- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

URBAN

-

Dimension(L*W*H):

-

1600*750*1800 mm

-

Weight:

-

280 KG

-

Product name:

-

Desiccant Inserter Machine

-

capacity:

-

Max. 120 Bottles/Min ( Depend on bottle size )

-

Size of Container:

-

20-500ML

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

Max. 120 Bottles/Min ( Depend on bottle size )

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

URBAN

-

Dimension(L*W*H):

-

1600*750*1800 mm

-

Weight:

-

280 KG

-

Product name:

-

Desiccant Inserter Machine

-

capacity:

-

Max. 120 Bottles/Min ( Depend on bottle size )

-

Size of Container:

-

20-500ML

-

Certification:

-

CE

Products Description

|

Model

|

UBM-GS

|

|

Max.capacity

|

50-120 Bottles/Min ( Depend on bottle size )

|

|

Voltage

|

220V AC ,50Hz

|

|

Power

|

0.5KW

|

|

Overall Dimension

|

1600×750×1800 mm

|

|

Weight

|

180kg

|

Features

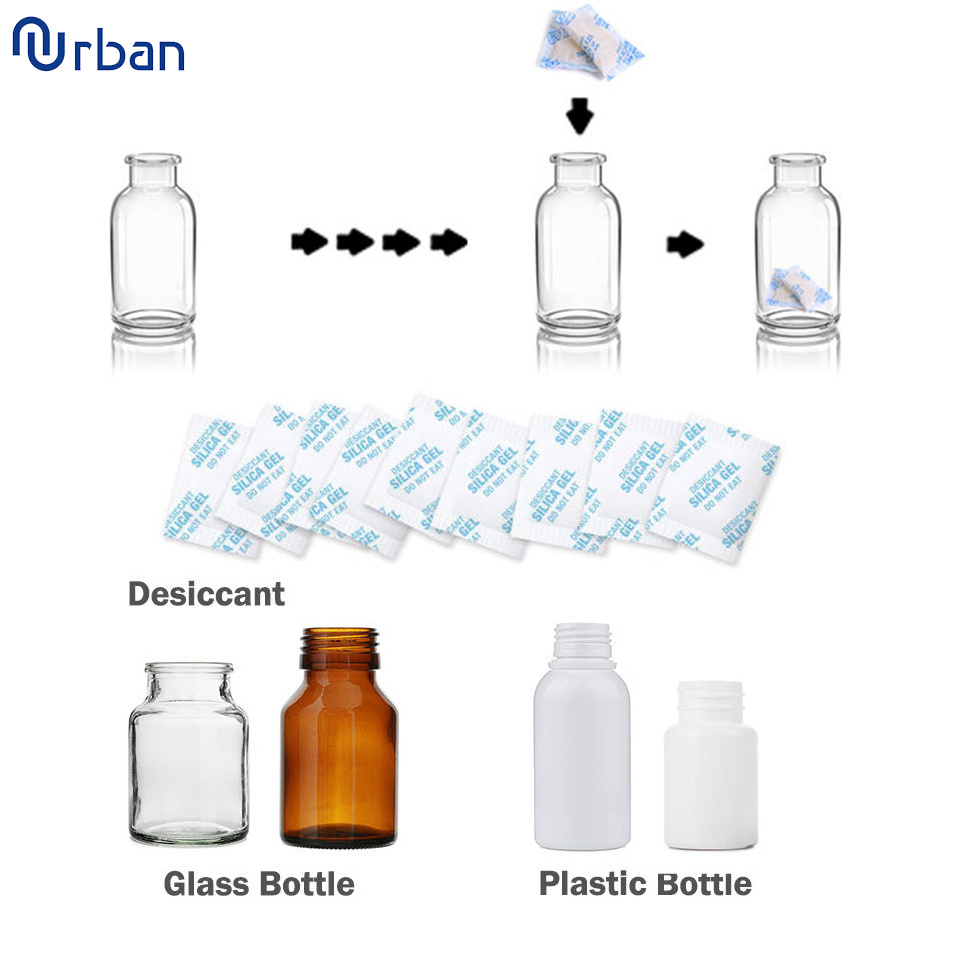

▪ Strong compatibility, suitable for round, oblate, square and oblate square bottles of various specifications and materials.

▪ Strong compatibility, suitable for round, oblate, square and oblate square bottles of various specifications and materials.

▪Color-coded and color-free disc-shaped bags of desiccant bags;

▪Adopt pre-release desiccant belt design to avoid uneven bag transfer and ensure the accuracy of bag length control. ▪Adopting desiccant bag thickness self-adaptive design for bag placement to avoid bag breakage during conveying.

▪ High durable blade, accurate and reliable cutting, will not cut the desiccant bag

▪ It has multiple detection alarm control functions such as no bottle not working, fault self-checking, desiccant bag not entering thebottle, etc., to ensure the continuity of equipment operation and the accuracy of the dryer bag filling.

▪ The operation of the whole system can only be linked to the upper and lower processes, with good coordination, no need for special personnel to operate, and labor saving

▪ The photoelectric sensor element is produced in Taiwan, which is stable and durable.

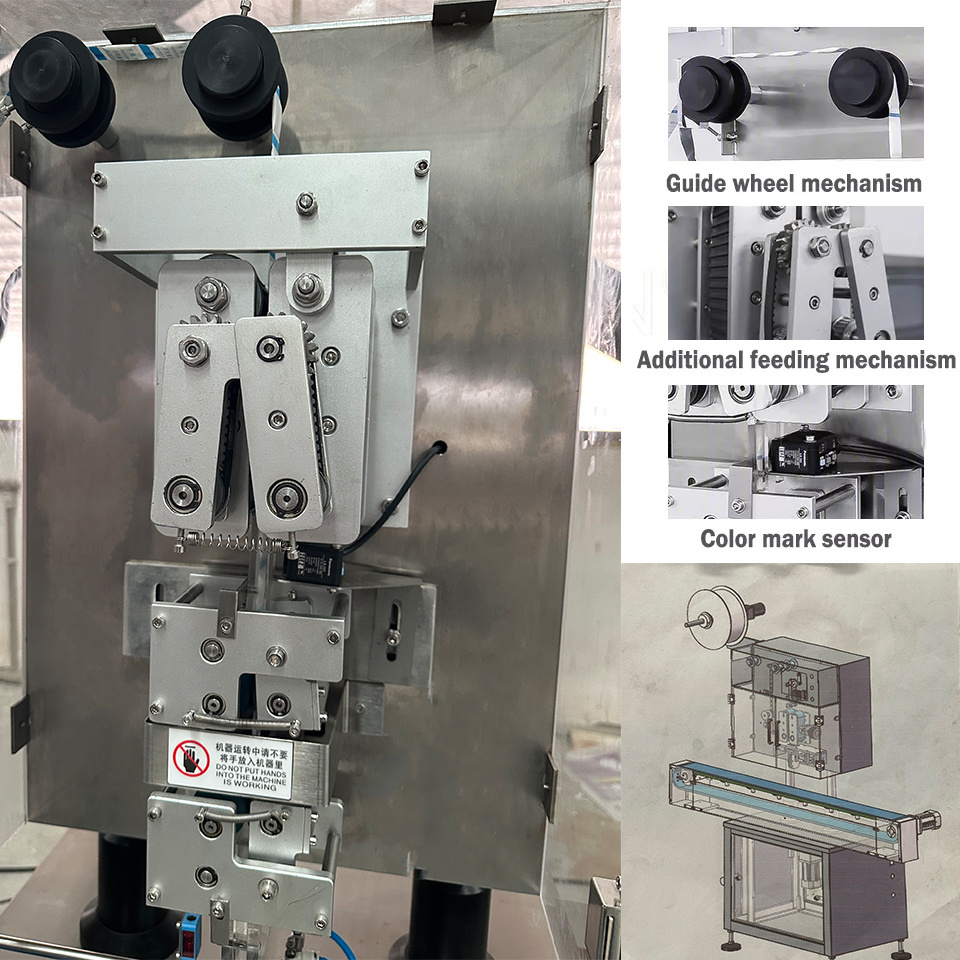

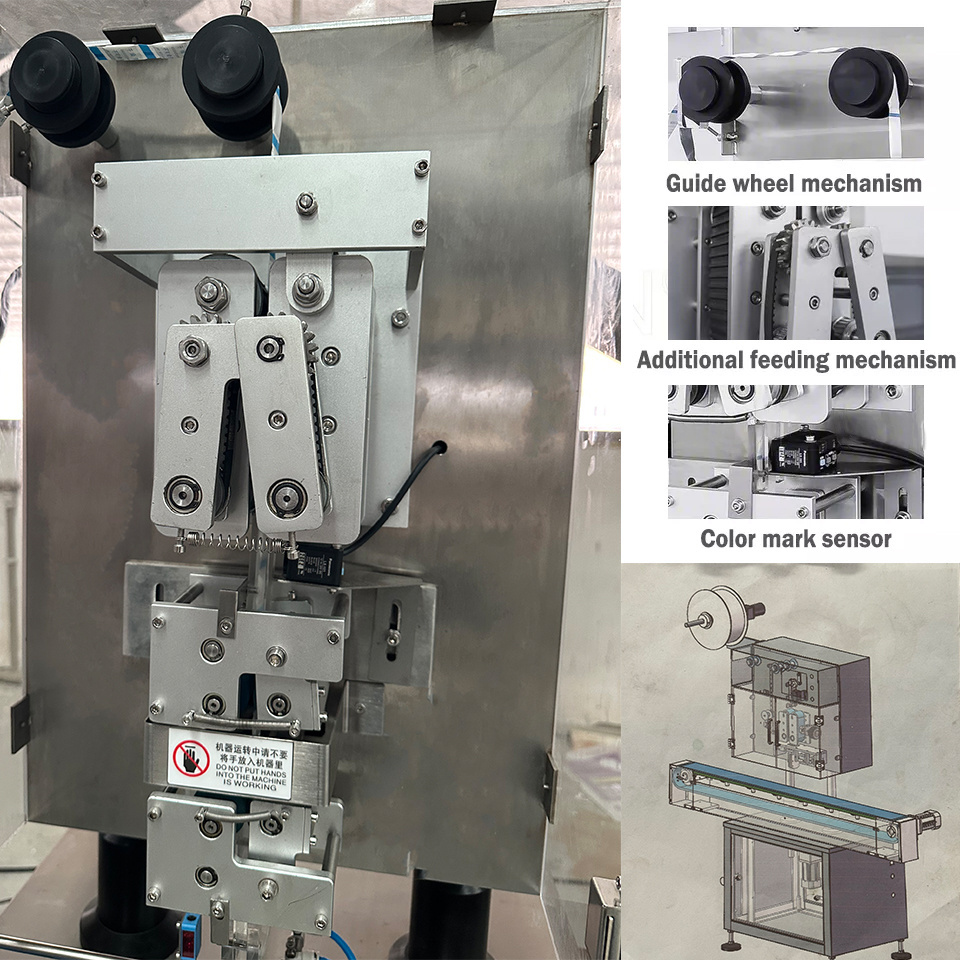

Detail Image

Structure chart

This machine is composed of desiccant roll, guide wheel mechanism, additional feeding mechanism, color mark sensor, conveyor belt,dust cover, touch screen and main frame.

Buyer Feedback

Hot Searches