- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Sandwich Coldroom Panel

-

Steel thickness:

-

0.4-0.7mm

-

PU thickness:

-

50-200mm

-

Width:

-

1000mm

-

Length:

-

1-11.8m

-

Color:

-

Any Ral Color

-

Core material:

-

Hard Polyurethane Foam

-

Water absorption:

-

<0.30(kg/m3)

-

PU density:

-

40-42KG/m3

-

Usage:

-

prefab houses, warehouse, factory, shop, office, etc.

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Warehouse

-

Design Style:

-

Modern

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Sandwich Coldroom Panel

-

Steel thickness:

-

0.4-0.7mm

-

PU thickness:

-

50-200mm

-

Width:

-

1000mm

-

Length:

-

1-11.8m

-

Color:

-

Any Ral Color

-

Core material:

-

Hard Polyurethane Foam

-

Water absorption:

-

<0.30(kg/m3)

-

PU density:

-

40-42KG/m3

-

Usage:

-

prefab houses, warehouse, factory, shop, office, etc.

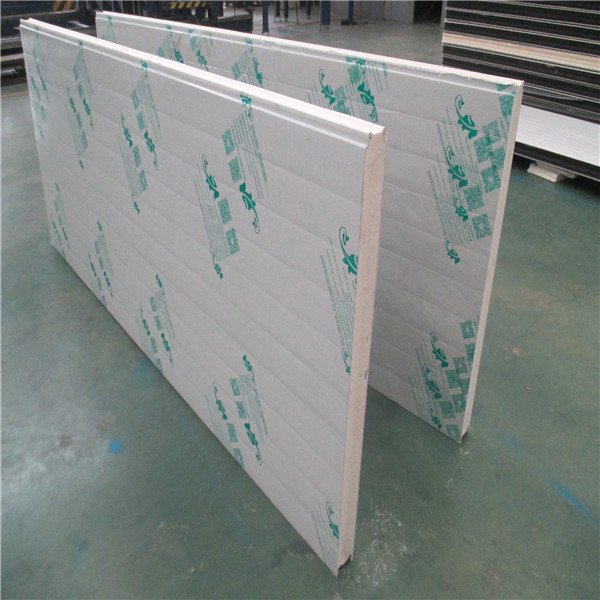

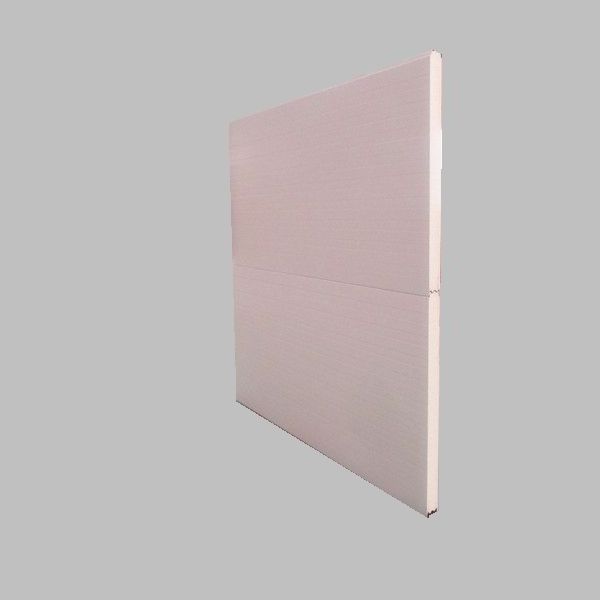

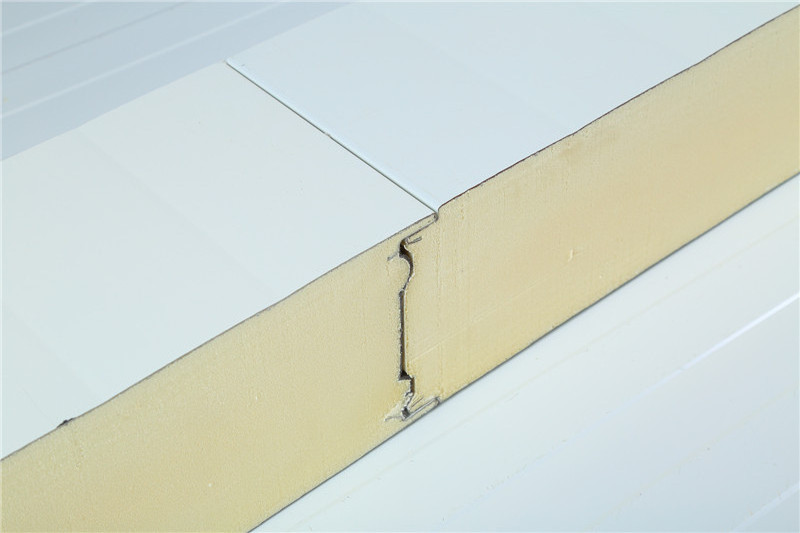

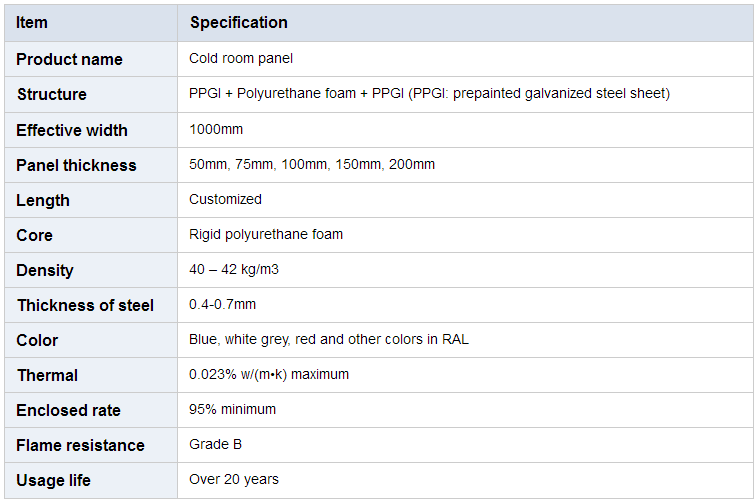

The polyurethane cold room panel is composed of two galvanized stee sheets and rigid polyurethane foam in the middle. Because the polyurethane cold room panel has several outstanding advantages, such as thermal insulation, waterproof, light weight and fast installation, It has been widely used as the building material of cold storages, cool rooms, clean rooms, free-dust workshops and exterior walls in cold places.

At present, BRD polyurethane cold room panel has five different thickness: 50mm, 75mm, 100mm, 150mm, 200mm.

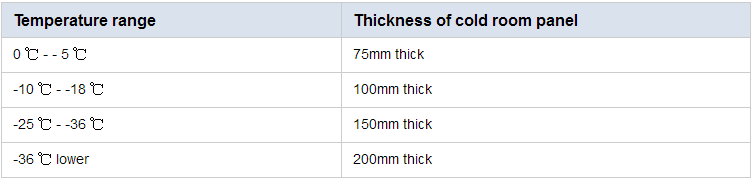

Cold room panels with different thickness are applied for different temperature requirements.

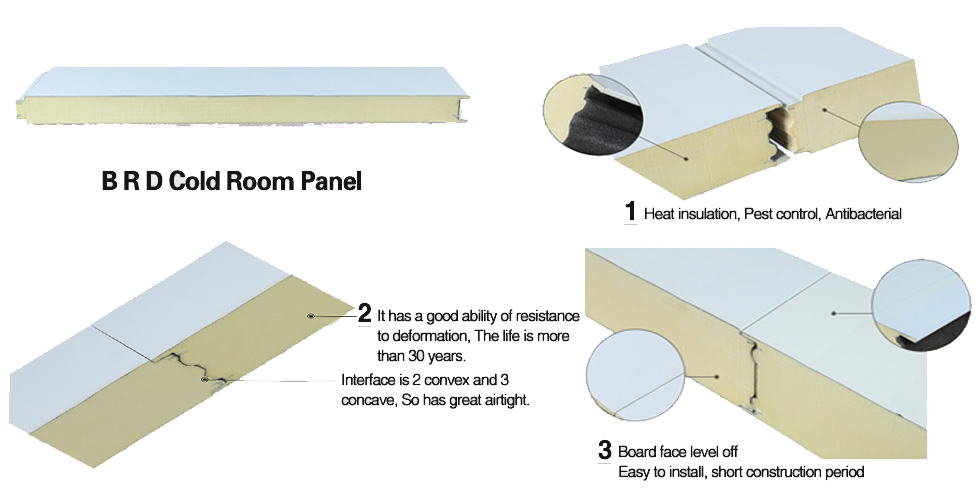

1, Good imported raw material: USA Huntsman.

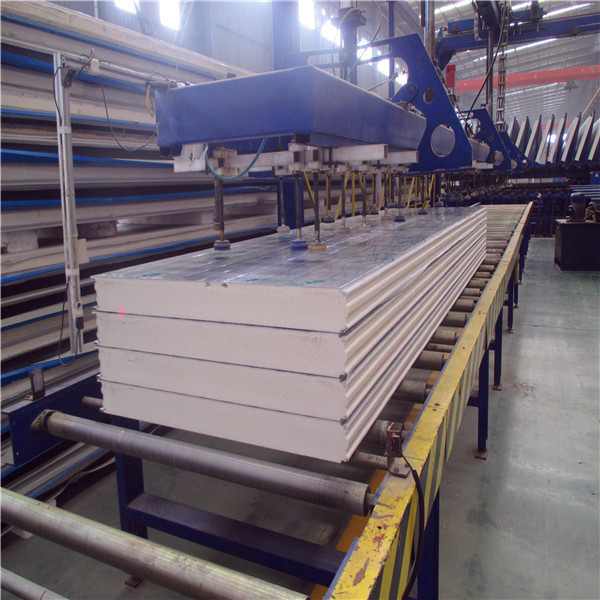

2, Evenly foamed polyurethane: totally automatic production line.

3, Rather low air permeability: black seal strip gives an extra enhancement.

4, Strong adhesion: seperation will never happens on steel sheets and polyurethane foam.

Cold room panel is a new building material for cold storages and other buildings in cold places. It performs outstanding in aspects of thermal insulation and the waterproof, so it is widely accepted as a wonderful insulation building material. It is composed of two galvanized steel sheets and rigid polyurethane foam in the middle.

The sales net is targeted at those countries and places where are eager for sandwich panels. Till now, BRD sandwich panels have been exported to over 21 countries and places and more and more customers have made twice or third order, which proves BRD is worth of your reliance.