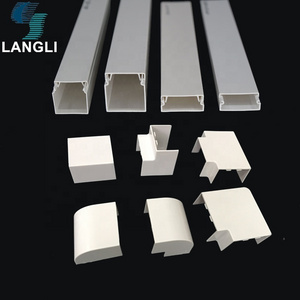

- Product Details

- {{item.text}}

Quick Details

-

Length:

-

2m(6.5ft),2.44m (8 ft), 3m (10 ft)

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

Model Number:

-

CT

-

Side Rail Height:

-

12, 15, 25, 50, 75, 100, 150, 200 mm

-

Max. Working Load:

-

According to size

-

Product Name:

-

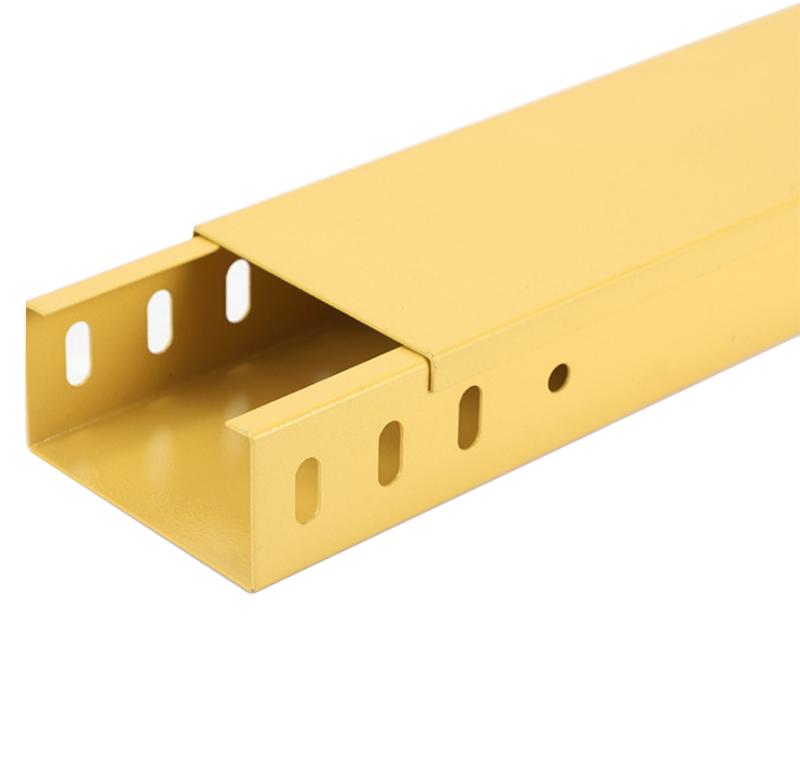

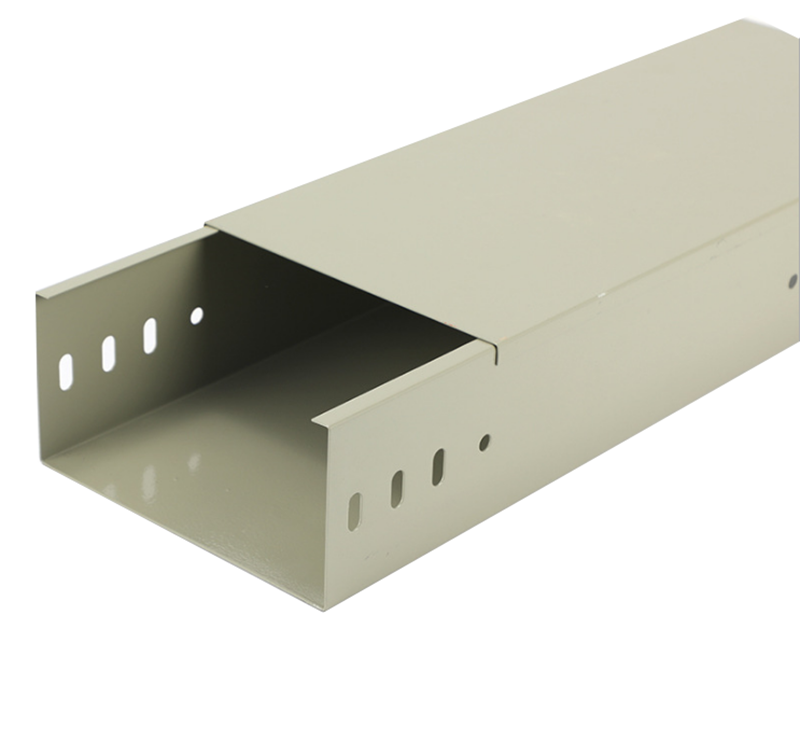

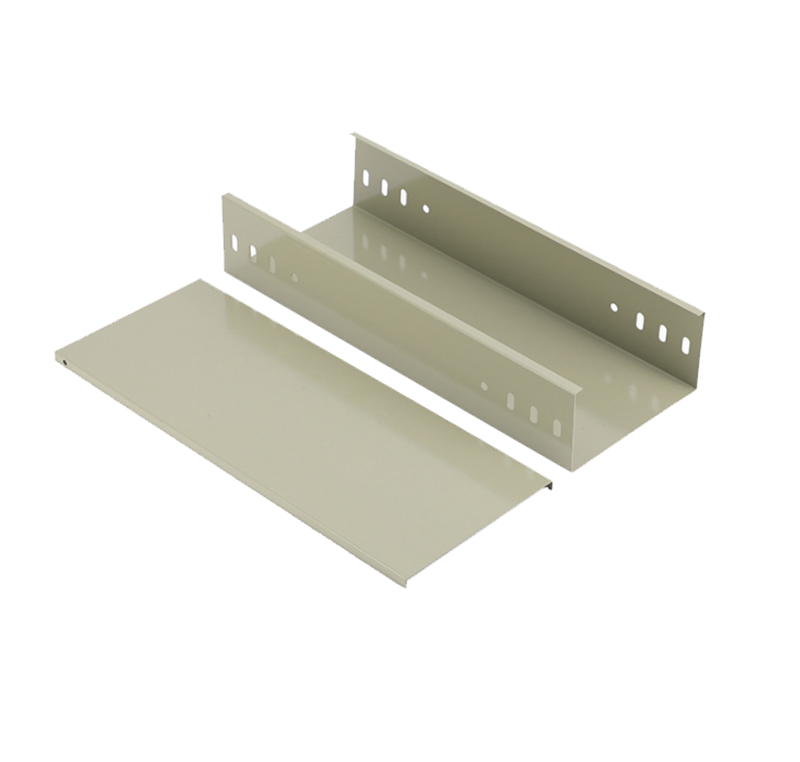

Cable Trunking

-

Certificates:

-

ISO CE

-

Surface Finish:

-

Electro-Galvanized Finish.HDG. POLISH

-

Thickness:

-

0.6-3.0mm

-

Application:

-

Mining

-

Color:

-

Customized

-

Feature:

-

Corrosion ResistanceGalvanized Cable Trunking

-

Raw material:

-

Q195,Q235 SS304 SS316 SS316L

-

Guarantee:

-

According to your requirements

-

Safe work loading:

-

BS EN 61537:2007 Cable Ladder Tray

Quick Details

-

Type:

-

Solid Through

-

Material:

-

Steel,stainless steel,aluminum

-

Width:

-

50, 100, 150, 300, 450, 600, 900 mm

-

Length:

-

2m(6.5ft),2.44m (8 ft), 3m (10 ft)

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

Model Number:

-

CT

-

Side Rail Height:

-

12, 15, 25, 50, 75, 100, 150, 200 mm

-

Max. Working Load:

-

According to size

-

Product Name:

-

Cable Trunking

-

Certificates:

-

ISO CE

-

Surface Finish:

-

Electro-Galvanized Finish.HDG. POLISH

-

Thickness:

-

0.6-3.0mm

-

Application:

-

Mining

-

Color:

-

Customized

-

Feature:

-

Corrosion ResistanceGalvanized Cable Trunking

-

Raw material:

-

Q195,Q235 SS304 SS316 SS316L

-

Guarantee:

-

According to your requirements

-

Safe work loading:

-

BS EN 61537:2007 Cable Ladder Tray

OEM & ODM Services

15 Years Experience

Per Day 25 Kilometers

CE ISO 9001 SGS

One To One Service

Multiple Delivery

Product Details

|

fire-proof cable tray

|

fire-resistant cable tray

|

|

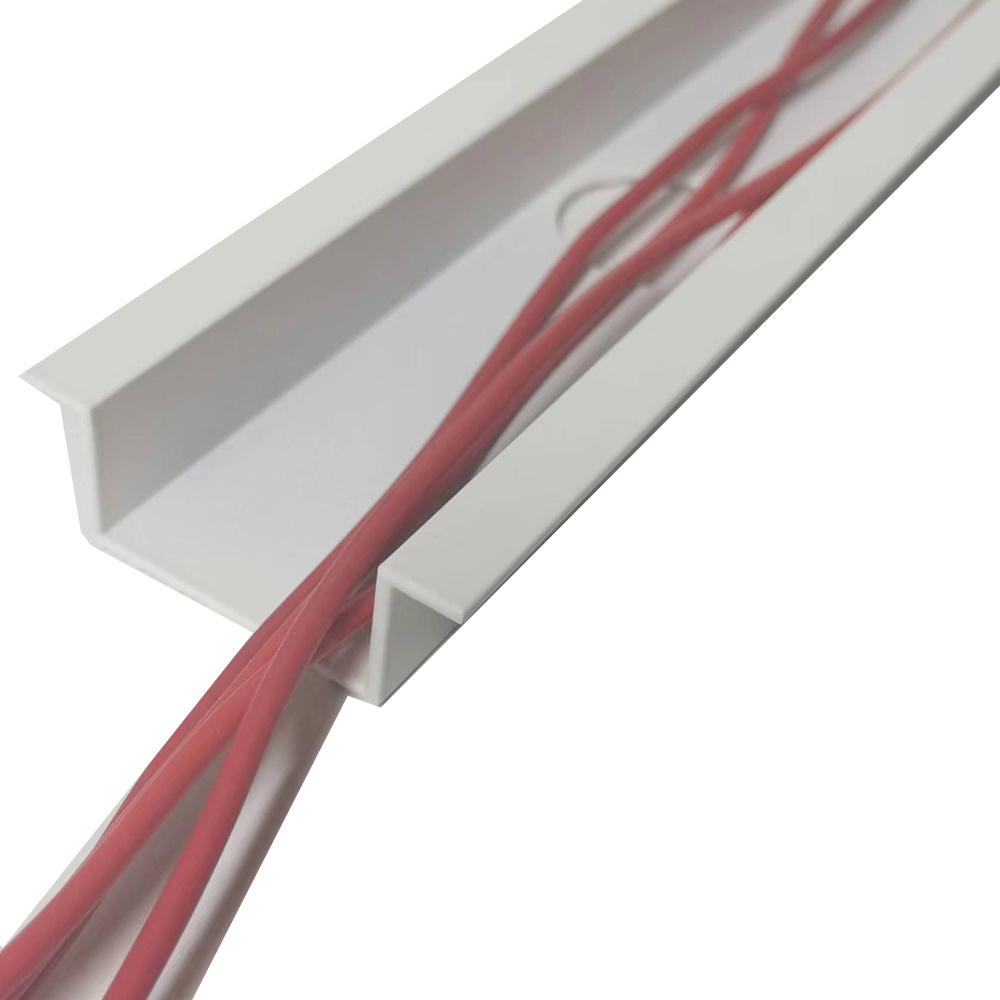

Fire proof cable bridge: the shell of ordinary cable tray or cable tray with fire smoke spreading is added with fireproof

partition layer. Some shells are coated with fire retardant coating, which can transmit heat to the interior of the fire within the specified time. The fireproof cable tray can operate normally, and the fire burning temperature reaches about 800 degrees. The fire resistance time of the fire-proof cable tray is 30 minutes, 40 minutes and 60 minutes respectively.

The fire-proof cable tray is made of steel shell, double-layer fire-proof cover plate and inorganic fire-proof trough box. The

average thickness of thermal insulation layer is 25 mm. The double-layer cover plate ventilates and dissipates heat, and the fire-proof coating is sprayed inside. When the fire-proof cable tray encounters fire, the coating expands, blocks the heat dissipation hole, and protects the cable in the box. The fireproof performance of the unorganized fire-proof box has been tested by the national fixed fire resistance Inspection Center for 60 minutes, The cable has no damage. The support structure is good, which can effectively fix the inorganic fireproof trough box |

The shell and insulation layer of the fire-resistant bus cable tray are made of fireproof materials with high-temperature resistance ≥ 1100 ℃ and insulation materials with high-temperature resistance ≥ 300 ℃. The fire-resistant time of fire-resistant

cable tray includes 60 minutes, 90 minutes, 120 minutes and 180 minutes. When the temperature reaches 920-1050 ℃, it will burn, and the full load operation can reach more than 8 hours.

The thickness of fire retardant paint should be greater than or equal to 1 mm, which is the general effect of fire retardant

paint. There are also cheap and expensive differences, and the expensive effect is better |

|

Product Size

|

width 25-900mm

Thickness: 0.8mm-3.0mm

length is cut according to customer's requirements U or C shape with standard AISI, ASTM, GB,BS,EN,JIS,DIN or customer's drawings |

|

Product Material and Surface

|

· Material: carbon steel aluminum stainless steel

· Surface coating: o Galvanized o Hot Dipped Galvanizing o Electrolytic Galvanizing o Powder coating o Neomagnal o Anodizng |

|

Corrosion Rating of Galvanizing

|

For example

Outdoor:Atmospheres with low contamination levels. Mostly rural areas.

Indoor:Unheated buildings with possible condensation, such as warehouses

and sports halls.

Galvanization wear:0,1 μm - 0,7 μm in a year

|

|

Corrosion Rating of Hot Dipped Galvanized

|

For example

Indoor:Production premises with high humidity levels and some impurities in the air, such as food industry facilities. Outdoor:Urban and industrial atmosphere with medium sulphur dioxide levels. Coastal areas with low salinity levels. Galvanization wear:0,7 μm - 2,1 μm in a year Indoor:Chemical industry production plants, coastal shipyards and boatyards. Outdoor:Industrial areas and coastal areas with medium salinity levels.Galvanization wear:2,1 μm - 4,2 μm in a year |

Related Products

About US

Shanghai Qinkai Industrial Co., Ltd. is a company specializing in the production of cable trays, metal wire troughs, support systems and a large number of stamping parts. C-shaped steel, finished support, seismic support, solar support and related accessories. Scientific quality management system, skilled industrial technology, and always adhering to the service concept of customer first.

Shanghai Qinkai Industrial Co., Ltd. is recognized by the industry for its integrity, strength and product quality. Welcome new and old customers to visit, guide and negotiate business.

The processing technology of channel bar is relatively simple

|

Package

|

Standard export seaworthy package,suit for all kinds of transport, or as required.

Water-proof Paper + Edge protection + Wooden Pallets

|

|

Loading Port

|

Tianjin, Xingang Port, Qingdao,Shanghai, Ningbo, or any China Seaport

|

|

Container

|

1*20ft container load Max. 25 Ton, Max. length 5.8m

1*40ft container load Max. 25 Ton, Max. Length 11.8m

|

|

Delivery Time

|

7-15 days or according to the order's quantity

|

Certificate and Inspection

Good Quality Makes Us Different

* All support channel products are produced by ISO9001 or CE certified mill

* All support channel products are EN10204 3.2 Certified

* Non-destructive Testing Report are available if required

* Surface Treatment Report are available if required

* Mechanical Testing Report are available if required

* All support channel products are produced by ISO9001 or CE certified mill

* All support channel products are EN10204 3.2 Certified

* Non-destructive Testing Report are available if required

* Surface Treatment Report are available if required

* Mechanical Testing Report are available if required

Our product application include Industrial buildings and metal structures Such as plant, bridge, ship, agricultural machinery vehicle manufacturing, transmission tower, transport machinery

Customer Praise and Service

Our Service

Pre-sale Service:

1.Samples can be offered with courier fee by buyer's side.

2.Good quality + Factory price + Quick response +Reliable service

3.100% responsible for the quality:all the products are produced by our professional workman and we have a high-work-effect foreign trade team.

4.We have enough stock and can deliver in short time.

5.Customized designs,colors,sizes and logos are welcome,responsiveness to customers' requirements.

After-sale Service:

1.We will count cheapest shipping cost and make invoice to you at once.

2.On time delivery.

3.Provide real pictures of loading container,email you the tracking NO. and help to chase the products until the goods arrive you.

4.24 hours online service,if any question, please contact us at anytime in your convenience.

Contact US:+0086 13774332258

Any problem, please send us a inquiry , our company will try our best to serve you

Hot Searches