Automatic empty aluminum cans depalletizer is mainly used for automatic unloading of empty cans. The empty cans stacked on the

pallet, from bottom to top layer of lift and push to the net conveyor and matching use with inline cans rinser which is the ideal

equipment of medium-sized and large beverage manufacturers essential.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

100%

-

Voltage:

-

110/220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2100*1200*1900mm

-

Weight:

-

3800 KG

-

Product name:

-

Beer Filling Machine

-

Filling volume:

-

8oz, 12oz, 16oz, 250ml, 330ml, 500ml and so on

-

Filling speed:

-

6000-8000CPH

-

Filling material:

-

Beer,carbonated drink,cola,energy drink

-

Filling type:

-

Count Pressure Filling System

-

Packaging type:

-

Aluminum Tin PET Can

-

Function:

-

Can Washing Filling Seaming

-

Material:

-

SUS304/SUS316

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen+transducer

Quick Details

-

Machinery Capacity:

-

Other, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, 2000-10000CPH

-

Packaging Material:

-

Plastic, Metal, Other

-

Filling Material:

-

Beer, Juice

-

Filling Accuracy:

-

100%

-

Voltage:

-

110/220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2100*1200*1900mm

-

Weight:

-

3800 KG

-

Product name:

-

Beer Filling Machine

-

Filling volume:

-

8oz, 12oz, 16oz, 250ml, 330ml, 500ml and so on

-

Filling speed:

-

6000-8000CPH

-

Filling material:

-

Beer,carbonated drink,cola,energy drink

-

Filling type:

-

Count Pressure Filling System

-

Packaging type:

-

Aluminum Tin PET Can

-

Function:

-

Can Washing Filling Seaming

-

Material:

-

SUS304/SUS316

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen+transducer

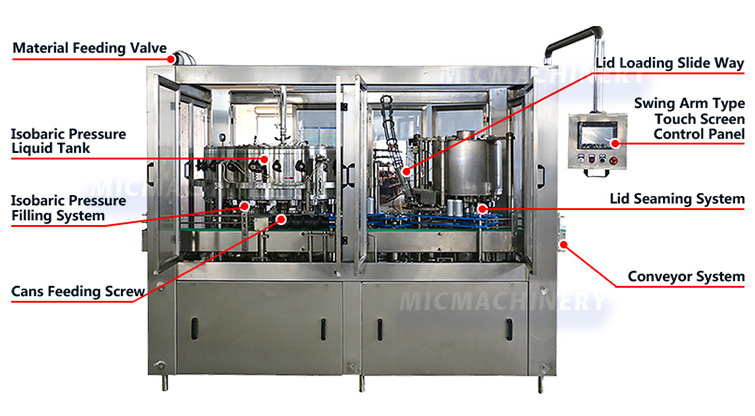

Mic 24-6 carbonated drinks filling machine adopts isobaric pressure filling system which is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius) If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, herbal tea and so on.

Machine features:

1. Mic 24-6 carbonated beveragecan filling machine is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and seaming part is the overall designed, in order to ensure that both the absolute synchronization and coordination.

2.The machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control, no can no filling and so on.

3.Isobaric filling system, controlled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degrees Celsius).

4.Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all.

5.It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small brewery and medium beverage plant

6.Aluminum can and metal can are both availableworking on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase.

7.If Cansstock on conveyorthen sensor will inform PLC to stop the Can feeding.

8.About machine test and shipment, we are stick with real production test till all problem is fix and then ship out.

1. Mic 24-6 carbonated beveragecan filling machine is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and seaming part is the overall designed, in order to ensure that both the absolute synchronization and coordination.

2.The machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control, no can no filling and so on.

3.Isobaric filling system, controlled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degrees Celsius).

4.Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all.

5.It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small brewery and medium beverage plant

6.Aluminum can and metal can are both availableworking on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase.

7.If Cansstock on conveyorthen sensor will inform PLC to stop the Can feeding.

8.About machine test and shipment, we are stick with real production test till all problem is fix and then ship out.

|

Model/Parameter

|

MIC-12-1

|

MIC-18-1

|

MIC-18-6

|

MIC-24-6

|

MIC-32-8

|

||||

|

Application

|

Beer, carbonated beverage, gas drinks, cold coffee, sparkling water, cider, soda water, herbal tea, non-carbonated drinks and so on

|

|

|

|

|

||||

|

Packing Type

|

Aluminum cans, tin cans, pet cans, etc

|

|

|

|

|

||||

|

Capacity

|

1000-2000CPH

|

1000-2500CPH

|

3000-6000CPH

|

4000-8000CPH

|

6000-10000CPH

|

||||

|

Filling Range

|

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L)

|

|

|

|

|

||||

|

Power

|

1.1KW

|

1.5KW

|

2.5KW

|

3.5KW

|

4.2KW

|

||||

|

Size

|

1.8M*1.3M*1.95M

|

1.9M*1.3M*1.95M

|

2.3M*1.4M*1.9M

|

2.58M*1.7M*1.9M

|

2.8M*1.7M*1.95M

|

||||

|

Weight

|

1800KG

|

2100KG

|

2500KG

|

3000KG

|

3800KG

|

||||

Empty can depalletizer

Inline can rinser / can washing machine

The inline can rinser is used to clean the empty cans by clean water before filling, we can add this can rinser in the beginning

of filling line. The twist cages are customized with your sample cans. As long as the height and diameter of your cans are different, you need to buy the extra set twist cages to change.

of filling line. The twist cages are customized with your sample cans. As long as the height and diameter of your cans are different, you need to buy the extra set twist cages to change.

Isobaric pressure / counter pressure filling system

“MIC” Isobaric pressuring filling does not create foaming during fill, unless beer is above 40°F. Counter Pressure filling leaves 1.27CM headspace, required by can manufacturers for product expansions and potential warming during distribution. Our machine will not foaming and it can keep low DO in the cans. Counter pressuring filling does not create foaming during filling process. Adopts high precision buffing process and food grade 304 stainless steel liquid tank. It will equipped with CIP connector as customer's demand.

Liquid nitrogen doser

Normally, as for cold brew coffee, fruit juice and herbal tea filling, we will suggest our

customer to add this liquid nitrogen doser to work with canning machine. In order to extend its shelf life and make sure it tastes good. It also makes the aluminum cans fuller and less prone to deformation.

customer to add this liquid nitrogen doser to work with canning machine. In order to extend its shelf life and make sure it tastes good. It also makes the aluminum cans fuller and less prone to deformation.

Aluminum lid seaming system

The “MIC” system is a mechanism actuated,

cam-driven seamer with easily adjustable rollers that allow for precise adjustment to from seams that are within can-maker

specifications. Seams are formed in under only a second, faster than any other system in its class. Through two past decade’s

technology innovation and optimization, the result is revolutionary.

cam-driven seamer with easily adjustable rollers that allow for precise adjustment to from seams that are within can-maker

specifications. Seams are formed in under only a second, faster than any other system in its class. Through two past decade’s

technology innovation and optimization, the result is revolutionary.

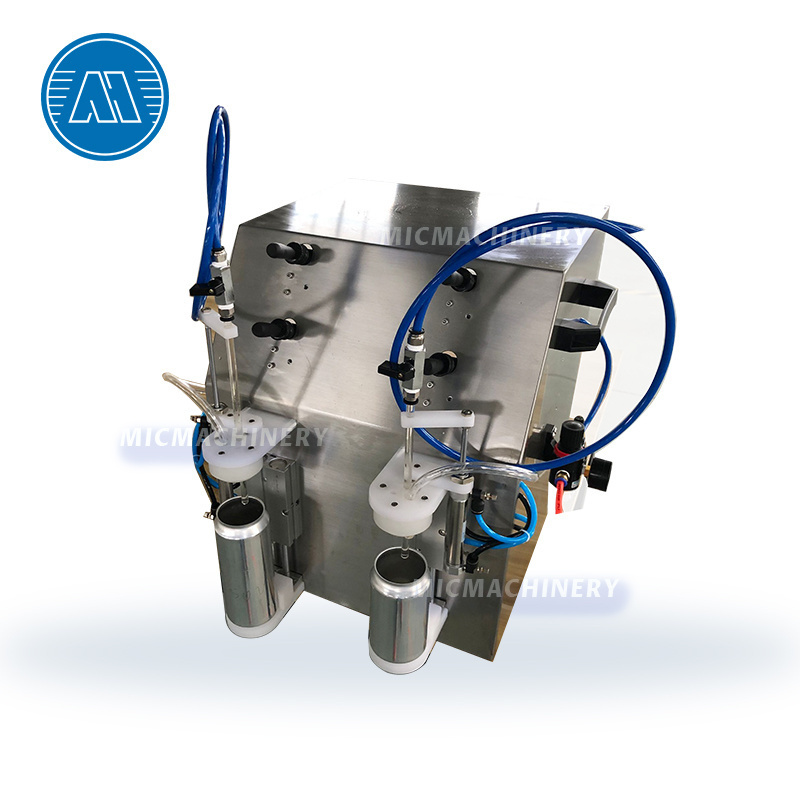

Semi automatic beer filling machine

Put the can on the tray, turn the start button and the machine will start filling automatically. This filling machine is equipped

with reflux device, you do not have to worry about filling liquid will flow out of the cans, if beyond the set page will flow to

the material recycling box, will not waste materials.

with reflux device, you do not have to worry about filling liquid will flow out of the cans, if beyond the set page will flow to

the material recycling box, will not waste materials.

Manual beer sealing machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal

device rotates at high speed and spins the cap efficiently.

device rotates at high speed and spins the cap efficiently.

Hot Searches