- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

34 kN

-

Theoretical Shot Volume(cm³):

-

163 cm³

-

Injection Rate (g/s):

-

78 g/s

-

Injection Weight (g):

-

145 g

-

Screw diameter (mm):

-

36 mm

-

Weight (KG):

-

3000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

BJ90-S6/V6

-

Brand Name:

-

Powerjet

-

Power (kW):

-

6 kW

-

BRAND:

-

Powerjet

-

Model:

-

BJ90-V6/S6

-

Product name:

-

Plastic Products Injection Molding Machine

-

After-sales Service Provided:

-

Online support

-

Motor:

-

Variable Pump/SERVO motor

-

Machine weight:

-

3 ton

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Small Plastic Product Making Machine

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

360mm

-

Distance between Tie Bars(Height)(mm):

-

360mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

34 kN

-

Theoretical Shot Volume(cm³):

-

163 cm³

-

Injection Rate (g/s):

-

78 g/s

-

Injection Weight (g):

-

145 g

-

Screw diameter (mm):

-

36 mm

-

Weight (KG):

-

3000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

BJ90-S6/V6

-

Brand Name:

-

Powerjet

-

Power (kW):

-

6 kW

-

BRAND:

-

Powerjet

-

Model:

-

BJ90-V6/S6

-

Product name:

-

Plastic Products Injection Molding Machine

-

After-sales Service Provided:

-

Online support

-

Motor:

-

Variable Pump/SERVO motor

-

Machine weight:

-

3 ton

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Small Plastic Product Making Machine

Products Description

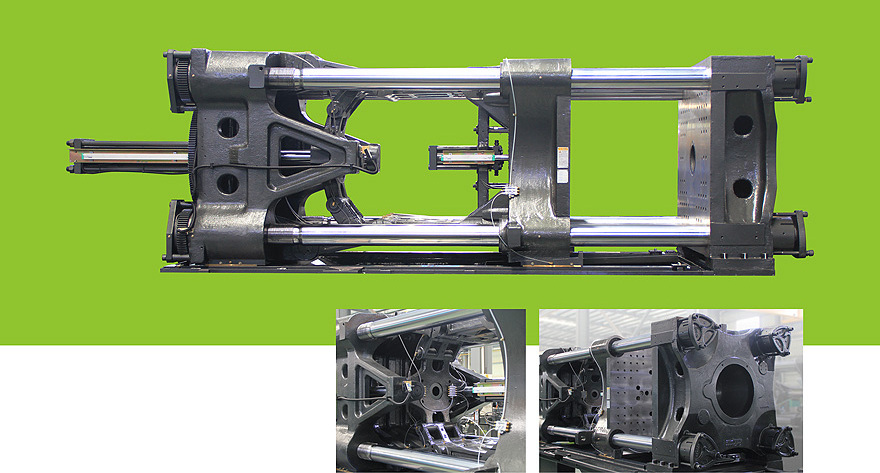

CLAMPING UNIT

Center-pressing toggle structure design, high clamping force, high rigidity, low deformation, production fast and stable.T-slot platen, convenient and fast mould change.

S6 Servo motor

With the adoption of servo control system, the injection pressure & speed 15 under closed loop controlled, and the stability and repeatability can be achieved.

V6 Variable Pump

Perfect combination between computer and high efficient proportional plunger variable pump saves electricity by 25%-50%. The economic efficiency is high.

Comparing with the hydraulic machine, S6 series can save more 50% of the power. Comparing with full electrical machine, energy saving is more obviously seen during pressure hold & cooling stage.

Imported top grade hydraulic components

High precision oil filter and full flow bypass oil

filter

Screw is

driven by low speed & big torque hydraulic motor

Finite element analysis is used on the structure of

mould plates So that the structure of mould plate

is more logical,stronger and higher fatigue resistance.

Automatic dosing lubrication system guarantees mould clamping mechanism to be more stable and reliable.

High precision electric meter is used to

control position. The control precision is

+0.1mm.

Mechanical and double electric interlock

protection devices guarantee the safety

of the operators. (Machine above BJ400 is equipped with hydraulic safety device. )

Wear resistant hard chromium plated tie

bar is featured

with high-tensile and high

strength.

Hydraulic motor with centering gear mould

adjusting system makes mould adjusting

system to be better.

Product Paramenters

|

DESCRIPTION

|

DESCRIPTION

|

UNIT

|

BJ90-V6/S6

|

|

|

CLAMPING UNIT

|

Clamping force

|

KN

|

900

|

|

|

|

Opening stroke

|

mm

|

320

|

|

|

|

Max.datlight

|

mm

|

680

|

|

|

|

Platen size

|

mm

|

540*540

|

|

|

|

Space between bars

|

mm

|

360*360

|

|

|

|

Max.mold height

|

mm

|

360

|

|

|

|

Min.mold height

|

mm

|

130

|

|

|

|

Ejector stroke

|

mm

|

100

|

|

|

|

Ejector force

|

KN

|

34

|

|

|

INJECTION UNIT

|

Screw diameter

|

mm

|

30

|

|

|

|

Screw L/D Ratio

|

L/D

|

20.7

|

|

|

|

Injection Pressure

|

MPa

|

266

|

|

|

|

Shot volume

|

cm3

|

113

|

|

|

|

Screw stroke

|

mm

|

101

|

|

|

|

Screw speed

|

rpm

|

174

|

|

|

POWER UNIT

|

Hydraulic system Pressure

|

MPa

|

17.5

|

|

|

|

Pump motor power

|

KW

|

11

|

|

|

|

Heater power

|

kW

|

6

|

|

Why Choose Us

Powerjet

has become the booming power in the professional plastic machinery industry.

Since founded in 2000, Powerjet has worked with customers all along. Focusing on every customer need.

Using “innovation plus exemplary case”. surpassing customers needs to realize the win-win cooperation. Its equipment has enjoyed a good reputation both at home and abroad. With the technological accumulation for 20 years. The world’s top technological team has been established. Being market -oriented to constantly innovated and upgrade products, devoting to reduce customers’ operating costs, providing the high-quality, innovative and optimal solution of plastics manufacture.

POWERJET is a high and new technology enterprise of injection molding machine and blow molding machine.

POWERJET PLASTIC MACHINERY co., LTD.

was founded in 2000, the headquarter is located in Foshan high tech Industrial Park, Sanshui, Foshan in Guangdong Province, occupying an area of 130,000 square meters. Advanced equipments like CNC imported from Mitsubishi, OKUMA, DOOSAN are introduced, POWERJET is a high and new technology enterprise of R &D, manufacturing, sales, after-sales service of injection molding machine and blow molding machine.

To ensure the timely product delivery with the extremely fast production cycle. And ensure the qualified product. We integrate the craftsmanship spirit into each detail. Passing the international ISO and CE certificates and Korean KCS certificate. To freatly ensure the low energy consumption, high precision and reliability of Powerjet products.

SALES AND SERVICE NETWORK

We have established the global marketing network. To deliver the value of Powerjet injection molding machine and extrusion blow molding machine to over 100 countries area. Multiple senior managers and business elites worldwide. Become the trustworthy partners. Provide the most thoughtful service and fastest user support for you constantly. sincerity for you.

Customer Photos

FAQ

Q1: Are you a manufacturer or trading company?

A1: We are a factory for plastic machines. Over 20 Years Experience In Manufacturing Injection Molding Machine And Blow Molding Machine.

Q2: Delivery time

A2: Normally Machine Delivery from the factory in 0-60 days after receiving the down payment. (During Chinese Public Holidays like National Day or Chinese New Year, the delivery time should be 10-30days longer accordingly).

Q3: Where is your factory located?

A3: Our factory is located in No.5 Chuangxin Xi Road, Leping Town, Sanshui District, Foshan City, Guangdong Province, China. 1h drive from Guangzhou to our factory. Welcome to visit our factory.

A1: We are a factory for plastic machines. Over 20 Years Experience In Manufacturing Injection Molding Machine And Blow Molding Machine.

Q2: Delivery time

A2: Normally Machine Delivery from the factory in 0-60 days after receiving the down payment. (During Chinese Public Holidays like National Day or Chinese New Year, the delivery time should be 10-30days longer accordingly).

Q3: Where is your factory located?

A3: Our factory is located in No.5 Chuangxin Xi Road, Leping Town, Sanshui District, Foshan City, Guangdong Province, China. 1h drive from Guangzhou to our factory. Welcome to visit our factory.

Hot Searches