- Product Details

- {{item.text}}

Quick Details

-

Travel (X Axis)(mm):

-

400 mm

-

Travel (Y Axis)(mm):

-

400 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CAMEL CNC

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1420*950*1420mm

-

Power (kW):

-

3

-

Weight (KG):

-

320

-

Warranty:

-

2 Year

-

Working area:

-

360*360mm

-

Spindle:

-

1.5KW/2.2KW

-

Control system:

-

NC-STUDIO control (DSP option)

-

Motor and driver:

-

Stepper motor or servo motor

-

Inverter:

-

Fuling Inverter

-

X,Y,Z:

-

TBI ball screw

-

Table:

-

T-slot Table

-

Command Language:

-

G Code

-

Software:

-

Artcam/Type3

-

Product name:

-

CA-3636 CNC Advertising Wood Working Machine

-

Certification:

-

CE

Quick Details

-

Working Table Size(mm):

-

300×400

-

Machine Type:

-

CNC Router

-

Positioning Accuracy (mm):

-

0.03 mm

-

Travel (X Axis)(mm):

-

400 mm

-

Travel (Y Axis)(mm):

-

400 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CAMEL CNC

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1420*950*1420mm

-

Power (kW):

-

3

-

Weight (KG):

-

320

-

Warranty:

-

2 Year

-

Working area:

-

360*360mm

-

Spindle:

-

1.5KW/2.2KW

-

Control system:

-

NC-STUDIO control (DSP option)

-

Motor and driver:

-

Stepper motor or servo motor

-

Inverter:

-

Fuling Inverter

-

X,Y,Z:

-

TBI ball screw

-

Table:

-

T-slot Table

-

Command Language:

-

G Code

-

Software:

-

Artcam/Type3

-

Product name:

-

CA-3636 CNC Advertising Wood Working Machine

-

Certification:

-

CE

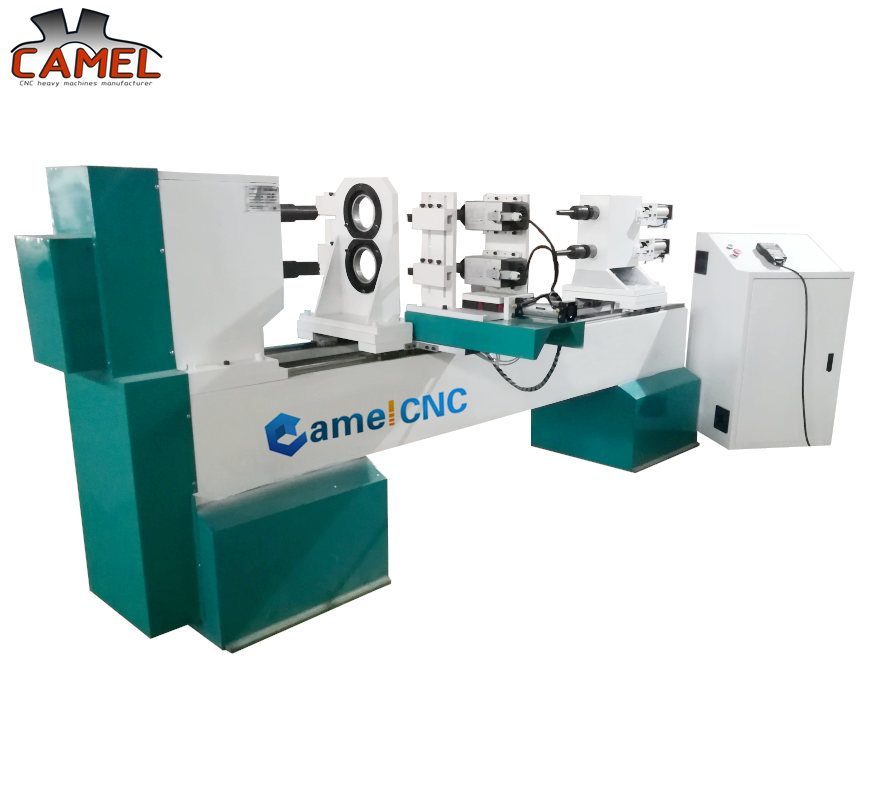

CAMEL CNC 3D Metal Milling Machine CNC Metal Engrave Machine For Metal CA-3636 360*360mm

Applications

Signmaking - All types of 2D and 3D signs in woods, metals and plastics

Metal Fabrication - Non-ferrous part manufacturing

Plastic Fabrication - Engineering plastics, retail and point of sale

Solid Surface - Process modern and traditional materials

General Woodworking - Furniture, shopfitting, scenery production and more

Graphics and Print Finishing - Cut-to-print using multiple tools for all materials

Exhibition Stands - Large format routing for all requirements

Scenery and Sets - Fast turnaround and high quality processing

Foam Packaging - 2D and 3D processing with router and knife tools

Interiors - Multi-purpose routing and engraving in all materials

Point of Purchase - Display stands, fixtures and fittings

Performance Parameter

|

Number |

Description |

Parameter |

|

1 |

X,Y,Z Working Area |

360x360mm |

|

2 |

Table Size |

1260X1420mm |

|

3 |

X,Y,Z Traveling Positioning Accuracy |

±0.01/300mm |

|

4 |

X,Y,Z Repositioning Accuracy |

±0.01mm |

|

5 |

Table Surface |

T-Slot Table |

|

6 |

Frame |

Welded Steel Tube Structure |

|

7 |

X, Z Structure |

Round Rails and TBI Ball Screw, |

|

8 |

Y Structure |

Hiwin Rail Linear Bearings and Ball Screw |

|

9 |

Max. Power Consumption |

0.8Kw( Without Spindle) |

|

10 |

Max. Rapid Travel Rate |

10000mm/min |

|

11 |

Max. Working Speed |

6000mm/min |

|

12 |

Spindle Power |

1.5Kw Water Cooling Spindle |

|

13 |

Spindle Speed |

0-24000RPM |

|

14 |

Drive Motors |

Stepper System |

|

15 |

Working Voltage |

AC380V/50/60Hz, (AC220V) |

|

16 |

Command Language |

Command Language |

|

17 |

Operating System |

DSP System (options: Ncstudio/Mach3 PC Software) |

|

18 |

Collet |

ER16 |

|

19 |

X,Y Resolution |

<0.01mm |

|

20 |

Software Compatibility |

Type3/UcancameV9 Software (Option: Artcam software) |

|

21 |

Running Environment Temperature |

0 - 45 Centigrade |

|

22 |

Relative Humidity |

30% - 75% |

Detailed Imagines

Detailed Samples