- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.01%

-

SiC Content (%):

-

≥98

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

300x12 mm

-

Brand Name:

-

Supereal

-

Product name:

-

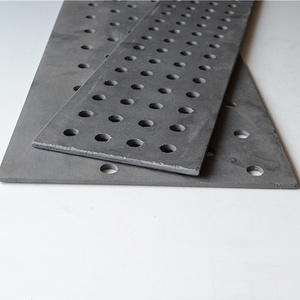

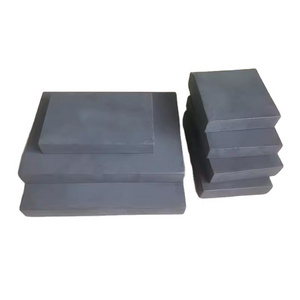

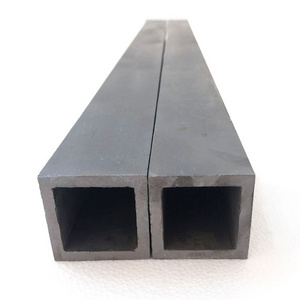

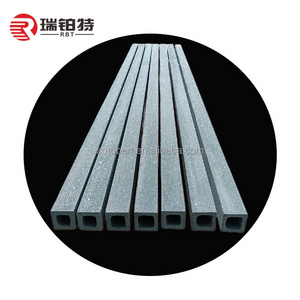

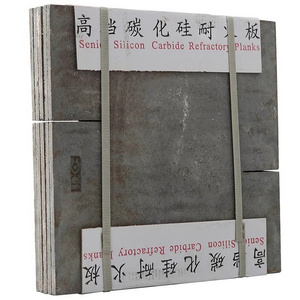

Sic Sintered Silicon Carbide Plate for Shuttle Kiln

-

Size:

-

300x12 mm

-

Application:

-

Shuttle Kiln

-

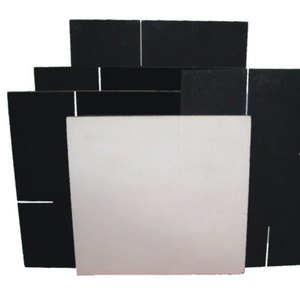

Color:

-

Grey / Black

-

Density:

-

≥2.75 g/cm3

-

Working temperature:

-

1400℃

-

Hardness:

-

13 Moh's

-

Thermal Conductivity:

-

30

-

Apparent porosity:

-

≤18

Quick Details

-

SiO2 Content (%):

-

9%

-

Al2O3 Content (%):

-

0

-

MgO Content (%):

-

0-0.05%

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.01%

-

SiC Content (%):

-

≥98

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

300x12 mm

-

Brand Name:

-

Supereal

-

Product name:

-

Sic Sintered Silicon Carbide Plate for Shuttle Kiln

-

Size:

-

300x12 mm

-

Application:

-

Shuttle Kiln

-

Color:

-

Grey / Black

-

Density:

-

≥2.75 g/cm3

-

Working temperature:

-

1400℃

-

Hardness:

-

13 Moh's

-

Thermal Conductivity:

-

30

-

Apparent porosity:

-

≤18

Sic Sintered Silicon Carbide Plate for Shuttle Kiln

Sic Sintered Silicon Carbide Plates have superior properties, such as high temperature resistance, corrosion resistance, high bending strength, the thermal conductivity of oxide bonded silicon carbide is 10 times than cordierite and high alumina kiln shelves, which is widely used in construction ceramics, sanitary ceramics, daily ceramics, electro ceramics, refractory material, powder metals sintered furnaces.

1.Technical parameters of Sic Sintered Silicon Carbide Plate for Shuttle Kiln:

| ITEM | UNIT | DATA |

| Temperature | ℃ | 1400 |

| Density | g/cm³ | ≥2.6 |

| Apparent porosity | % | ≤18 |

| Moh's Scale of Hardness | Moh'S | 13 |

| Bending Strength | MPa | 45 (20℃) |

| MPa | 55 (1200℃) | |

| Modulus of Elasticity | GPa | 250 (20℃) |

| Thermal Conductivity | W/m.k | 30 (1200℃) |

| Coefficient of thermal expansion | k -1 ×10 -6 | 4.3 |

| Acid Alkaline -proof | Excellent |

2. Property of Sic Sintered Silicon Carbide Plate for Shuttle Kiln:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1400℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Longer service life

3. Normal Specification of Sic Sintered Silicon Carbide Plate for Shuttle Kiln :

| Item |

LengthxWidth (mm) |

LengthxWidth (mm) |

LengthxWidth (mm) |

LengthxWidth (mm) |

LengthxWidth (mm) |

| 1 | 765x730 | 600x600 | 520x490 | 460x440 | 400x380 |

| 2 | 760x550 | 600x550 | 520x400 | 460x350 | 400x350 |

| 3 | 760x520 | 600x520 | 500x500 | 460x320 | 400x300 |

| 4 | 760x500 | 600x500 | 500x480 | 450x450 | 400x250 |

| 5 | 740x520 | 600x400 | 500x450 | 450x430 | 380x380 |

| 6 | 732x445 | 600x370 | 500x400 | 450x420 | 365x365 |

| 7 | 720x630 | 600x300 | 500x390 | 450x400 | 350x350 |

| 8 | 700x700 | 570x500 | 500x370 | 450x380 | 350x300 |

| 9 | 700x550 | 560x270 | 500x300 | 450x350 | 340x340 |

| 10 | 700x520 | 550x550 | 490x470 | 450x340 | 340x320 |

| 11 | 700x500 | 550x520 | 480x480 | 450x300 | 340x310 |

| 12 | 700x450 | 550x500 | 480x420 | 440x440 | 330x330 |

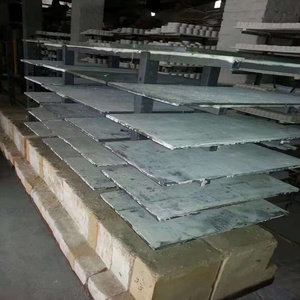

4, Application of Sic Sintered Silicon Carbide Plate for Shuttle Kiln :

Silicon carbide ceramic can be made into OSiC plate, OSiC support, OSiC disc and other special shaped products, which are mostly used as kiln furniture like batts, setter plate, pusher plate, setter slab, sagger,muffle board and support shelves in firing tableware, sanitary ceramics, electrical ceramics, emery wheel and so on.

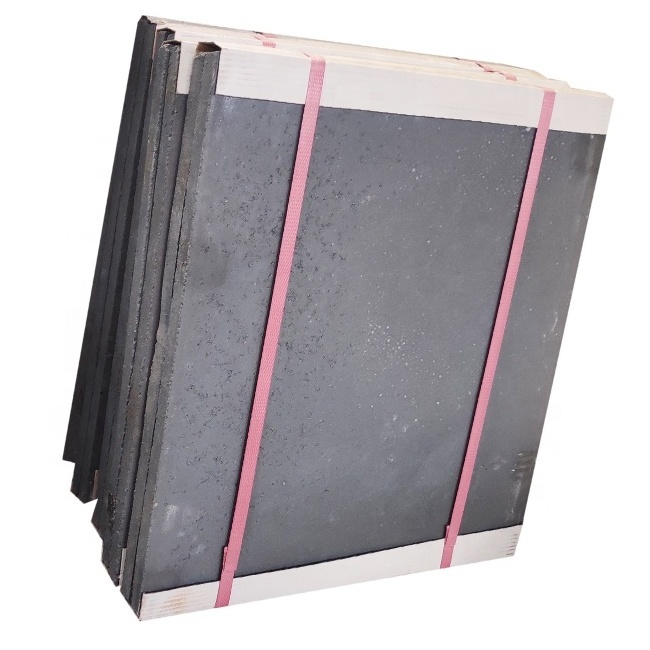

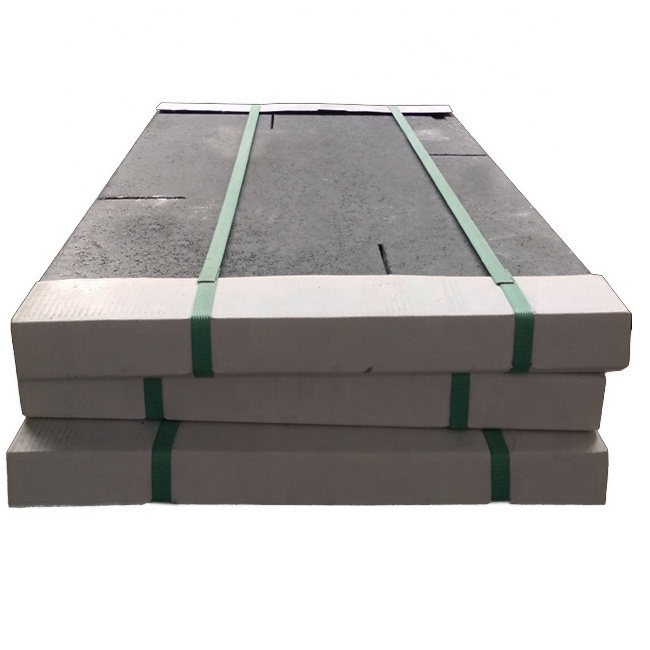

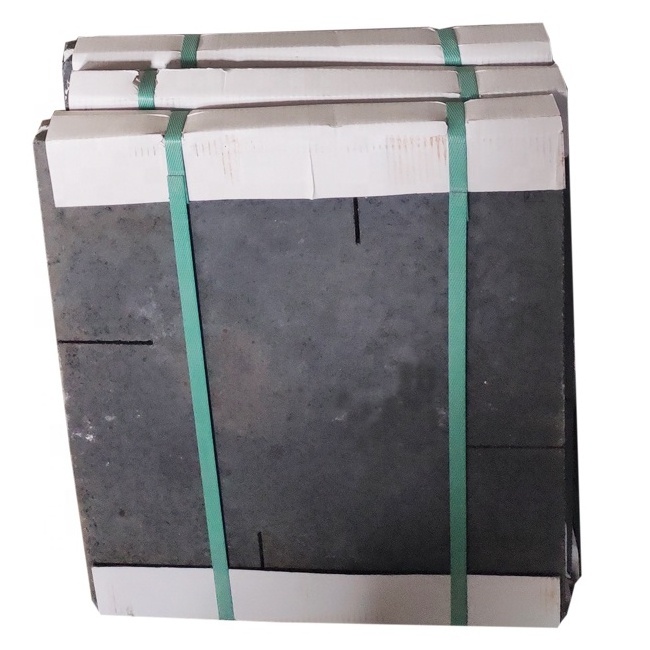

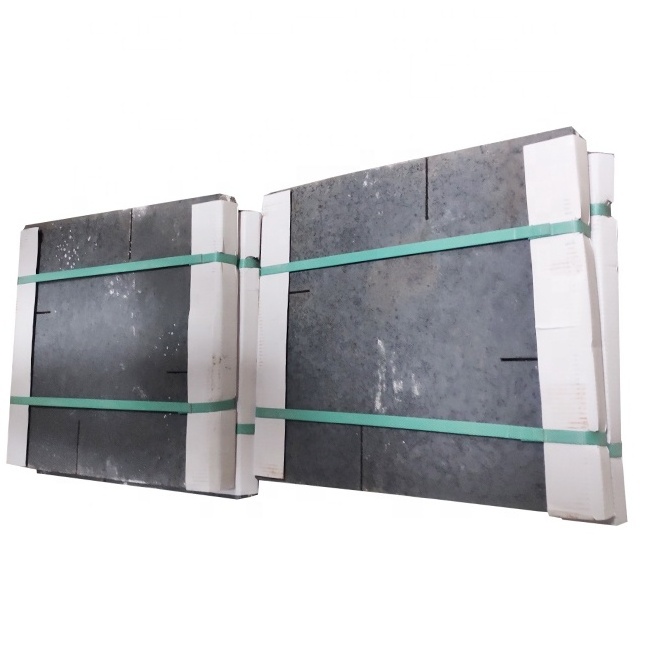

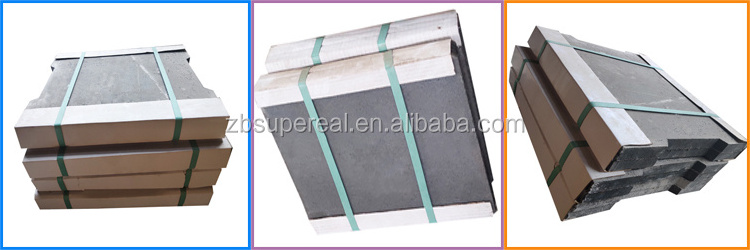

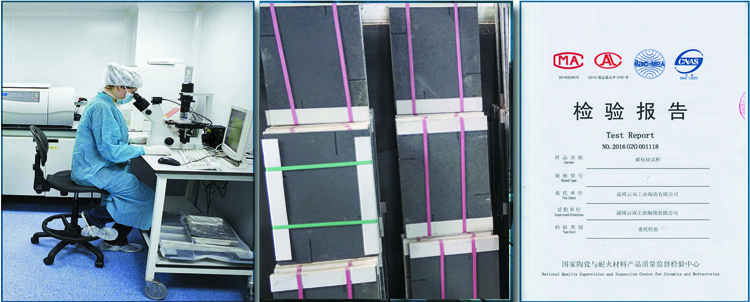

5. Packing of Sic Sintered Silicon Carbide Plate for Shuttle Kiln: