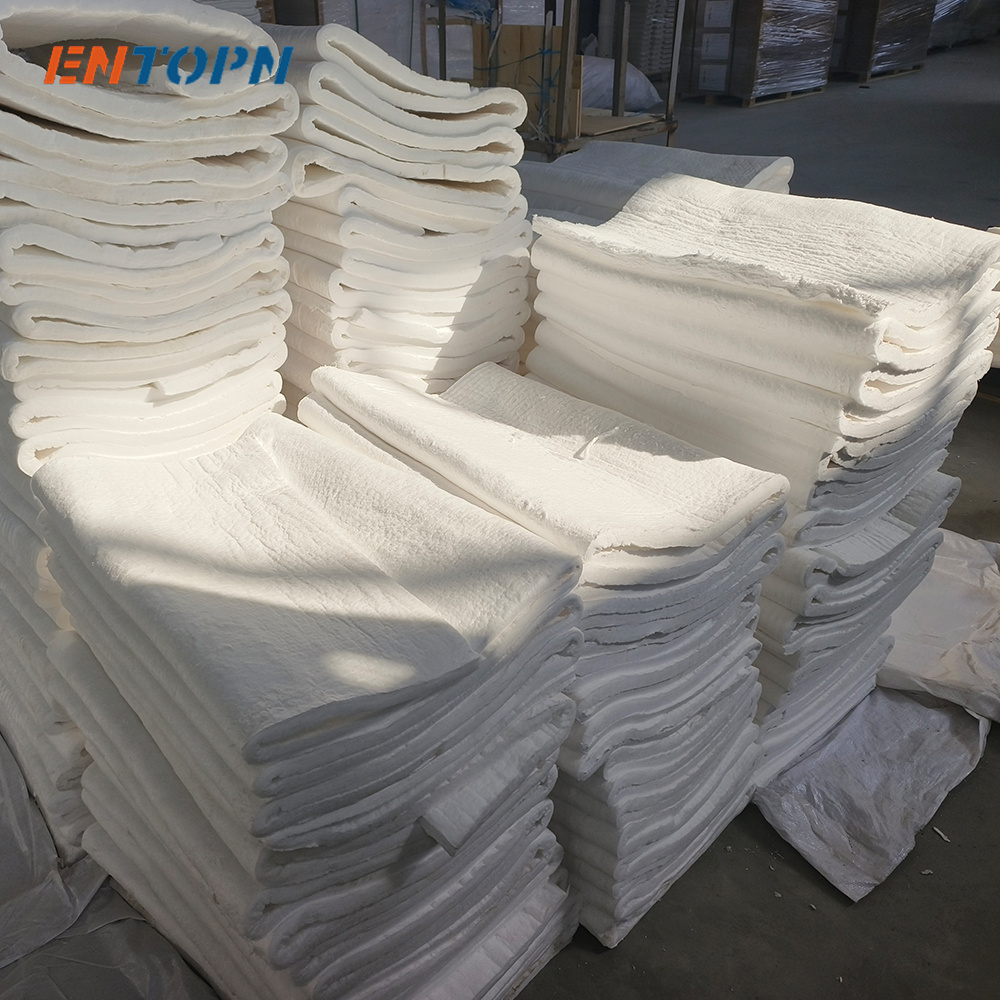

EPOWOOL ® Ceramic Fiber Blanket

EPOWOOL® ceramic fiber blanket is a strong, light weight, flexible blanket made from long ceramic fibers. EPOWOOL® ceramic fiber blanket is manufactured by cross locking alumina-silicate fibers through a unique forming process to produce a blanket with unexcelled handling strength. This material is a highly efficient insulator having low heat storage capacity and complete resistance to damage from thermal shock.

|

|

|

|

1000 Blanket

|

1260 Blanket

|

1400 Blanket

|

1430 Blanket

|

||||

|

Working Temperature

|

|

°C

|

800

|

1000

|

1200

|

1250

|

||||

|

Density

|

|

kg/m3

|

128

|

128

|

128

|

128

|

||||

|

Tensile Strength

|

|

Mpa

|

≥0.05

|

≥0.05

|

≥0.05

|

≥0.05

|

||||

|

Heat Linear Shrinkage

|

|

%

|

≤4(at 1000°C*24h )

|

≤4(at 1260°C*24h )

|

≤4(at 1400°C*24h )

|

≤4(at 1430°C*24h )

|

||||

|

pyroconductivity(GB/T17911.8)

|

|

W/mK

|

0.15(at average 600°C)

0.20(at average 800°C) 0.28(at average 1000°C) |

|

|

|

||||

|

Chemistry

|

Al2O3

|

%

|

36-39

|

40-44

|

43-45

|

34-37

|

||||

|

|

Al2O3+SiO2

|

%

|

≥95

|

≥98

|

≥90

|

≥99

(Al2O3+SiO2+ ZrO2) |

||||

|

|

ZrO2

|

%

|

-

|

-

|

5-8

|

15-17

|

||||

|

Dimension

|

|

mm

|

3600/7200*610*25/50

|

|

|

|

||||

|

Packaging

|

|

-

|

Cardboard box or woven bag

|

|

|

|

||||

* The data shown are test results obtained under standard procedures and are subject to change

* To confirm that the product meets your application requirements and other parameters, please consult the engineering department.

Typical Applications

• Furnace, Kiln and Boiler insulation.

• Furnace door lining and fire seals.

• Flexible high temperature pipe insulation.

• Domestic cooker insulation.

• High temperature gasketing.

EPOWOOL® ceramic fiber blanket offers below advantages

• Excellent thermal and physical stability up to 1260ºC

• Thermal shock resistance

• Light weight

• Resiliency

• Excellent corrosion resistance

• Excellent sound absorption

Ento High Temperature Materials (Jiangsu) Co., Ltd.

Our main products include: ceramic fiber board, ceramic fiber shaped parts, ceramic fiber paper, ceramic fiber cotton, ceramic fiber blanket, ceramic fiber module, high temperature binder and coating, nano insulation materials and other refractory insulation products; At the same time, it provides a perfect energy-saving application scheme. Product application temperature covers 800 degrees Celsius to 1800 degrees Celsius.

After years of accumulation, the enterprise has established a stable production management system, reliable quality system and perfect sales channels. Ceramic fiber series products because of its low heat capacity, low thermal conductivity, high refractoriness and other advantages, many users as the preferred energy-saving materials, widely used in petroleum, chemical, electric power, steel, cement, glass, ceramics and other industries.

Products are sold all over the country and exported to the United States, Japan, Vietnam, Turkey and many other countries and regions. We have made efforts for many enterprises in energy saving, light structure of furnace body and improvement of operating environment.

1.You are a manufacture or a trading company ?

We are a manufacturer founded in 2002, located in jiangsu China. We not only provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

2.What kind of product can you offer ?

Our company can offer all kind of refractory insulation materials. For example: Ceramic Fiber Products, Soluble Fiber board, Hydrophobic Fiber board, Microporous Board, monolithic Module, Silicate Products, High-Temperature Binder Etc.

3.Can you provide free samples ?

Free samples are available !

4.What is your MOQ?

We don't have particular MOQ, we can accept any order for any different projects.Price depends on quantity.

5.Can we have a visit to your factory ?

Yes! Of course,welcome to visit our factory at anytime on site or online !

If you have any questions or you cannot find the products you wa

nt, please do not hesitate to contact us ,we will try our best to satisfy your requirements.

Hot Searches