- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Acrylic-100% Virgin PMMA Imported

-

Accessories:

-

Air Pump

-

Warranty:

-

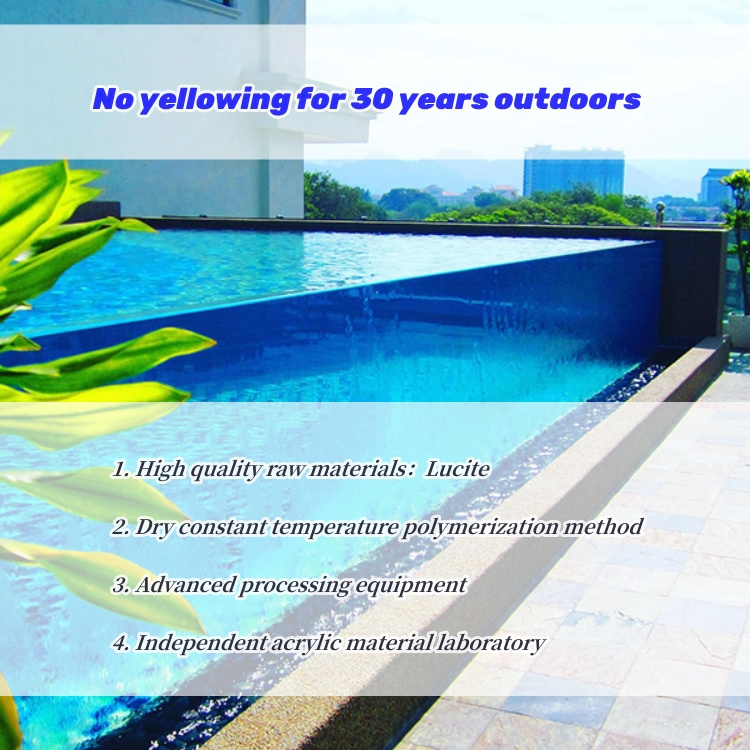

30 years outdoor use non-yellowing

-

Color:

-

Transparent, clear

-

Keyword:

-

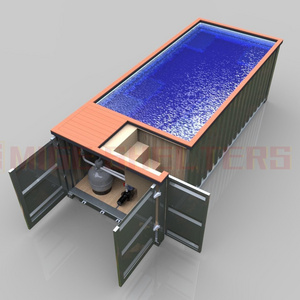

acrylic pool ,Villa Pool , modular pool

-

Diaphaneity:

-

High light transmission(93%)

-

Usage:

-

Construction,building material

-

samples:

-

$0.01 sample available

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUPOOL

Quick Details

-

Model Number:

-

AUPOOL-transparentpool

-

Product Name:

-

Acrylic Transparent Swimming Pool

-

Application:

-

villa ,hotel, school , house backyard , gym pool, aquarium

-

Material:

-

Acrylic-100% Virgin PMMA Imported

-

Accessories:

-

Air Pump

-

Warranty:

-

30 years outdoor use non-yellowing

-

Color:

-

Transparent, clear

-

Keyword:

-

acrylic pool ,Villa Pool , modular pool

-

Diaphaneity:

-

High light transmission(93%)

-

Usage:

-

Construction,building material

-

samples:

-

$0.01 sample available

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUPOOL

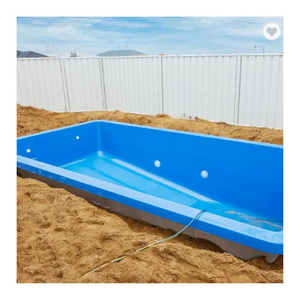

Introducing the Aupool Transparent Clear Acrylic Pool

a stunning swimming pool or aquarium option featuring

a 30mm, 950mm thickness transparent cast PMMA acrylic panel

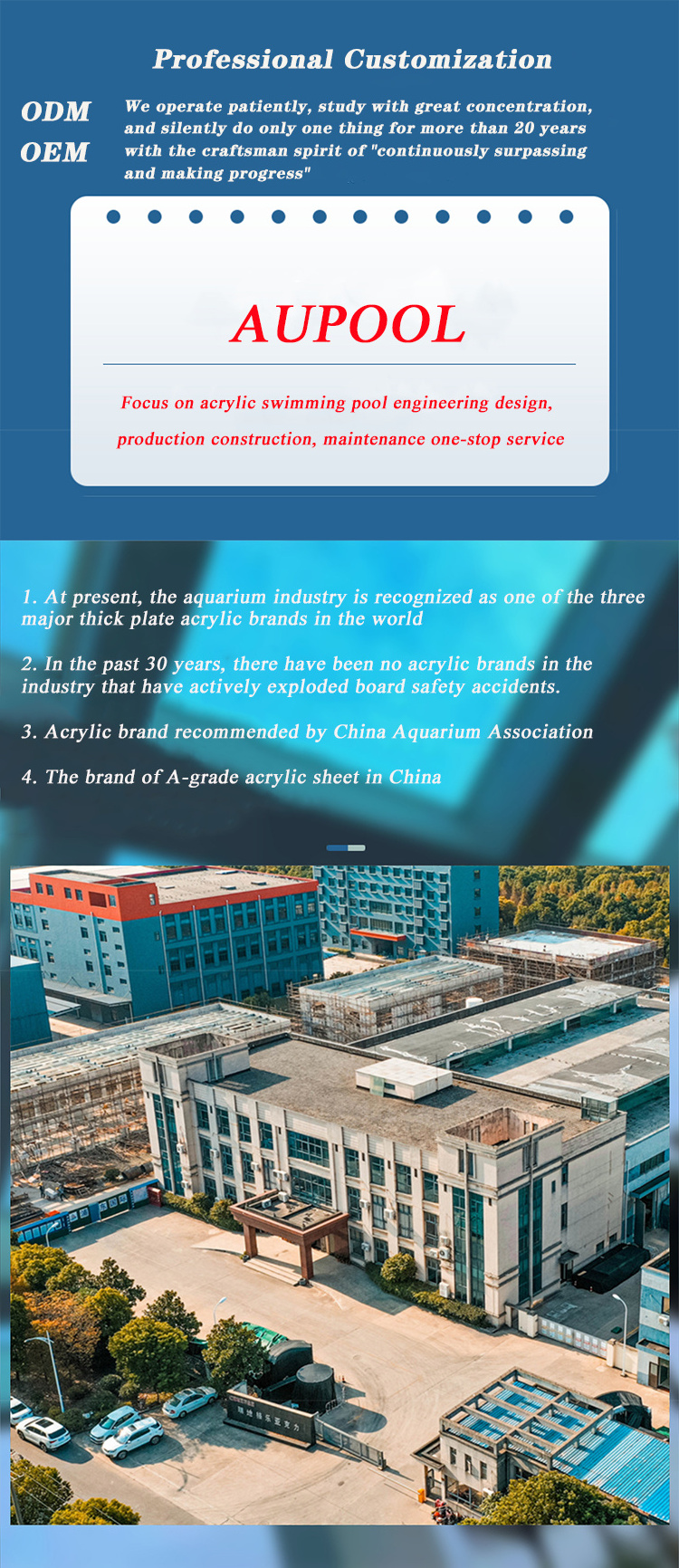

Company Introduction

Product Description

Acrylic thick panel for swimming pool

Why choose us?

Our factory produces AUPOOL, which is one of the world's three largest thick plate acrylic brands and the safest in the aquarium industry, having no active explosion safety accidents in the past 30 years. It is also the only acrylic brand recommended by the China Aquarium Association and capable of producing dry-type constant temperature polymerized acrylic sheets. We have a first-class seamless splicing process and have designed, produced, and constructed China's largest suspended transparent swimming pool and largest suspended transparent veneer. Over 95% of transparent swimming pools in Southeast Asia use our acrylic thick plates. We have served many Chinese billionaires and international brands and provide a large number of actual cases for customers to verify the longevity of our boards, which do not turn yellow, change color, produce turbidity, or lose transparency after long-term use outdoors. We supply the best boards at the most competitive prices.

Specification

|

Property

|

Description

|

|

Material

|

Acrylic (polymethyl methacrylate)

|

|

Transparency

|

High optical clarity, similar to glass

|

|

Thickness

|

Usually 30-150mm

|

|

Strength

|

Stronger than glass, but can scratch or crack

|

|

Maintenance

|

Requires regular cleaning and polishing to prevent scratches

|

|

Resistance

|

Resistant to UV radiation, chemicals, and weathering

|

|

Insulation

|

Good insulation properties, retaining heat better than glass

|

|

Installation

|

Can be custom molded and installed on-site

|

|

Cost

|

Generally more expensive than traditional swimming pool materials

|

|

Aesthetics

|

Provides a unique and modern look for a swimming pool.

|

Detailed Images

Iterative process and advanced equipment

1. AUPOOL uses a dry constant temperature polymerization method in their acrylic sheet casting process, which produces sheets with superior performance compared to other manufacturers' traditional pool bath method. The resulting acrylic sheets have a stable structure.

2. AUPOOL has access to advanced plate processing equipment such as gantry sawing machines and gantry water grinders. Additionally, they have a large drying room equipped with a thermal circulation fan that measures 15 meters in length and 5 meters in width.

3. To ensure the quality of their finished products, AUPOOL has their own independent acrylic material laboratory that utilizes national standard testing equipment. They maintain control over the production process from the source end of sheet production to prevent any substandard products from entering the next process.

Dry thermostatic

polymerizat

ion

High safety factor

Excellent processing performance

Safety Work

How to order

Acrylic panel in pool

1.

Tell us the size.

Tell us your swimming pool length,width and height,water level.It is better have design file.

2.

Draft Design.

By finite element analysis,we sure the thickness of acrylic,we draw design for you.

3.

Production.

We start production,cutting,bonding,bending,polishing,QC and packing,shipping to you

4.

Installation.

We provide you installation guide,our engineer can go to your side to do installation if necessary

2.

Draft Design.

By finite element analysis,we sure the thickness of acrylic,we draw design for you.

3.

Production.

We start production,cutting,bonding,bending,polishing,QC and packing,shipping to you

4.

Installation.

We provide you installation guide,our engineer can go to your side to do installation if necessary

Certificate

Packing&Shipping

How to packing acrylic panels ?

Use EPE to wrap up swimming pools and bathtub;

Use foam to protect the frame of swimming pools and bathtub;

Wooden case could make sure strong protection.

FAQ

Hot Searches