- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

3years

-

Place of Origin:

-

Zhengzhou, China

-

Brand Name:

-

HALNN

-

Model Number:

-

vbmt 160402 VBMT160404

-

Product name:

-

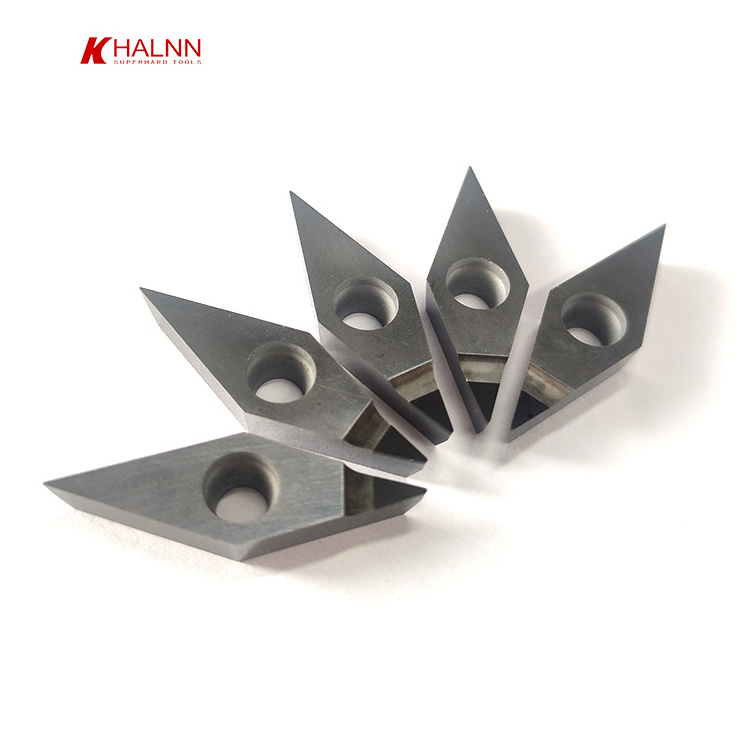

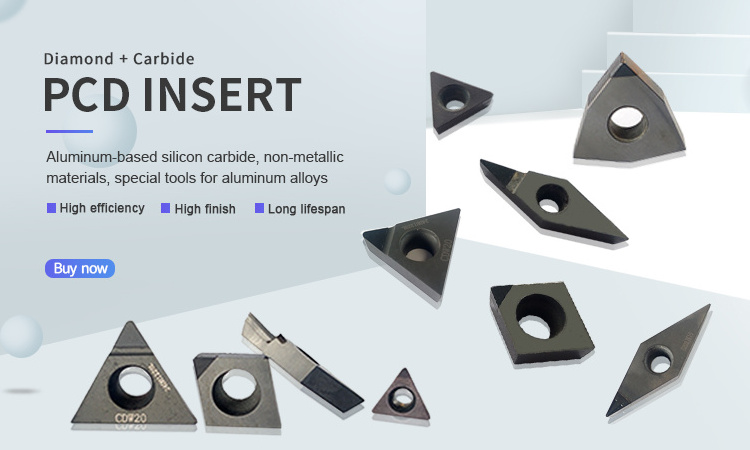

PCD inserts

-

Advantage:

-

Wear Resistance Impact resistance,Good stability

-

Processing hardness:

-

Aluminum/Copper and Alloys

-

Condition:

-

Continuous cutting

-

Processing Material:

-

Aluminum, copper and alloys, non-ferrous metals

-

Application:

-

Wheels, Phone Cases, Engine Blocks

-

Service:

-

Provide customized services

-

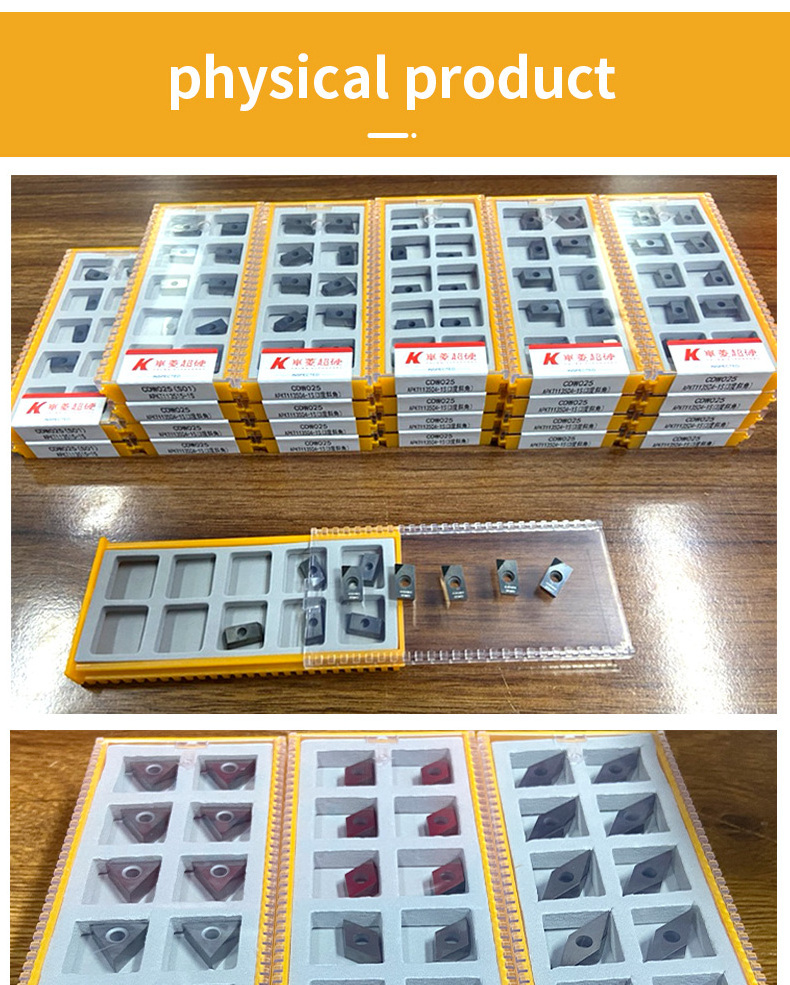

Package:

-

10pcs/plastic Box

-

Delivery time:

-

7days

Quick Details

-

Use:

-

Turning Tool

-

Hardness:

-

HV3100~3600

-

Coating:

-

Uncoated

-

Warranty:

-

3years

-

Place of Origin:

-

Zhengzhou, China

-

Brand Name:

-

HALNN

-

Model Number:

-

vbmt 160402 VBMT160404

-

Product name:

-

PCD inserts

-

Advantage:

-

Wear Resistance Impact resistance,Good stability

-

Processing hardness:

-

Aluminum/Copper and Alloys

-

Condition:

-

Continuous cutting

-

Processing Material:

-

Aluminum, copper and alloys, non-ferrous metals

-

Application:

-

Wheels, Phone Cases, Engine Blocks

-

Service:

-

Provide customized services

-

Package:

-

10pcs/plastic Box

-

Delivery time:

-

7days

Product Overview

Halnn PCD Inserts

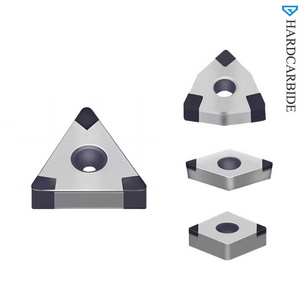

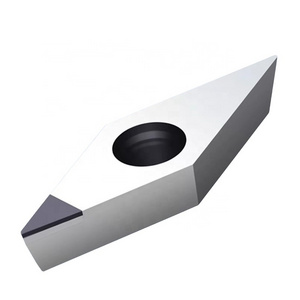

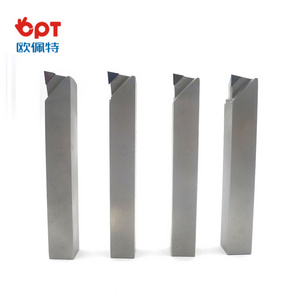

Halnn Superhard offers PCD inserts, PCD chipbreaker inserts, PCD milling cutters, PCD drills, diamond coated tools, etc., made from PCD inserts (cut from PCD blanks) and carbide substrates. Use virgin tungsten carbide material as the substrate. Use raw materials of 99.95% or higher purity to ensure the performance of the PCD tool matrix. It has the advantages of high efficiency, high surface quality, high precision, high cost performance and strong versatility.

PCD inserts are used for machining a wide range of materials such as non-ferrous metals such as aluminum, aluminum alloys, copper, copper alloys, tungsten carbide, aluminum-based silicon carbide, reinforced plastics, rubber, graphite, composite materials, carbon fibers, glass fibers, composite ceramics Wait....

FEATURES AT A GLANCE

* Excellent wear resistance

* Long tool life

* High working efficiency

* Chipbreaker PCD inserts provide excellent chip breaking

* Grinding and chip replacement service available

Turning

Milling

Drilling

PRODUCT SPECIFICATIONS

|

Grade

|

Granularity(μm)

|

Characteristics

|

Application

|

|

CDW850

|

Submicron

|

Ultra-fine grain structure, strong edge sharpness and edge durability

|

High precision machining, mirror surface machining, suite for aluminum alloy that required high on the chipping performance,

mainly used for machining composites |

|

CDW002

|

2μm

|

High cobalt content, Good electrical machine performance, excellent toughness, Good roughness machining, more convinent for

complec tool processing |

Mainly used for engraving milling cutters and turning inserts, for composite materials and silicon-aluminum alloy machining tools.

|

|

CDW005

|

5μm

|

Excellent electric spark and machinability, good toughness, wear resistance and edge quality

|

It suits for good surface quality processing, mainly used for machining PMMA, Silicion alloy and metal cell phone shell outlin.

|

|

CDW010

|

10μm

|

Universal PCD Grade, good toughness and high abrasive resisitance

|

Suit for single tool for rough machining, especially for wood molding, medium and low silicon aluminum alloy parts (such as

piston). |

|

CDW025

|

25μm

|

High wear resistance and edge quality

|

Suit for high Silicion Aluminum alloy, MMC, Tungsten carbide and ceramic, graphite,wear resistant parts.

|

|

CDW302

|

2~30μm

|

Mixed 2μm and 25μm,good wear resistance and edge quality and edges strength

|

It mainly used for machining MMC, high Silicion Aluminum calloy, other application.

|

Product Paramenters

|

Component Materials

|

|

Recommend PCD Grade

|

|

|

|

Cutting Condition

|

|

|

||||||

|

|

|

|

|

|

|

Vc(m/min)

|

Fr(mm/r)

|

ap(mm)

|

||||||

|

Aluminum alloy

|

4-8%Si

|

CDW010

|

CDW302

|

CDW005

|

CDW850

|

100-5000

|

0.03-0.5

|

0.1-3.0

|

||||||

|

|

9-13%Si

|

CDW010

|

CDW302

|

|

CDW850

|

100-3000

|

0.03-0.5

|

0.1-3.0

|

||||||

|

|

>13%Si

|

CDW010

|

CDW302

|

CDW025

|

CDW850

|

100-2500

|

0.03-0.4

|

0.1-2.5

|

||||||

|

Copper alloy

|

Copper, zinc, brass

|

CDW010

|

CDW302

|

CDW025

|

CDW850

|

100-1000

|

0.03-0.3

|

0.1-3.0

|

||||||

|

Titanium alloy

|

|

CDW850

|

CDW005

|

|

|

100-200

|

0.05-0.2

|

0.1-2.0

|

||||||

|

Tungsten Carbide

|

Co < 16%

|

CDW302

|

CDW025

|

CDW010

|

|

15-40

|

0.1-0.25

|

0.1-1.0

|

||||||

|

|

Co > 16%

|

CDW302

|

CDW025

|

CDW010

|

|

10-30

|

0.03-0.1

|

0.05-0.3

|

||||||

|

Reinforced plastic

|

|

CDW010

|

CDW302

|

CDW025

|

CDW002

|

100-1000

|

0.05-0.3

|

0.1-2.0

|

||||||

|

Graphite

|

|

CDW302

|

CDW025

|

CDW010

|

|

100-600

|

0.1-0.5

|

0.05-2.0

|

||||||

|

Metal matrix composites

|

A1/10-20%Si

|

CDW302

|

CDW025

|

CDW010

|

|

300-600

|

0.1-0.4

|

0.2-1.5

|

||||||

|

Composite

|

Carbon Finber

|

CDW302

|

CDW025

|

CDW010

|

|

200-2000

|

0.05-0.3

|

0.1-3.0

|

||||||

DETAILS IMAGES

SALES AND SERVICE NETWORK

Hot Searches