- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

≤2.0%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Henan, China

Quick Details

-

SiO2 Content (%):

-

≤2.0%

-

Al2O3 Content (%):

-

0

-

MgO Content (%):

-

≥94.5%

-

CaO Content (%):

-

≤2.0%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Henan, China

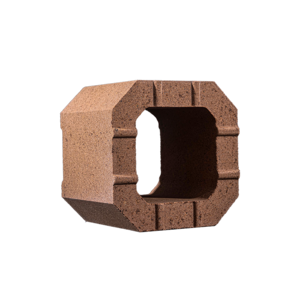

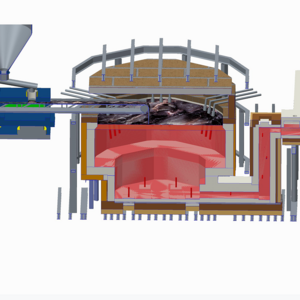

Chimney checker block/ magnesia brick for regenerator of glass furnace melting

1.The products are fused magnesia as main raw material, after a reasonable size distribution, high pressure forming, high-temperature sintering. The product has strong resistance to slag corrosion ability and high temperature dimensional stability. Mainly used in glass furnace regenerator, the upper part.

2.The regular magnesia bricks are made from dense dead burned magnesia that makes the bricks in good refractoriness, corrosion-resistance, and widely used in checker chamber of glass tank, lime kiln, non-ferrous metallurgical furnaces, open heart furnace, iron mixer and EAF of steel-making, and also ferro-alloy furnace, etc.

The bricks with MgO 95% or more in content take the secondary-burning dead burned magnesia or electrofused magnesia as the raw material and bured under the condition of ultra high temperature. They have the features of highly directly bonded and corrosion-resistance and widely used in various kinds of high temperature kilns and furnaces

P hysical and chemical index:

|

|

|

Quality Magnesia Brick |

||||

|

MZ-91 |

MZ-92 |

MZ-95 |

MZ-96 |

MZ-97 |

MZ-98 |

|

|

MgO % |

≥91 |

≥92 |

≥94.5 |

≥95.5 |

≥96.5 |

≥97.5 |

|

SiO 2 % |

≤3.5 |

≤3.0 |

≤2.0 |

≤1.5 |

≤1.0 |

|

|

CaO % |

≤3 |

≤2.5 |

≤2.0 |

≤1.8 |

≤1.5 |

≤1.2 |

|

Apparent Porosity % |

≤18 |

≤18 |

≤18 |

≤18 |

≤17 |

≤17 |

|

Cold Crushing Strength Mpa |

≥58 |

≥60 |

≥60 |

≥60 |

≥60 |

≥60 |

|

Bulk Density g/cm 3 |

≥2.9 |

≥2.9 |

≥2.95 |

≥3.0 |

≥3.05 |

≥3.1 |

|

0.2Mpa Refractoriness Under Load T 0.6 |

≥1550 |

≥1600 |

≥1650 |

≥1650 |

≥1700 |

≥1700 |

|

Thermal Stability 950°C Wind cycles |

|

|

≥20 |

≥20 |

≥20 |

≥20 |

|

Reheat liner change 1650°C×2h % |

≤0.5 |

|

|

|

|

|

Magnesia bricks for upper layer of regenerator checker

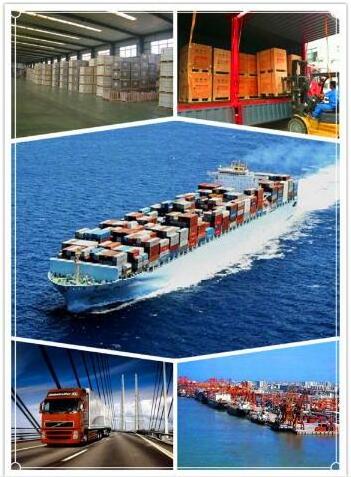

Packaging & Shipping