- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

007

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Usage:

-

Widely

-

Mold Life:

-

500000 Shots

-

MOQ:

-

1pcs/set

-

Surface treatment:

-

Polish. Etched. Texture

-

Colors:

-

Available

-

Packing:

-

Plastic Bag+Carton Box

-

Drawing Format:

-

3D.STP. STEP . IGS . PRT . X_T

-

Keyword:

-

plastic injection mold

-

Service:

-

OEM\ODM

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DT

-

Model Number:

-

007

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Usage:

-

Widely

-

Mold Life:

-

500000 Shots

-

MOQ:

-

1pcs/set

-

Surface treatment:

-

Polish. Etched. Texture

-

Colors:

-

Available

-

Packing:

-

Plastic Bag+Carton Box

-

Drawing Format:

-

3D.STP. STEP . IGS . PRT . X_T

-

Keyword:

-

plastic injection mold

-

Service:

-

OEM\ODM

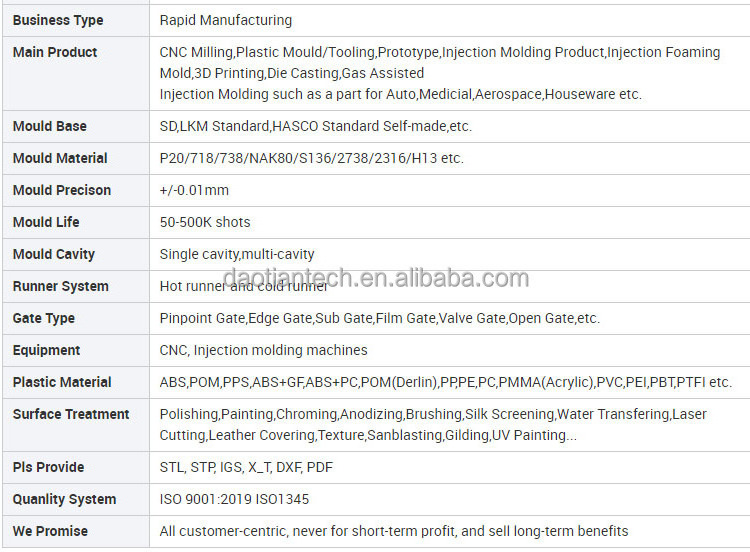

Product Description

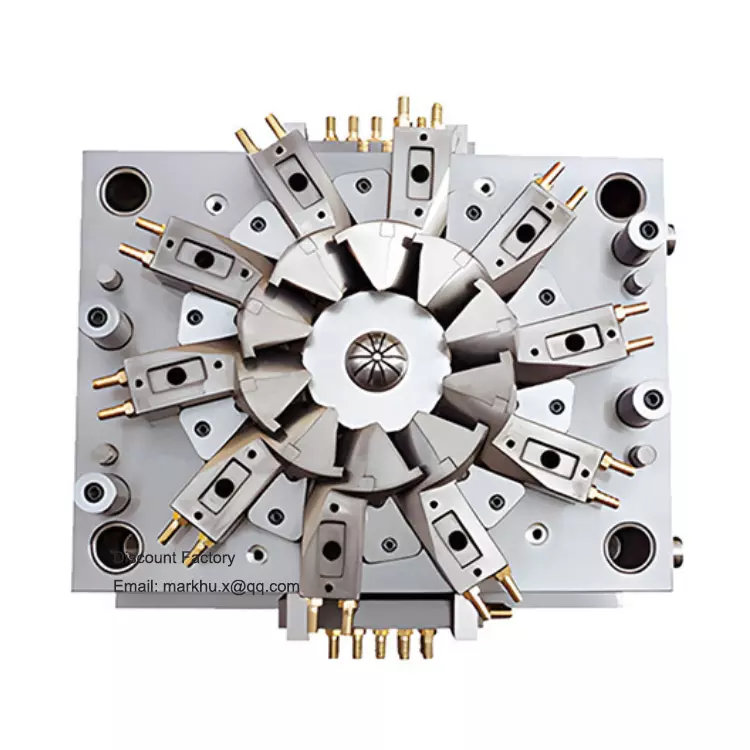

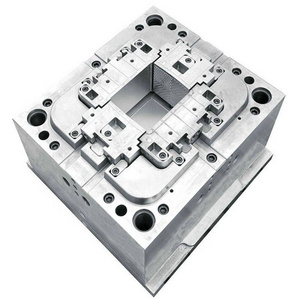

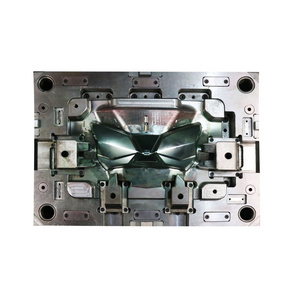

Custom Injection Cover Mold Prototype Shell Molding Plastic School Chalk Mould

There are many factors that affect injection mold structure and mold systems, mainly including the following aspects:

1. Cavity layout. The number and arrangement of cavities shall be determined according to the geometric structure of plastic parts, dimensional accuracy requirements, batch size, mold manufacturing difficulty, mold cost, etc.

2. Determine the parting surface. The position of parting surface shall be conducive to mold processing, exhaust demoulding and molding operations to ensure the surface quality of plastic parts.

3. Determine the pouring system (the shape, position and size of the main runner, runner and gate) and the exhaust system (the method of exhaust, the position and size of the exhaust slot).

4. Select the ejection method (ejector rod, pipe jacking, push plate, combined ejection), and determine the side concave treatment method and core pulling method.

5. Determine the cooling and heating methods, the shape and position of the heating and cooling groove, and the installation position of the heating element.

6. According to the injection mold material, strength calculation or empirical data, determine the mold part thickness, overall dimensions, overall structure and all connection, positioning and guide parts positions.

7. Determine the structural form of main molding parts and structural members.

8. Considering the strength of each part of the mold, calculate the working dimensions of the molded parts.

FAQ

Q1: Are you a trading company or factory?

A: We are direct factory with more than 100 employees as well approximate 3,500 square meters workshop area, in Shenzhen, China. Factory's price is lower,welcome to compare

Q

2: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/permonth/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q4: Do you provide samples? Is it free or extra?

A: Yes we offer free sample but do not afford the shipping cost.

Q5: ls your company currently participating in any Customer Certification Program?

A: 3C certification, REACH,ROHS,PRO65.

Q6: Do you provide assembly service?

A: We offer products design and 3D print service, we have 15 injection machines and 2 assembly lines, we can provide production run and assembly service.

Q7: How do you provide after-sales service?

A: We provide after-sales service within two years after per

customer receives the mold. If the mold is damaged within two years, we can send the new replacement mold fittings for free.

customer receives the mold. If the mold is damaged within two years, we can send the new replacement mold fittings for free.

Best Selling

Hot Searches