- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZhuHong

-

Model Number:

-

AISI M42/JIS SKH59 hs2-9-1-8 W2MO9CR4VCO8

-

Delivery condition:

-

Annealed

-

Material:

-

m42 high speed steel

-

Surface:

-

Polished Hot Rolled Steel

Quick Details

-

Steel Grade:

-

AISI M42/JIS SKH59 hs2-9-1-8 W2MO9CR4VCO8

-

Tolerance:

-

±20%

-

Grade:

-

M42

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZhuHong

-

Model Number:

-

AISI M42/JIS SKH59 hs2-9-1-8 W2MO9CR4VCO8

-

Delivery condition:

-

Annealed

-

Material:

-

m42 high speed steel

-

Surface:

-

Polished Hot Rolled Steel

AISI M42/JIS SKH59 hs2-9-1-8 W2MO9CR4VCO8 high speed tool steel

we have sold M2 round bar and flat bar to customer in poland,israel,Indonesia Ukraine,india

so if u nee these high speed steel,please contact us,we can send u pictures and mtc.

M42 steel (W2Mo9Cr4VCo8) is a high cobalt toughness high speed steel, mainly used for high toughness, precision wear-resistant metal cold stamping die, can also be used for cutting tools and knives cooling. High hardness of steel, up to 70HRC, good thermal hardness, high temperature, high hardness, easy grinding.

The cutting tools made of this steel can be used for cutting ferrous base superalloys, cast superalloys, titanium alloys and ultra high strength steels, but the toughness is slightly worse and the lower limit shall be adopted when quenching. As a result of good grinding performance, it can be used to manufacture a variety of high-precision complex cutting tools.

W2Mo9Cr4VCo8 steel named M42. super hard cobalt high speed tool steel grades of America, the mass fraction of M42 in steel vanadium is not high (1%), the mass fraction of cobalt high (8%), cobalt carbide in the quenching can make more dissolved in the matrix, improve wear resistance with high hardness. The hardness, hardness, abrasion resistance and grinding properties of the steel are very good. The hardness of the heat treatment is up to 67~70HRC, but there is also a special heat treatment method to obtain the hardness of 67 ~68HRC, so that the cutting performance (especially discontinuous cutting) is improved, and the impact toughness is improved. The steel can be made into a variety of cutting tools, cutting material difficult to process, the effect is very good, and because of its good grinding performance, can be made into complex cutting tools, but China's Cobalt resources are scarce, cobalt high-speed steel is expensive, about 5~8 times of ordinary high-speed steel

Standards:ASTM,JIS,GB,EN(DIN,BS,NF) Or Per as clients ’ requires.

Product Basic Information:

|

Material |

AISI M42 |

||

|

Chemical Composition |

Mechanical Properties(In Quenched & Tempered State) |

||

|

C |

1.05-1.15 |

Tensile strength(MPA) |

- |

|

Si |

0.15-0.65 |

Yield strength (MPA) |

- |

|

Mn |

0.15-0.40 |

Elongation(δ5/%) |

-- |

|

Cr |

3.50-4.25 |

Reduction in Area (ψ/%) |

- |

|

Mo |

9.00-10.00 |

Impact (J) |

- |

|

P |

≤ 0.030 |

Brinell Hardness (HBW) |

anneal <269 cooling with OIL preheating temperature 730-840c |

|

S |

≤ 0..030 |

||

|

W |

1.15-1.85 |

||

|

V |

0.95-1.35 |

||

2. Product Application Areas:

O ur products have been used in all kinds of ar e as, such as aviation , aerospace, navigation ,nuclear energy ,chemical industry,

electronic information, achine manufacture, petrochemical, automotive, instrument and meter, Communication , transportation, and medical instruments, etc.

3. S imilar steel grade & equivalent steel materials :

|

USA |

Japanese |

Gemany |

British |

France |

heat treatment |

Chinese |

|

ASTM&AISI&SAE |

JIS |

EN DIN |

EN BS |

EN NF |

ISO |

GB |

|

AISI M42 |

SKH59 |

HS 2-9-1-8 |

------ |

W2Mo9Cr4VCo8 |

||

Carbon tool steel can be obtained with high hardness and wear resistance. can be used for making tools with high hardness, flexibility, Wear-resisting performance .such as punch, blade.

Product Sales Information:

|

Material |

high speed steel |

|

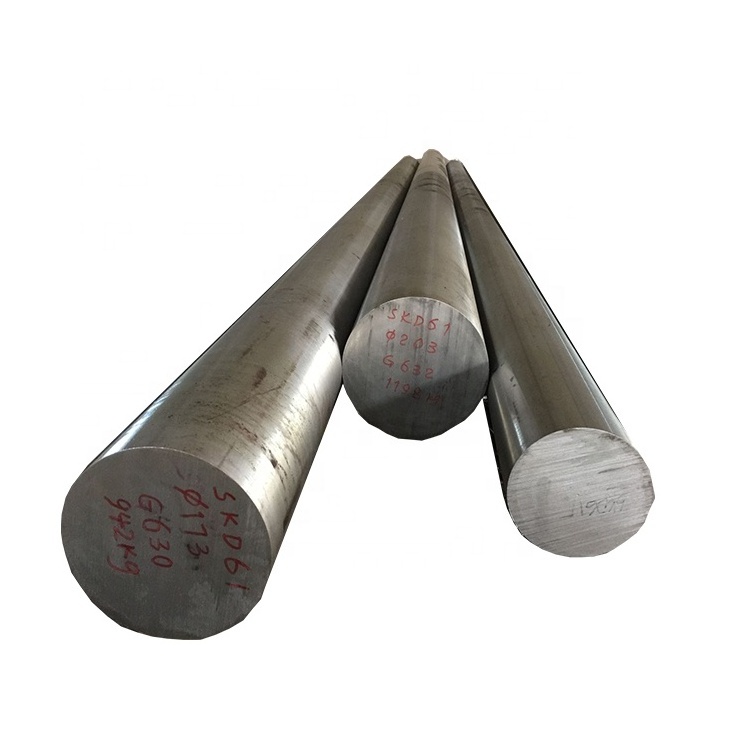

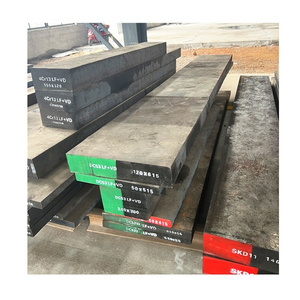

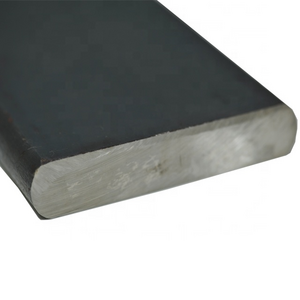

Size |

Diameter:20mm-1000mm Length:500mm-6000mm |

|

Origin place |

Made In China |

|

Delivery Condition |

Hot rolled,cold drawn,forged |

|

Surface require |

Black,grinding,bright,polish |

|

Heat treatment |

Quenched,Tempered,annealed |

|

Packing |

seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

|

Delivery time |

In 10-50 days |

|

Trade Term |

EXW,FOB,CIF |

|

Payments |

T/T or L/C at sight |

|

Port |

China main Port,such as shanghai,Dalian,Shenzhen port. |

|

MOQ |

1 Ton |

Company Main Products:

|

Alloy Steel |

5140,5115,5120,5130,5145,4118,4130,4135,6150,5115,4142,4130,4118,6150,4140,4720,4320 ,E9310,8620,4340 |

|

Tool Steel |

H13,1.2344,SKD61,D2,SKD11,1.2379,1.2510,01,SKS3,95MnWCr5,D3,SKD1,1.2419, SKS31,H21,SKD5,1.2581,P20,35CrMo7,1.2738,1.2316,M2,T7,Cr06,SUJ2,t5,t3,t4,M2 |

|

Bearing Steel |

GCr15,52100,SUJ1,SUJ2,100Cr6,1.2067,55C,8620,4320,9310,440C,M50,8620h |

|

Spring Steel |

9260,SUP6,SUP7,1.7108,54SiCr6,1.7102,5155,SUP9,1.7176,5160,1.7177,6150, SUP10,51CrV4,1.8159,SUP10, |

|

Stainless Steel |

317,sus321,1.405,304,SUS304,1.4301,410,SUS410,1.4006,420,1.4021,1.4028, 434,1.4113,316L,SUS316L,1.4435,630,1.4542,431,1.4057,201,202,301,304,305.316 |

Certifications:

Factory Manufacture Process:

1.Forged Ingot

2.Material Taking Machine

3.Forged Machine

4.Sawing Machine

5.Steel Grinding

6.Fished Steel Material

Products stocks:

Surface Polish bars

Surface Bright Bar

Black &Grinding surface bar