- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

fudao

-

Model Number:

-

customizable

-

Width:

-

600-1500

-

Length:

-

customizable

-

Product Name:

-

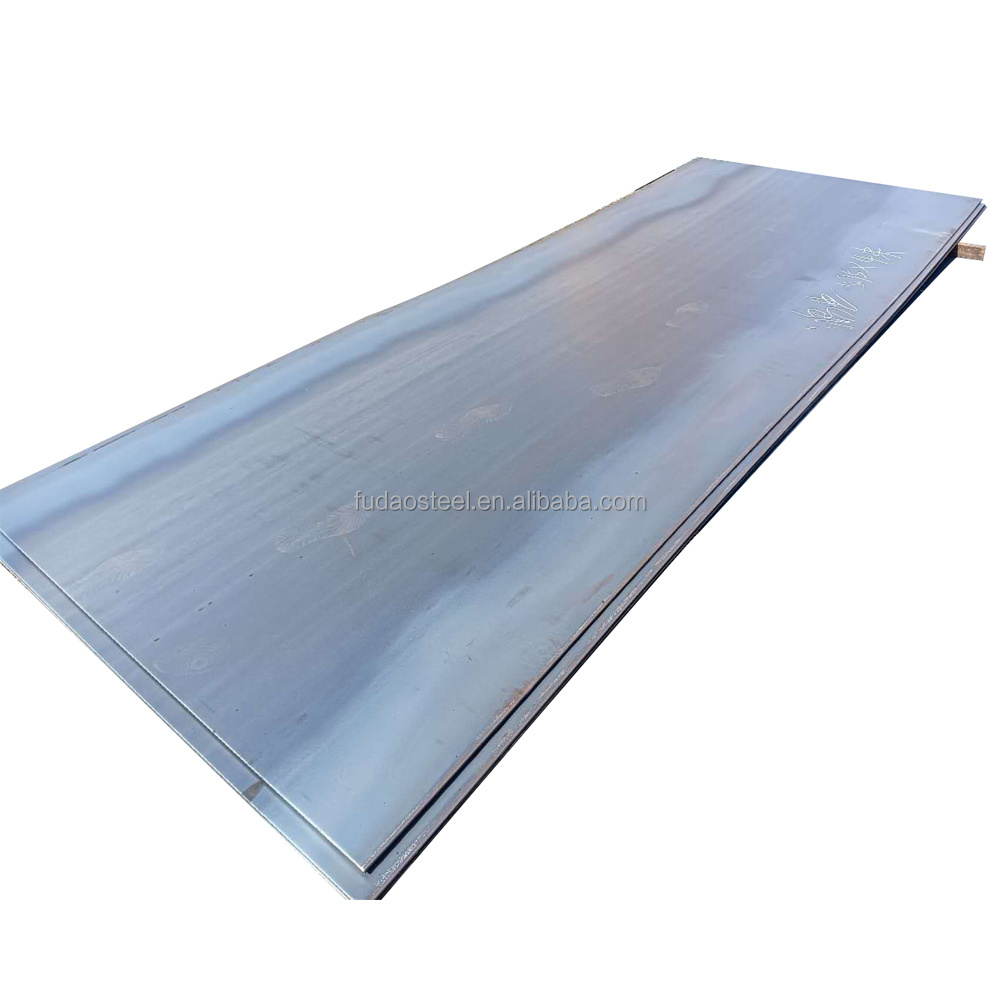

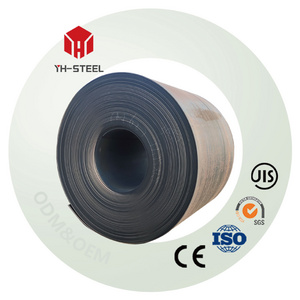

hot-rolled steel coil hot rolling mild black steel

-

Material:

-

Q235/Q235B/Q345/Q345B/Q195/St37/St42/St37-2/St35.4/St52.4/St35

-

Technology:

-

Hot Rolled Steel Sheet Plate

-

Thickness:

-

0.1mm-300mm

-

Coil Weight:

-

3-5tons

-

Packing:

-

Exported Sea Worthy Packing

-

Shape:

-

Coil Roll

-

MOQ:

-

10 Tons

-

Usage:

-

Construction Structure

-

Price term:

-

CIF CFR FOB EX-WORK

Quick Details

-

Grade:

-

customizable

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

fudao

-

Model Number:

-

customizable

-

Width:

-

600-1500

-

Length:

-

customizable

-

Product Name:

-

hot-rolled steel coil hot rolling mild black steel

-

Material:

-

Q235/Q235B/Q345/Q345B/Q195/St37/St42/St37-2/St35.4/St52.4/St35

-

Technology:

-

Hot Rolled Steel Sheet Plate

-

Thickness:

-

0.1mm-300mm

-

Coil Weight:

-

3-5tons

-

Packing:

-

Exported Sea Worthy Packing

-

Shape:

-

Coil Roll

-

MOQ:

-

10 Tons

-

Usage:

-

Construction Structure

-

Price term:

-

CIF CFR FOB EX-WORK

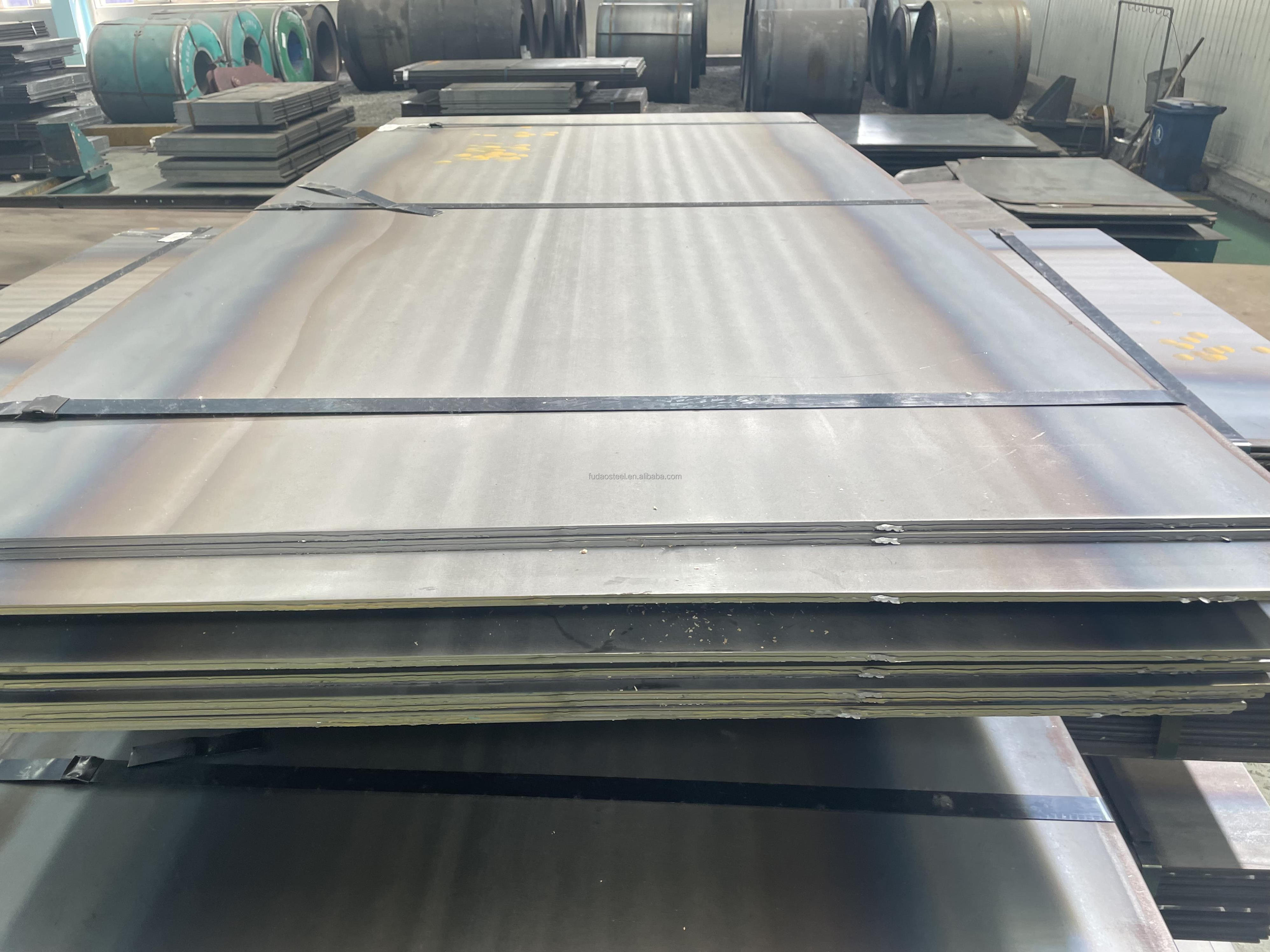

Products Description

Hot Rolled Steel Coil/Plate

Hot rolled steel is an alloy consisting of iron and carbon. The percentage of carbon in the steel affects the hardness,strength of elasticity and ductility of carbon steel. As the carbon percentage content rises, steel is harder and strongerbut less ductile. Hot rolled steel has high hardness, toughness and strength, and it is relatively inexpensive compared toother steels.

Product Specification

|

Material Grade

|

Q235,Q345,ST37,A36,16Mn,45#,SPHC

|

|

|

|

|

Thickness

|

0.75mm-300mm

|

|

|

|

|

Width

|

plate:600-2250mm,strip:24-600mm

|

|

|

|

|

Length

|

1m-12m or as customer's requirements

|

|

|

|

|

Standard

|

GB/T700-2006, GB/T1591-2008, GB/T709-1988

|

|

|

|

|

Edge Type

|

Scrap edge(Q); No trimming(BQ)

|

|

|

|

|

Delivery time

|

7-10days after the deposit or copy of LC, 20days if the quantity beyond 1000tons.

|

|

|

|

Hot Rolled Steel Coil Process

The first step in the hot rolling process is to heat the steel, elemental or mineral mixture to a high temperature above its recrystallization temperature. Once it is heated above this point, the steel becomes ductile. It is then sent to a rolling machine where it can be easily shaped. With this hot-rolled carbon steel process, it can produce large quantities of steel in a single batch as minimal additional machining is required.

After carbon steel is processed, it is normalized by cooling to room temperature. The process of heating and slow cooling of steel changes the metal's microstructure, increasing its ductility and strength. When forming steel, increasing ductility is an important factor in obtaining the desired shape. The exact combination of elements added to the iron content determines the grade of steel and its unique strength, formability and hardness properties. Carbon and manganese are the two main additional elements that affect the outcome of a particular grade of material, but other elements can also play a key role.

In addition, hot rolled steel shrinks slightly during the cooling phase, resulting in a slight change in accuracy; thickness and width of the coil. The finished product does not always meet the specific goals originally intended. Therefore, for flat steel products, there are standard tolerances and ranges defined by the industry. The production of hot rolled steel is both an art and a science that really requires a delicate balance. Often, additional and off-the-shelf treatments are required for areas that require tight tolerances. Hot-rolled mild steel has been rolled at high temperatures from slabs of cast steel over two inches thick to coils as thin as 1/16-inch thick.

Because the steel is hot rolled, the degree of reduction from the slab to the coil is high, so the surface of the coil is noticeably rough and slightly oxidized. Recommended for hot rolled strip of precise thickness and high formability.

Hot-rolled mild steel is less expensive than cold-rolled steel because it is not treated after hot rolling except that it requires pickling to remove surface scale. Hot Rolled Steel Coil Factory provides hot rolled mild steel plate and coil for your application.

After carbon steel is processed, it is normalized by cooling to room temperature. The process of heating and slow cooling of steel changes the metal's microstructure, increasing its ductility and strength. When forming steel, increasing ductility is an important factor in obtaining the desired shape. The exact combination of elements added to the iron content determines the grade of steel and its unique strength, formability and hardness properties. Carbon and manganese are the two main additional elements that affect the outcome of a particular grade of material, but other elements can also play a key role.

In addition, hot rolled steel shrinks slightly during the cooling phase, resulting in a slight change in accuracy; thickness and width of the coil. The finished product does not always meet the specific goals originally intended. Therefore, for flat steel products, there are standard tolerances and ranges defined by the industry. The production of hot rolled steel is both an art and a science that really requires a delicate balance. Often, additional and off-the-shelf treatments are required for areas that require tight tolerances. Hot-rolled mild steel has been rolled at high temperatures from slabs of cast steel over two inches thick to coils as thin as 1/16-inch thick.

Because the steel is hot rolled, the degree of reduction from the slab to the coil is high, so the surface of the coil is noticeably rough and slightly oxidized. Recommended for hot rolled strip of precise thickness and high formability.

Hot-rolled mild steel is less expensive than cold-rolled steel because it is not treated after hot rolling except that it requires pickling to remove surface scale. Hot Rolled Steel Coil Factory provides hot rolled mild steel plate and coil for your application.

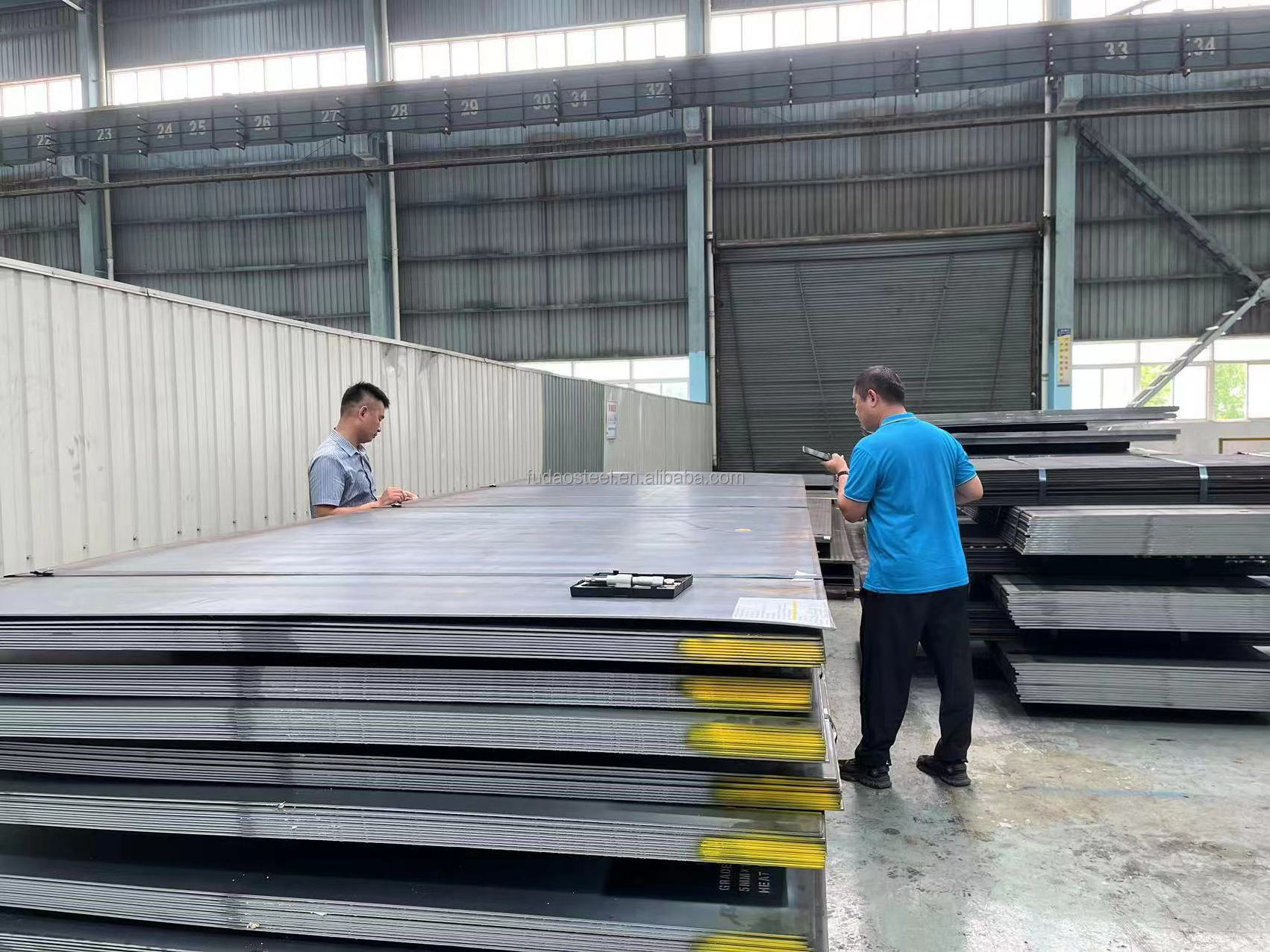

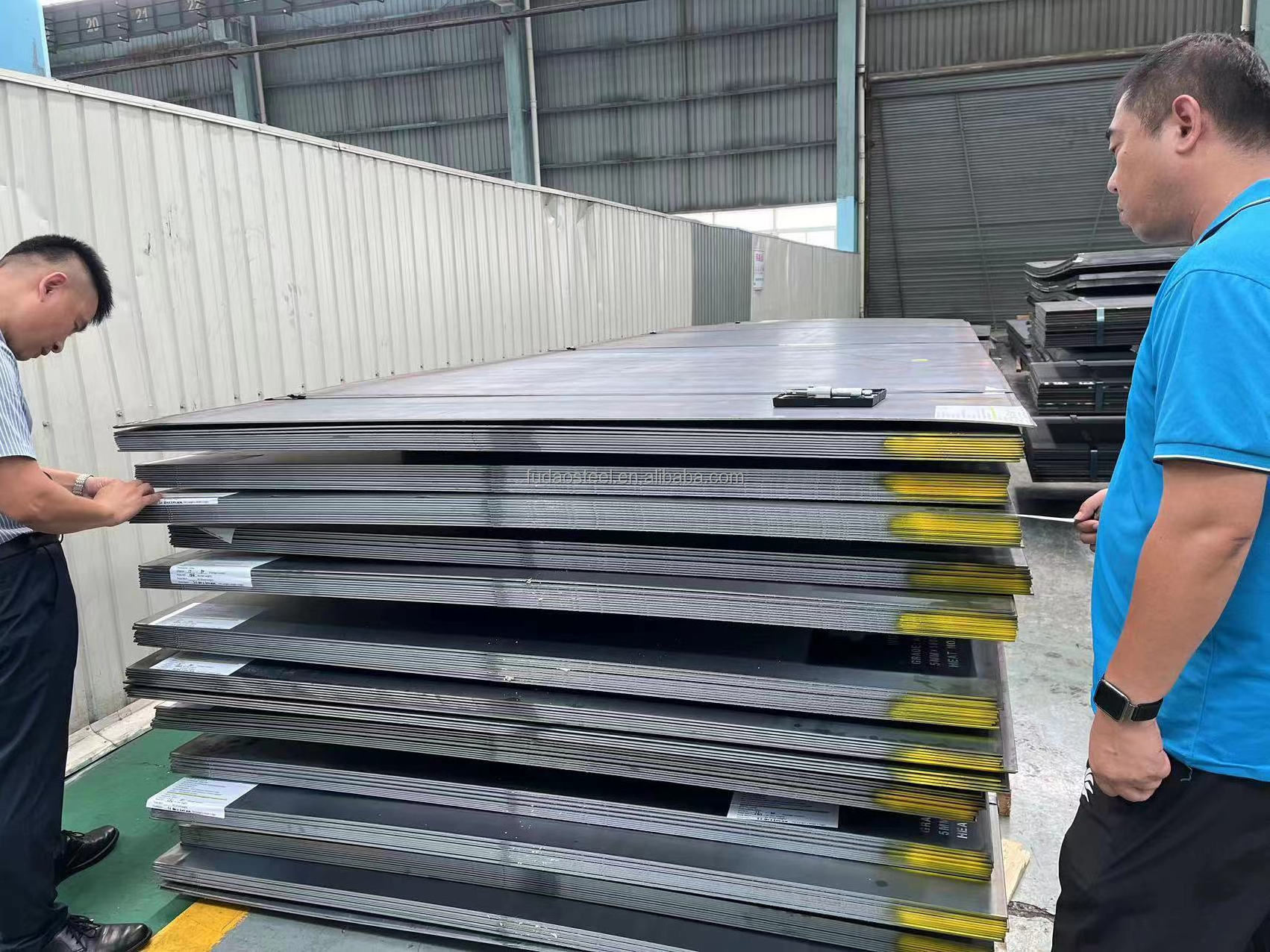

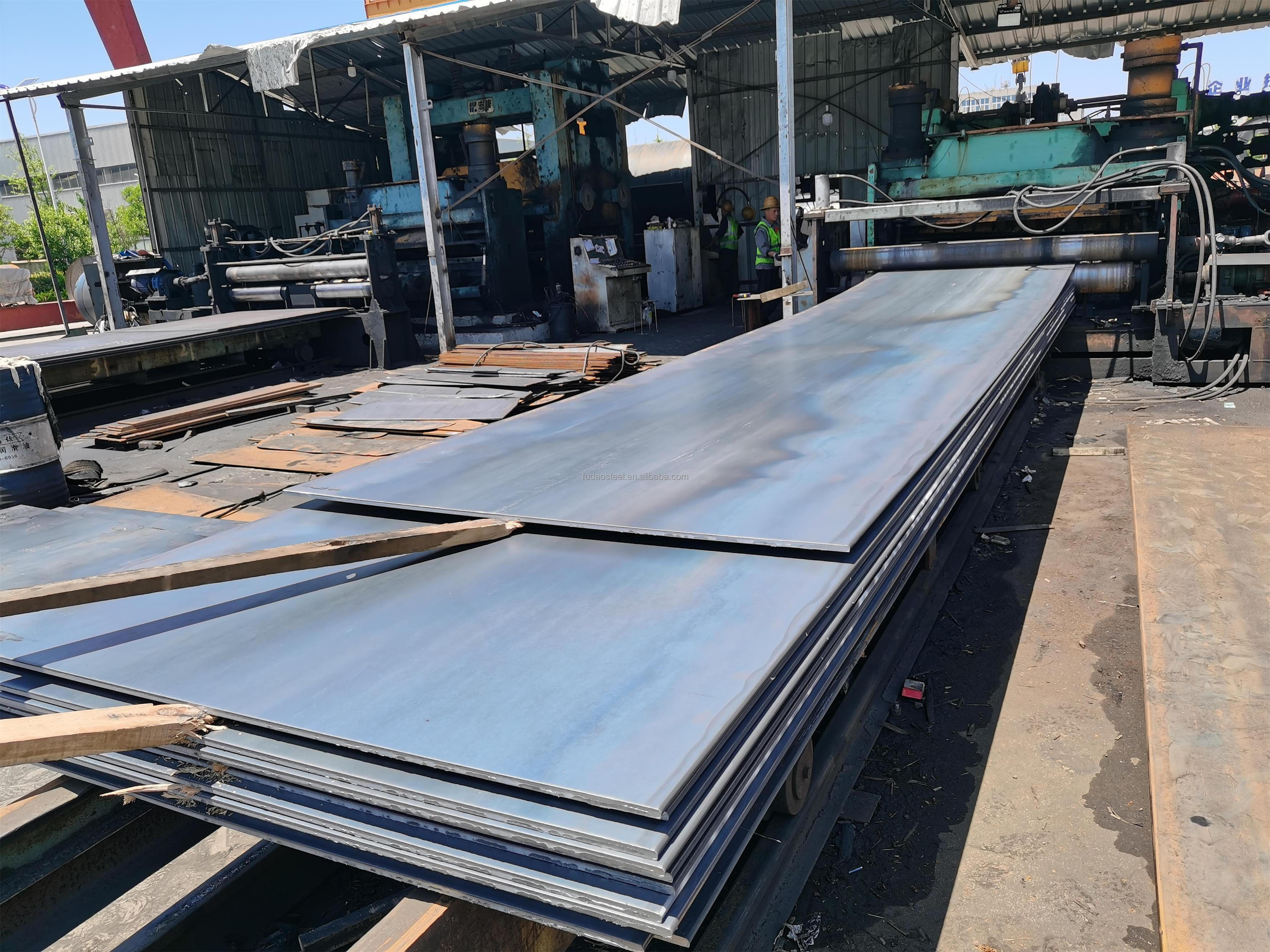

Factory Show

Packing & Delivery

Hot Searches