- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 410V 220v 440v

-

Dimension(L*W*H):

-

5.9mx5.5mx4.5m

-

Weight:

-

6000 kg

-

Warranty:

-

1year

-

Marketing Type:

-

Hot product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ISO CE

-

Cutting Material/Type:

-

Cr12Mov,Heat treatment

-

Total Motor Power:

-

16.7KW

-

Step of rollers:

-

13+2

-

Proper Span:

-

≤38m

-

Working Speed:

-

Straight Sheet 15m/min

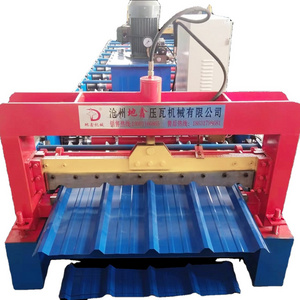

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-15m/min

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 410V 220v 440v

-

Dimension(L*W*H):

-

5.9mx5.5mx4.5m

-

Weight:

-

6000 kg

-

Warranty:

-

1year

-

Marketing Type:

-

Hot product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ISO CE

-

Cutting Material/Type:

-

Cr12Mov,Heat treatment

-

Total Motor Power:

-

16.7KW

-

Step of rollers:

-

13+2

-

Proper Span:

-

≤38m

-

Working Speed:

-

Straight Sheet 15m/min

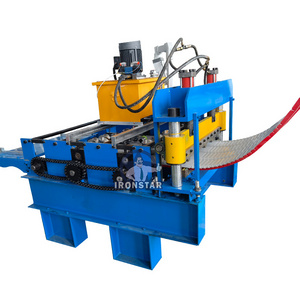

NO-GIRDER ARCH ROOF QSPAN BUILDING MACHINE/BEAMLESS STEEL ARCH ROOK SPAN MACHINE

Specifications

No girder large span curving color Sheet Roll Forming Machine

1.reasonable price

2.high efficientcy

3.best quality

No girder large span curving color Sheet Roll Forming Machine

Why Do People Choose Arch Roof Steel Buildings?

Fast And Easy DIY Assembly

Durable Construction With Galvalume Steel

High Quality Grade

Affordable, Factory Direct Pricing

What Is The Arch Roof Building Machine Widely Used For?

1.Conventional Building Appearance

2.Ideal For Backyard Applications, Including Workshops Garages, And Equipment Storage

3.Economical And Easy Construct

Working flow:

De - coiler-----feeding-----roll forming----cutting-----curving----output table

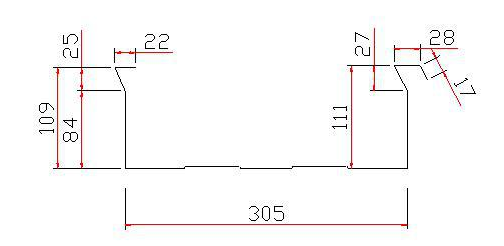

Technical description:

|

Size |

Forming and Curing |

9500mmx2270mmx2400mm |

|

Total weight |

About 10 T |

|

|

Cutting Material/Type |

Cr12Mov,Heat treatment |

Electrical |

|

Total Motor Power |

16.7KW |

|

|

Forming Power 5.5KW |

|

|

|

Bending Power 6 KW |

|

|

|

Cutting Power 3KW |

|

|

|

Sewing Power 2.2KW |

|

|

|

Meterial of rollers |

45#steel,chromed and quenched HRC58-62 |

|

|

Material of shafts |

45#steel,adjusted |

|

|

Step of rollers |

13+2 |

|

|

Proper Span |

≤38m |

|

|

Working Speed |

Straight Sheet |

15m/min |

|

Arch Sheet |

13m/min |

|

|

Sewing |

10m/min |

|

|

Electric Standard |

380V/60HZ/3PHASES |

|

|

Controlling System |

PLC (Siemens) |

|

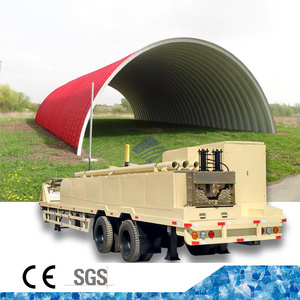

Installation

Technology

On site Production and installation of Self Supported curved roofing without any structure, enables faster and leak proof roofing systems, thus ensuring utmost flexibility in work and design.

Easy & Quick Installation

As the production is carried out on site, the installation will be faster , take an example, 1500 square meters area in just 12 hours, enabling to finish the project in very quick time.

Durability and Resistance to Corrosion

Galvanized and pre-coated steel coil give corrosion resistance and superior heat reflectivity. Galvanized Steel reflects a high percentage of heat and can withstand in any weather conditions without surface discoloration. It is of High tensile Steel and comes in spectrum of colors, to enhance the appearance, life and value of the building; specially designed sewing machines eliminate use of fasteners and thus ensure 100% leak proof roofing.

Payment Terms

|

Payment type |

30% T/T prepaid and balance should be paid before loading |

|

Delivery time |

7 days after rece i ving advance payment |

|

Guarantee period |

18monthes free service/ pay service all the machine life |

|

Installation and training |

If buyers visit our factory and check the machine, we will teach you how to install and use the machine,

and also train your workers/technician face to face.

to teach you to install and operate.

please arrange board and lodging and other necessary things. |