- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15KW/37KW/45KW/90KW/110KW

-

Weight:

-

26000 KG

-

Product name:

-

MVR Evaporator

-

Application:

-

materials concentration

-

Material:

-

316L/2205/304

-

Evaporation Capacity:

-

0.1 to 800ton/h

-

Advantage:

-

Steam Saving

-

Evaporation type:

-

Vaccum Evaporation

-

Vacuum degree:

-

0.098Mpa

-

Evaporation Temperature range:

-

50℃-95℃

-

Evaporating Flask:

-

customized

-

Type:

-

Falling Film MVR Evaporator

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shangu

-

Voltage:

-

220/380/415/440/480V

-

Power:

-

15KW/37KW/45KW/90KW/110KW

-

Weight:

-

26000 KG

-

Product name:

-

MVR Evaporator

-

Application:

-

materials concentration

-

Material:

-

316L/2205/304

-

Evaporation Capacity:

-

0.1 to 800ton/h

-

Advantage:

-

Steam Saving

-

Evaporation type:

-

Vaccum Evaporation

-

Vacuum degree:

-

0.098Mpa

-

Evaporation Temperature range:

-

50℃-95℃

-

Evaporating Flask:

-

customized

-

Type:

-

Falling Film MVR Evaporator

Falling Film MVR Evaporator System for evaporation and crystallization materials concentration vacuum evaporator

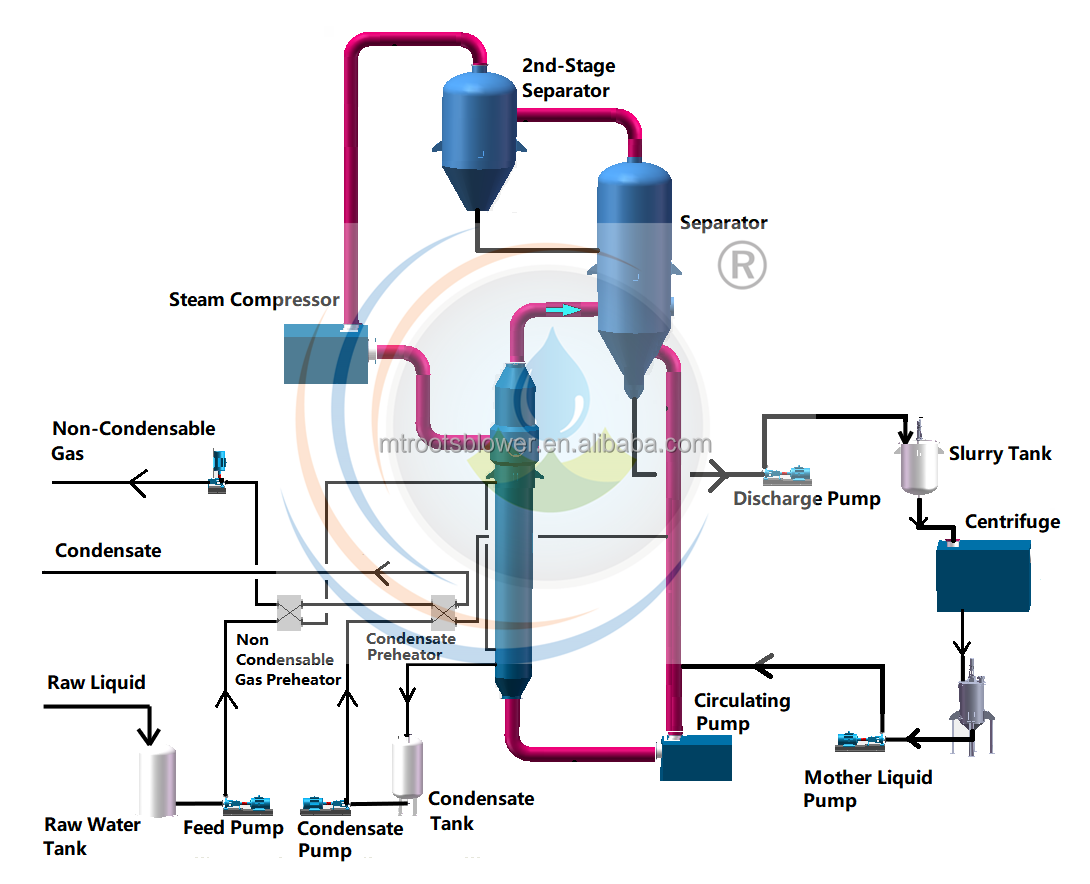

Main Principle

The MVR evaporator uses the secondary steam generated in the evaporator to be mechanically compressed by the compressor, the pressure is increased, the heat is increased, and then the heat exchanger is condensed to fully utilize the latent heat of the steam, except for the start-up operation, the entire evaporation process, the theory There is no need for a single steam, so that the steam that was originally discarded is fully utilized, the latent heat is recovered and the thermal efficiency is improved, and the economy is equivalent to the 30 effect of multi-effect evaporation.

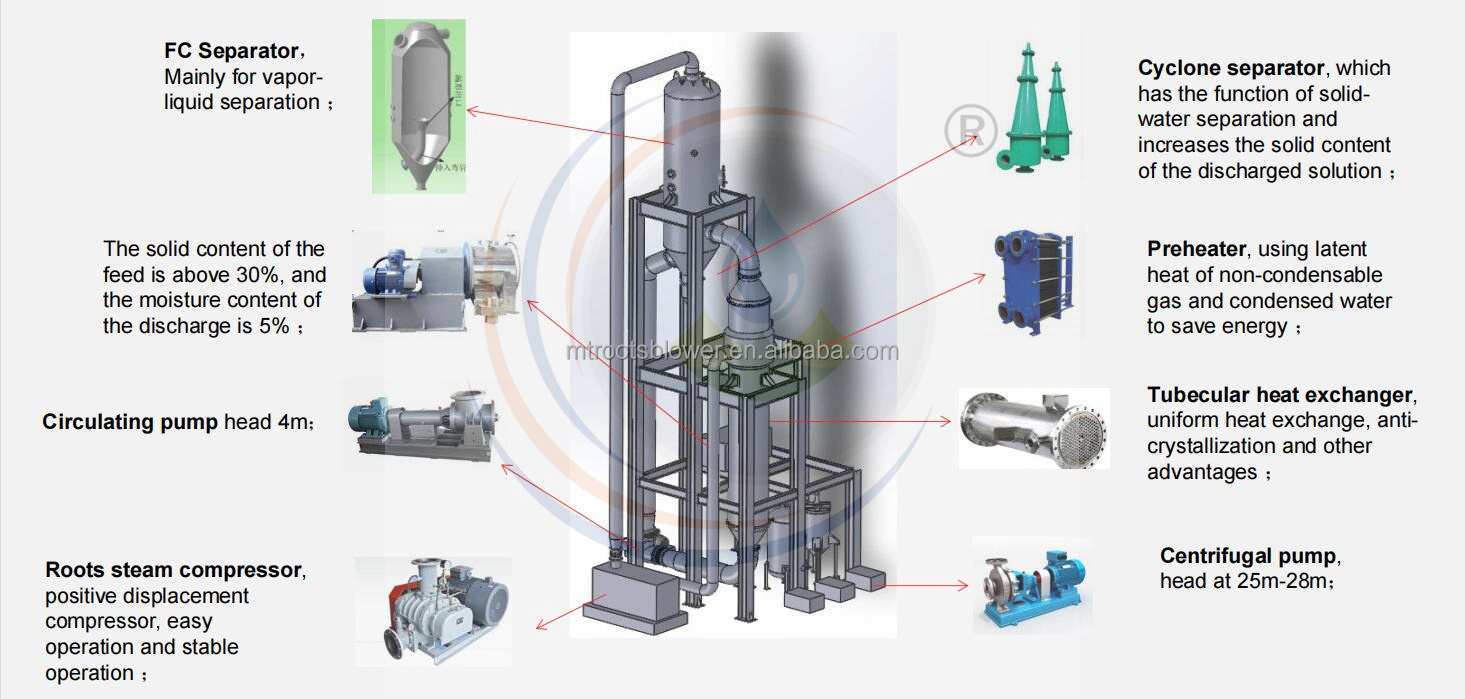

System Composition

The heating system is composed of a heater, a separator, a compressor, a vacuum pump, a circulation pump, an operation platform, an electric instrument control cabinet, a valve, and a piping system.

Main features of the MVR evaporator system

1)MVR energy-saving evaporator technology is currently the most advanced evaporator technology in the world, only a very small amount of raw steam is needed (a small amount of steam is required when starting up, Steam is almost no longer needed in normal operation, which greatly reduces the operating costs of the company and reduces environmental pollution.

2)because the heat source provided by the compressor is much smaller than the conventional evaporator, the temperature difference can be achieved, the product can be greatly improved, Reduce fouling.

3)no condenser or only a small area of condenser, the structure and process is very simple, fully automatic operation, continuous operation, safe and reliable.

4)The equipment is equipped with CIP cleaning pipeline, which can realize local cleaning. The whole set of equipment is easy to operate, no dead angle, high degree of automation and stable operation.

5)The evaporator is evaporated by the material at a low temperature (evaporation temperature 50 ℃ - 95 ℃ ) and is not easy to generate foam. The liquid is uniform and does not run m aterial, not easy to coke, the material heat denaturation is minimal.

6)Although the initial investment quota is high, the return on investment of most projects is generally 1.5 to 2 years, and the maximum is no more than three years.

7)the electricity consumption of one ton of water evaporation is 23-70kw·h.

|

Parameter |

Type |

Reactor |

Single-effect evaporator |

Multi-effect evaporator |

Jet pump |

MVR evaporator |

|

Energy consumption |

High energy consumption, about 1.5 tons of steam is required to evaporate one ton of water |

Energy consumption is high. One ton of steam is theoretically required to save one ton of steam. |

Compared with the increase in efficiency, the energy consumption is correspondingly reduced. |

The traditional multi-effect evaporator is based on one more effect, but requires high-pressure steam to drive |

the most energy-efficient evaporator technology; 20kw/h-70kw/h power consumption |

|

|

Floor space |

small |

small |

big |

big |

small |

|

|

Impact on product quality |

Evaporation products have a long residence time, which seriously affects product quality and color. |

The residence time is short but the temperature difference is high; easy to scale; less impact on product quality. |

Longer residence time, higher temperature difference; easy to scale; Smaller impact on product quality |

Short r esidence time, less impact on product quality, |

short residence time, low temperature difference evaporation; not easy to scale; minimal impact on product quality |

|

|

Energy mode |

Direct heating with coal or diesel oil; or heating with steam. |

Steam heating is required. Steam pipe network is required , Steam is required for boiler heating |

Steam heating is required. Steam pipe network is required , Steam is required for boiler heating |

Steam heating is required. Steam pipe network is required , Steam is required for boiler heating |

Use power, no steam pipe network, full self-closing circulatory system

|

|

|

Self-control degree |

Manual operation |

Semi-automatic control |

Full automatic control operation , continuous evaporation |

Full automatic control, Uninterrupted evaporation |

Full automatic control, Uninterrupted evaporation |

|

A.The environmental protection industry

1. High Salted Industrial Wastewater

2. environmental protection salt-containing wastewater

3. landfill leachate Chemical industry

4. pharmaceutical wastewater

5. the production of salt-containing wastewater

6. chemical products concentrated or crystallization

7. Mining Wastewater Treatment

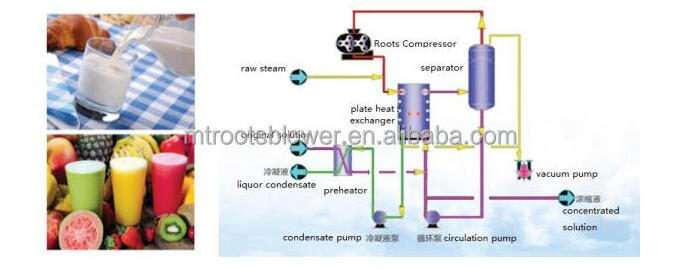

B.The food industry

Sugar, milk, Concentration, and extraction of fructose,Soft Drinks, Beverages, amino acids concentration, etc.

1.Our company run business for 15 years history since establishment

2. Our company Introduced advanced processing technology from European and Japan,including CAD,CAM,CAPP with perfect combination of our company own proven high technology and rich experience

3. Zero defective MVR Evaporator leave from the factory

4. Strict quality management system and performance testing system

5.All production follow up ISO 9001 Standard and 9S Management Standards .

8. Oil-free, no oil pollution for transportation medium

10. Compact structure with graceful appearance

11. More than 20 inventions and utility model patents

12. ISO 9001/ISO14001/OHSAS18001 and CE Certified.

1 3. Shangu Brand Registered under Madrid International Trademark .

1 4. L onger service life and lower cost for more profitable for customers

1 5 .15% More energy saving than multiple-effect evaporator.

16 . Lower rotary speed ensures extension of service life and reduces maintenance cost.

17. Process every spare part with special and dedicated care.

18 . Strong technical talents and experts as support , 3 domestic experts,15 technical engineers, and 38 technicians.

19. More than 30 sets of processing machines including imported machining centers, planers, boring machines, milling machines, two-way curve planers,etc.to ensure processing precision of each spare parts and stable operation of roots blower.

20.Export to more than 20 countries including Southeast Asia ,South Asia,Africa and Middle and South America .

21. No Complaints about quality and service for continuous 15 years.