- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v/440v

-

Dimension(L*W*H):

-

1400*1350*1500mm

-

Power (kW):

-

15kw

-

Weight (KG):

-

500 KG

-

Name:

-

EPS Foam Hot Melting Machine

-

Brand:

-

Lianding

-

Motor:

-

Siemens

-

Raw material:

-

EPS Foam

-

Service condition:

-

customized

-

Operation staff:

-

2-3people

-

Function:

-

eps foam block making machine

-

Capacity:

-

100-400kg/h

-

Finished products:

-

EPS Blocks

-

Quality control:

-

testing machine in our factory before delivery

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianding

-

Machine Type:

-

foam melting recycling

-

Voltage:

-

220v/380v/440v

-

Dimension(L*W*H):

-

1400*1350*1500mm

-

Power (kW):

-

15kw

-

Weight (KG):

-

500 KG

-

Name:

-

EPS Foam Hot Melting Machine

-

Brand:

-

Lianding

-

Motor:

-

Siemens

-

Raw material:

-

EPS Foam

-

Service condition:

-

customized

-

Operation staff:

-

2-3people

-

Function:

-

eps foam block making machine

-

Capacity:

-

100-400kg/h

-

Finished products:

-

EPS Blocks

-

Quality control:

-

testing machine in our factory before delivery

Product description

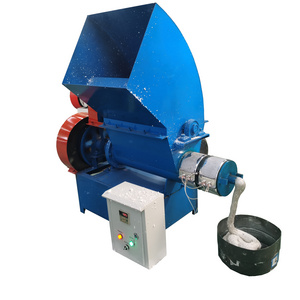

Polystyrene EPS Foam hot Melting Recycling Machine Plastic Melter Densifier

Product Description:

Our EPS hot melting recycling machine adopts manual feeding, the material will be crushed by the four shaft blades and conveyed to the barrel of the main machine through the screen. This screw of the main machine can convey the heat the material to melt condition, then and air jam blade cut them to pieces for easy storage and transportation.

Technical Parameters:

Suitable Products:

It is suitable for EPP EPE XPS PUR EVA EPS plastic foam and polystyrene foam, such as foam box, EPS foam board, EPS foam fast food box, etc.

Main features:

1.The whole machine structure and the axis and the blades are carbon steel.

2.Twin shaft crushing blades. This machine adopts manual feeding, the material will be crushed by the twin shaft blades and conveyed to the barrel of the main machine through the screen.

2.The screw of the main machine can convey and heat the material to melt condition, then extrude them and hydraulic blade cut them to pieces for easy storage and transportation.

3.The shapes of the products can be designed according to customers' requirements.

1.The whole machine structure and the axis and the blades are carbon steel.

2.Twin shaft crushing blades. This machine adopts manual feeding, the material will be crushed by the twin shaft blades and conveyed to the barrel of the main machine through the screen.

2.The screw of the main machine can convey and heat the material to melt condition, then extrude them and hydraulic blade cut them to pieces for easy storage and transportation.

3.The shapes of the products can be designed according to customers' requirements.

More pictures of machines:

Our Service

Our advantages

Hot Searches