- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120w

-

Dimension(L*W*H):

-

3000*840*2250

-

Weight:

-

700 KG

-

Product name:

-

Wiped film distillation

-

Model:

-

FMD-series

-

Effective evaporation area(m2):

-

0.1-5

-

Condensing area(m2):

-

0.17-8

-

Feeding speed(L/H):

-

60-180

-

Rotate speed(r/min):

-

30-350

-

Stainless steel material:

-

304/316

-

Operating Temperature(℃):

-

Within 350℃

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanphan

-

Voltage:

-

220V/50-60HZ, 220V/50Hz or customize

-

Power:

-

120w

-

Dimension(L*W*H):

-

3000*840*2250

-

Weight:

-

700 KG

-

Product name:

-

Wiped film distillation

-

Model:

-

FMD-series

-

Effective evaporation area(m2):

-

0.1-5

-

Condensing area(m2):

-

0.17-8

-

Feeding speed(L/H):

-

60-180

-

Rotate speed(r/min):

-

30-350

-

Stainless steel material:

-

304/316

-

Operating Temperature(℃):

-

Within 350℃

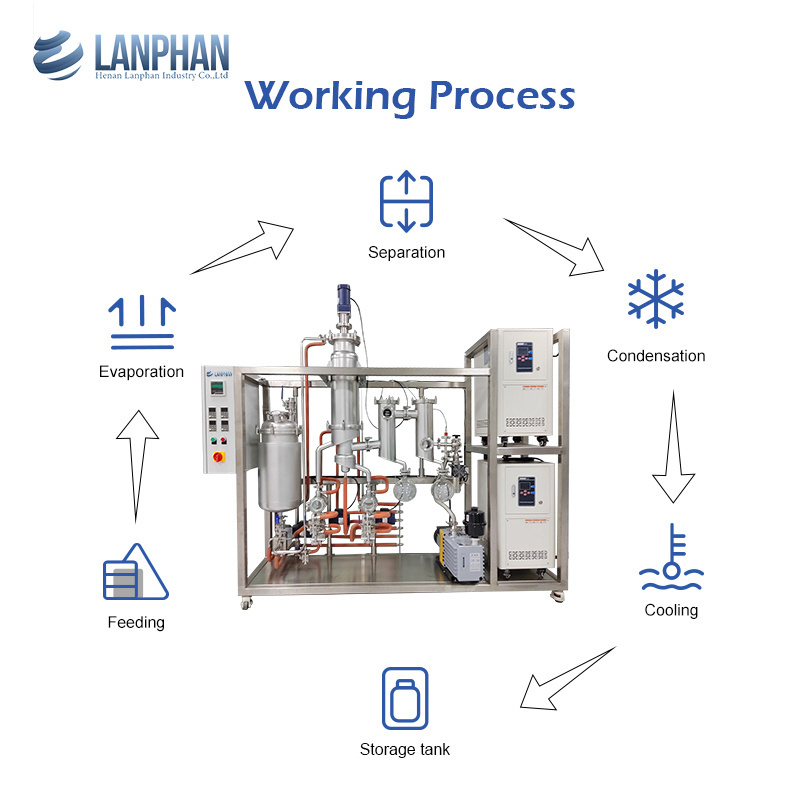

Molecular distillation is a special liquid-liquid separation technology, which is different from the traditional distillation based on the separation principle of material boiling point difference, but based on the difference in the mean free path of molecular motion of each material in the mixture to achieve separation. According to the principle of the mean free path of molecular motion.

| Model | FMD-0.1SS | FMD-0.15SS | FMD-0.25SS | FMD-0.35SS | FMD-0.5SS | FMD-1SS | FMD-1.5SS | FMD-2SS | FMD-3SS | FMD-5SS |

| Effective evaporation area(m2) | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1 | 1.5 | 2 | 3 | 5 |

| Condensing area(m2) | 0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 | 8 |

| Rotate speed(r/min) | 30-350 | |||||||||

| Stainless steel material | 304/316 | |||||||||

| Feeding method | Gear pump automatic continuous feeding | |||||||||

| Discharge method | Gear pump automatic continuous discharge | |||||||||

| Operating Temperature(℃) | Within 350℃ | |||||||||

| Voltage | 220V/60Hz | |||||||||

| Other voltages can be customized | ||||||||||

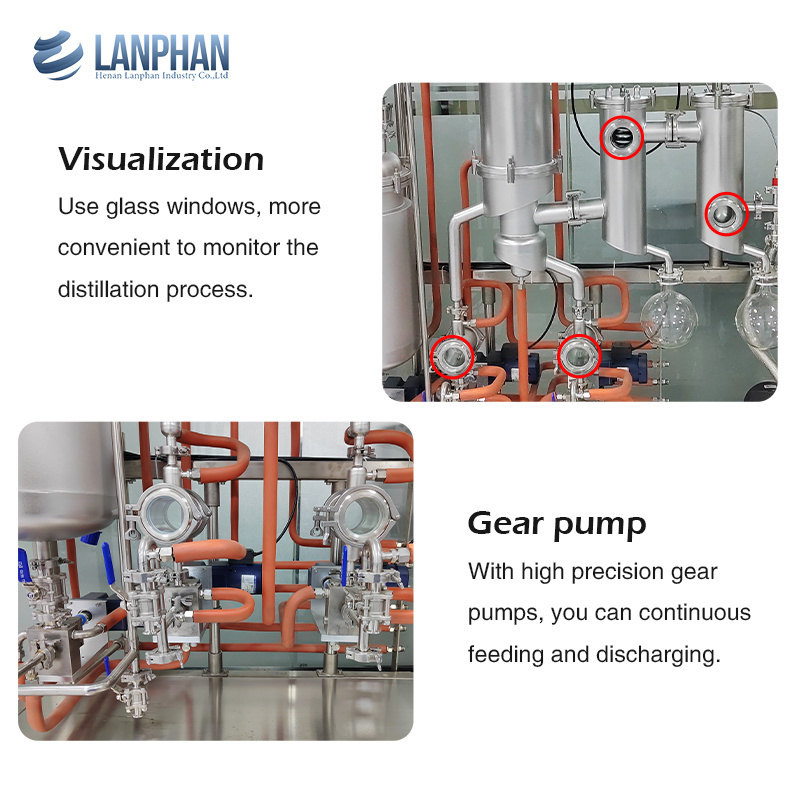

1. The gear pump is used for continuous feeding.

2. The gear pump is used for continuous discharg ing.

3. Jacketed conveying pipeline has good heat preservation effect.

4. The cooling system adopts serpentine condenser and cold trap.

5. The evaporator is made of high-quality stainless steel, which has fast heat transfer, high efficiency and durability.

Advantages:

1. The heating time of the material is short. 2. Low evaporation temperature.

3. High evaporation efficiency. 4. Continuous feeding and discharging.

5. Made of corrosion-resistant 316 stainless steel. 6. The heat transfer rate is fast.

Functions:

1. Thermal separation of heat-sensitive compounds.

2. Purification of organic synthetic substances .

3. Purification of active ingredients in biological extracts.

4. Recycling of industrial waste.

5. Removal of toxic substances in the food industry.

6. Decolorization and odor removal of organic compounds.

7. Thorough removal of residual solvents in the compound.