- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

1600 r.p.m

-

Max. Weight of Workpiece(kg):

-

200

-

Spindle Bore(mm):

-

90

-

Width of bed (mm):

-

390 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

1370

-

Travel (X Axis)(mm):

-

1000 mm

-

Travel (Z Axis)(mm):

-

250 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2950X1700X1800

-

Brand Name:

-

UnionTech

-

Model Number:

-

UT6150

-

Voltage:

-

220v/380v

-

Weight (KG):

-

2500

-

Marketing Type:

-

Hot Product

-

Brand:

-

UnionTech

-

Model:

-

UT6150

-

Controller:

-

FANUC/GSK/SIENMENS/SYNTEC

-

Turret Type:

-

4/6/8/12 Station

-

Usage:

-

Turning Milling Tapping Drilling Functions

-

CNC or Not:

-

CNC Lathe Machine

-

Precision:

-

0.008mm

-

Keyword:

-

Cnc Metal Lathe Machine

-

Product type:

-

Cnc Horizontal Turning Lathe Machine

-

Chuck:

-

Pneumatic Chuck

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

1370

-

Year:

-

custom made

-

Max. Spindle Speed (r.p.m):

-

1600 r.p.m

-

Max. Weight of Workpiece(kg):

-

200

-

Spindle Bore(mm):

-

90

-

Width of bed (mm):

-

390 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

1370

-

Travel (X Axis)(mm):

-

1000 mm

-

Travel (Z Axis)(mm):

-

250 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2950X1700X1800

-

Brand Name:

-

UnionTech

-

Model Number:

-

UT6150

-

Voltage:

-

220v/380v

-

Weight (KG):

-

2500

-

Marketing Type:

-

Hot Product

-

Brand:

-

UnionTech

-

Model:

-

UT6150

-

Controller:

-

FANUC/GSK/SIENMENS/SYNTEC

-

Turret Type:

-

4/6/8/12 Station

-

Usage:

-

Turning Milling Tapping Drilling Functions

-

CNC or Not:

-

CNC Lathe Machine

-

Precision:

-

0.008mm

-

Keyword:

-

Cnc Metal Lathe Machine

-

Product type:

-

Cnc Horizontal Turning Lathe Machine

-

Chuck:

-

Pneumatic Chuck

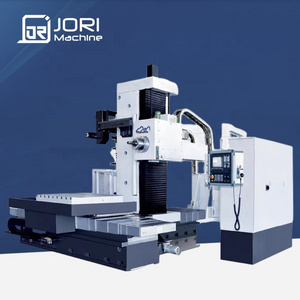

High Quality Lathe CNC Metal Machine Professional Metal Processing Flat Bed CNC Lathe With Factory Direct Sale Price

This machine tool is a CNC horizontal lathe with vertical (Z) and horizontal (X) two-coordinate control, featuring wide machining range, high rigidity, high precision, high speed, high efficiency, high reliability and high torque. It is capable of automatically completing the cutting of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, grooving, chamfering and other processes on a variety of shafts and disk parts, as well as turning metric and imperial straight threads, taper threads, end threads, etc., and a variety of turning processes.

It is suitable for the production of many varieties, small and medium-lot products, and it can show the superiority to the complex and high-precision parts.

|

Specifications

|

Unit

|

CK6140

|

CK6150

|

CK6160

|

||

|

Max. turning diameter on the bed

|

mm

|

Φ400

|

Φ500

|

Φ600

|

||

|

Max.turning diameter of the puller

|

mm

|

Φ20000

|

Φ290

|

Φ320

|

||

|

Max. processing length

|

mm

|

750/1000/1500

|

750/1000/1500/2000

|

750/1000/1500/2000

|

||

|

Main drive form

|

|

None

|

Three speeds (in-speed frequency conversion)

|

|

||

|

Spindle speed series

|

|

Rankingless

|

Rankingless

|

Rankingless

|

||

|

Spindle speed range

|

mm

|

50-2000

|

50-500/300-1100/600-1800

|

|

||

|

Spindle hole front taper

|

mm

|

MT5

|

MT6

|

MT6

|

||

|

Spindle motor power

|

kw

|

5.5

|

7.5

|

7.5/11

|

||

|

Chuck size

|

mm

|

200

|

250

|

250/320

|

||

|

Feed motor torque X/Z

|

|

4/6

|

5.5/7.5

|

5.5/7.5

|

||

|

Fast moving speed X/Z

|

m

|

X:6 Z:8

|

|

|

||

|

Repeated positioning accuracy(X/Z)

|

mm

|

±0.005

|

|

|

||

|

Workpiece surface roughness

|

|

Ral.6

|

|

|

||

|

Taistock sleeve diamemter

|

mm

|

60

|

75

|

75

|

||

|

Dimensions

|

mm

|

2500*1500*1650

|

2500*1500*1690

|

2500*1500*1820

|

||

|

Machine weight

|

kgs

|

1800

|

2000

|

2300

|

||

Characteristics:

Processing metal workpieces:

Metal lathes are mainly used for machining metal materials such as steel, iron, copper, aluminum, etc.

Rotating workpiece:

Metal lathes rotate the workpiece, which is clamped on the spindle, allowing the cutting tool to perform cutting operations on the workpiece.

Cutting tools:

Metal lathes use cutting tools such as turning tools, cutting inserts, etc., to remove excess material from the workpiece and achieve the desired shape and size.

Automatic feed:

Most metal lathes are equipped with an automatic feed mechanism, enabling the cutting tool to move along the axial direction of the workpiece automatically, resulting in more precise and efficient machining.

Different working modes:

Metal lathes can perform machining in longitudinal and transverse directions, accommodating different types and shapes of workpieces.

Versatility:

Metal lathes can perform various operations such as turning, boring, tapping, threading, making them highly versatile machine tools.

Precision and repeatability:

Metal lathes provide high precision and repeatability, ensuring the production of workpieces that meet specified requirements.

Suitable for small, medium, and large batch production:

Metal lathes are suitable for production in different scales, ranging from small batches to large-scale mass production.

Adjustments and settings:

Metal lathes allow adjustments and settings of cutting tool positions, angles, and feed rates to meet the machining requirements of different workpieces.

Part machining:

Metal lathes are widely used in the production of various components, such as shafts, gears, threads, pins, sleeves, etc. In manufacturing industries such as automotive, aerospace, shipbuilding, electronics, lathes are crucial equipment.

Thread machining:

Metal lathes can be used to create different types of threads, both internal and external. Threads are commonly used for mechanical connections, and lathes can precisely produce threads that meet the required standards.

Surface machining:

Metal lathes can also be used to machine complex surface shapes such as conical, spherical, etc., by adjusting the position and angle of the cutting tool.

Overhaul and maintenance:

During repair and maintenance processes, metal lathes are used to repair or rebuild damaged or worn-out components, restoring them to their normal working condition.

UnionTech Machinery Co., Ltd.

is a comprehensive technology enterprise specializing in the development, manufacturing, sales, and service of CNC machine tools. The company has a professional technical team dedicated to the field of CNC machine tool manufacturing, which has set a new banner in the CNC machine tool industry with over ten years of technical experience. There are currently five mainstream product series:

vertical machining center series

,

horizontal machining center series

,

CNC lathe

, and

gantry machining center series

.

The high-speed machining center machine in the vertical machining center series is our company's re promoted product. This series of machine tools has the characteristics of high speed, high rigidity, high performance, and high efficiency, and has quickly become the preferred machine tool equipment for industries such as communication, consumer electronics, automotive, and aerospace companies.

UnionTech Machinery Co., Ltd.

is based and means on precision machining, precision testing, and precision assembly, persistently pursuing high-end technology, highend market, and high-efficiency goals, closely following the forefront of industry technology, high standards, high starting points, and strict requirements.

Warranty &After-ale service

1.One-year warranty of the whole machine, new parts will be sent free within one year

2.Whole life technical support, update of software and controller, calibration of the machine, instruction of changing parts, technical problems solving and etc.;

3.Offering parts at cost beyond one year;

4.Online remote service by voice/video chat;

5.English-speaking engineers can go to your country to solve the problems.

Training:

1.English manual will be offered;

2. Videos of operating the machine will be taken and offered after the machine is finished;

3. Videos of software operation will be offered;

4. Free training if you can send engineer to our factory;

Door-to-door service

1.Install the machine;

2.Test and debug the machine till the machine works perfectly;

3.Train your technician how to operate the machine;

4.Train your technician how to program;

5.Tell you daily maintenance of the machine.

FAQ

1. Your products look similar, but the prices are different. What's the difference?

-The appearance are similar, but the models, parameters and configurations are different, so the prices are different. The better configuration, the higher prices. If you want to get an exact quotation, please contact customer service.

2. Can your offer customized service?

-Yes, we can. Please provide the specification for the machine you need, and tell us your requirements.

3.With so many machine tools, how to choose one that suits me?

-Please provide the requirements of the products you need to process: drawings, dimensions, size of workpeices etc.

we will recommend the suitable model for you according to the products you need to process.

4. Is your machine tool 3-axis, 4-axis or 5-axis?

-We have 3-5 axis machine tools, we need to know the size you need for 4th/ 5th rotary table, NC controller ,motor brand and models, so that we can offer the quotation to you.

Hot Searches