- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

440/380V

-

Power:

-

350KW Approximately

-

Dimension(L*W*H):

-

28m*2.2m*3.8m, 28m*2.2m*3.8m

-

Weight:

-

85000 kg

-

Marketing Type:

-

New Product 2022

-

PLC brand:

-

GIPEN SCHNEIDER, DELTA, KEYENCE, OMRON, MITSUBISHI

-

Raw material:

-

Wood Pulp/PE Film/Nonwoven/SAP

-

After-sales Service Provided:

-

Video technical support, Field installation

-

Function:

-

Embossing Folding Counting Cutting

-

Application:

-

Baby Diaper With Belt

-

Product size:

-

S/M/L/XL

-

After-sales Service:

-

video techinician/technican support

-

Raw materials:

-

Wood Pulp/PE Film/Nonwoven/SAP

-

Operator:

-

8-10

Quick Details

-

Production Capacity:

-

600-800pcs/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

BY

-

Voltage:

-

440/380V

-

Power:

-

350KW Approximately

-

Dimension(L*W*H):

-

28m*2.2m*3.8m, 28m*2.2m*3.8m

-

Weight:

-

85000 kg

-

Marketing Type:

-

New Product 2022

-

PLC brand:

-

GIPEN SCHNEIDER, DELTA, KEYENCE, OMRON, MITSUBISHI

-

Raw material:

-

Wood Pulp/PE Film/Nonwoven/SAP

-

After-sales Service Provided:

-

Video technical support, Field installation

-

Function:

-

Embossing Folding Counting Cutting

-

Application:

-

Baby Diaper With Belt

-

Product size:

-

S/M/L/XL

-

After-sales Service:

-

video techinician/technican support

-

Raw materials:

-

Wood Pulp/PE Film/Nonwoven/SAP

-

Operator:

-

8-10

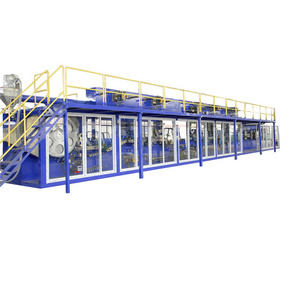

Main parameters

Machined material: Steel

Machine size(m):28m*2.2m*3.8m(based on the product provided by client)

Machine w eight : 85 Tons approximately

Design speed:600-800pcs per minute.

Efficiency: ≥ 85%

Machine capacity:300-500KW approximately

Machine function:Use for producing baby diaper

The full servo baby diaper pants production line features servo motors, a touch screen, a PlC control system, and a human-machine interface display to make the operation clearer and more convenient, as well as a high degree of automation to make the machine more user-friendly. Automatic material arrangements and delivery mechanisms are used to facilitate linked production with automated production lines, which can significantly reduce labor costs. The photoelectric automatic detection and tracking system was used to conserve packing materials to the utmost. The change of gauge does not require a change of mold but may be affected by the adjustment. It has automated conveyor belts that easily connect to automated production lines, saving labor costs. High automation, high specialization, high efficiency, but less hassle. Different sizes can be easily handled thanks to a fast and simple switching facility. In addition, the production line can run continuously without downtime, further improving efficiency.

Equipped with an advanced photoelectric detection system, the auto-stop is material-free and enhances efficiency. The full servo baby diaper pants production line is equipped with elastic waistline, frontal tape, side tape,solid-protecting,leg-elastic structures, with a rolling rubber band, active feed, servo control, rubber band tightness can be set on the touch screen, zero drop speed receiving device, material intermediate joint detection, automatic picking waste, material detection, automatic alarm and stop of material cut-off are equipped with automatic correction device, and the front waist paste transmission is controlled by servo motor, electric eye alignment by marked lines, short cutting using a scraper, online scraping glue compound.

We will provide you with a one-stop shop for pre-sales, sales, and after-sales. From the design and production of the machine to the meticulous delivery of the machine. We will produce your machine according to your requirements, provide overseas installation and technical personnel training, speed up the use of the machines, provide factory production efficiency and increase factory profits.