High quality resin sand

Taiwan spindle

Automatic lubrication system

Chip conveyor at optional

System:KND-1000M

16 Armless Tool Magazine

3 axis linear rail

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

360

-

Dimension(L*W*H):

-

1900x1700x2100

-

Weight (T):

-

3 T

-

Positioning Accuracy (mm):

-

0.0075

-

Repeatability (X/Y/Z) (mm):

-

0.005

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

5.5

-

Max. Table Load(kg):

-

300 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Luzhong Machine Tool

-

Voltage:

-

380V

-

Warranty of core components:

-

13 months

-

Product name:

-

GSK SIEMENS control fresadora cnc VMC640 cnc milling machine metal

-

Table size:

-

800x300mm

-

X axis travel:

-

600mm

-

Y axis travel:

-

360mm

-

Z axis travel:

-

450mm

-

Spindle taper:

-

BT40

-

Max. spindle speed:

-

8000rpm

-

Repeat accuracy:

-

±0.0075

-

Application:

-

Metal Machining

-

Certification:

-

ISO CE

Quick Details

-

Table Size (mm):

-

800x300

-

Number of Axes:

-

3, 4

-

Table Travel (X) (mm):

-

600

-

Table Travel (Y) (mm):

-

360

-

Dimension(L*W*H):

-

1900x1700x2100

-

Weight (T):

-

3 T

-

Positioning Accuracy (mm):

-

0.0075

-

Repeatability (X/Y/Z) (mm):

-

0.005

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

5.5

-

Max. Table Load(kg):

-

300 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Luzhong Machine Tool

-

Voltage:

-

380V

-

Warranty of core components:

-

13 months

-

Product name:

-

GSK SIEMENS control fresadora cnc VMC640 cnc milling machine metal

-

Table size:

-

800x300mm

-

X axis travel:

-

600mm

-

Y axis travel:

-

360mm

-

Z axis travel:

-

450mm

-

Spindle taper:

-

BT40

-

Max. spindle speed:

-

8000rpm

-

Repeat accuracy:

-

±0.0075

-

Application:

-

Metal Machining

-

Certification:

-

ISO CE

Products Description

The main performance characteristics:

|

specifications

|

unit

|

VMC640

|

|

Table size

|

mm

|

800x300

|

|

Max. worktable load

|

kg

|

300

|

|

T slot(number-width-pitch)

|

|

3-16*80

|

|

X axis travel

|

mm

|

600

|

|

Y axis travel

|

mm

|

360

|

|

Z axis travel

|

mm

|

450

|

|

Distance from spindle axis to column surface

|

mm

|

383

|

|

Distance between spindle nose and worktable surface

|

mm

|

100-550

|

|

Max. spindle speed

|

r/min

|

8000(10000 optional)

|

|

Spindle taper

|

mm

|

BT40

|

|

Main motor power

|

kw

|

5.5

|

|

X/Y/Z rapid traverse speed

|

m/min

|

20/20/20

|

|

Cutting feed speed

|

mm/min

|

1-8000

|

|

X/Y/Z motor connection

|

|

Direct

|

|

Guide rail type

|

|

Linear rail

|

|

Positioning accuracy

|

mm

|

±0.008

|

|

Repeat positioning accuracy

|

mm

|

±0.008

|

|

Tool magazine type

|

|

Armless

|

|

Tool magazine capacity

|

pcs

|

16

|

|

Max. tool diameter

|

mm

|

90

|

|

Max.tool weight

|

kg

|

8

|

|

Machine weight

|

kg

|

2600

|

|

Overall dimension

|

mm

|

1870x1600x2000

|

VMC Machine Standard Details

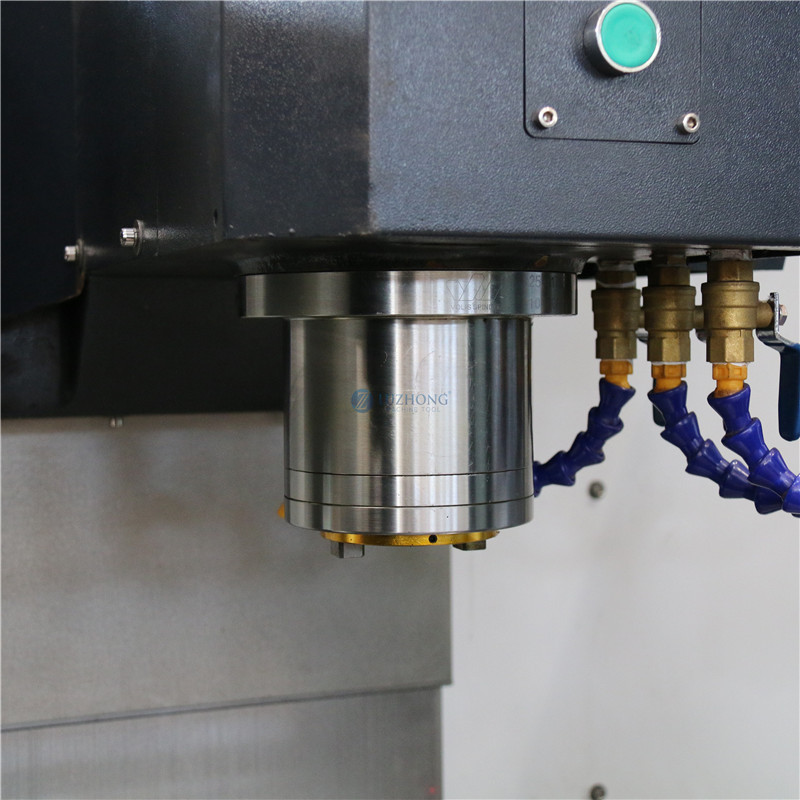

TAIWAN PRECISION SPINDLE

1. Spindle taper is BT40;

2. Spindle speed 8000rpm , can enlarge to 10000rpm or 12000rpm

3. Taiwan Spindle passed dynamic balance ISO rating test

3. Taiwan Spindle passed dynamic balance ISO rating test

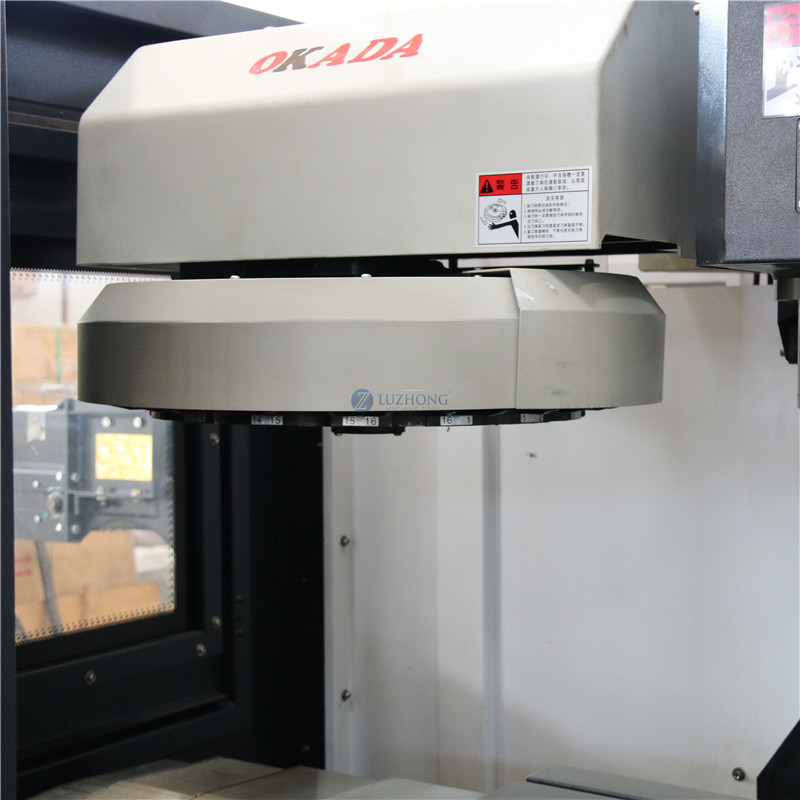

TAIWAN TOOL MAGAZINE

1. Standard with Taiwan armless tool magazine .

2. Optional: Taiwan 24 Arm tool magazine, tool change time only 3 seconds.

3. Brand: OKADA

TAIWAN PRECISION LINEAR RAILS

1. Taiwan high speed roller linear guide rail, positioning accuracy can reach μm class

2. Brand: HIWIN or PMI

2. Brand: HIWIN or PMI

SCREW AND COUPLING

1 China famous brand lead screw,

2. lead screw bearing using SKF or NACHI bearing,

3. coupling R+W directly connected

3. coupling R+W directly connected

CONTROL SYSTEM

Standard: GSK / KND control

Optional : Siemens , FANUC, Syntec ect.

AIR CONDITIONER

Standard with Industrial electrical cabinet air conditioner.

Cooling the electric box better .

TOOL UNCLAMP CYLINDER

Taiwan spindle Tool unclamp cylinder

AIR STORAGE TANK

Air storage tank to ensure the stability of spindle tool change

STRONG CHIP PUNCHING

1. High strength high quality cast iron,

2. long span bed base and vertical column structure

AIR GUN AND WATER GUN

High-pressure air guns and high-pressure water guns

MACHINE CONSTRUCT

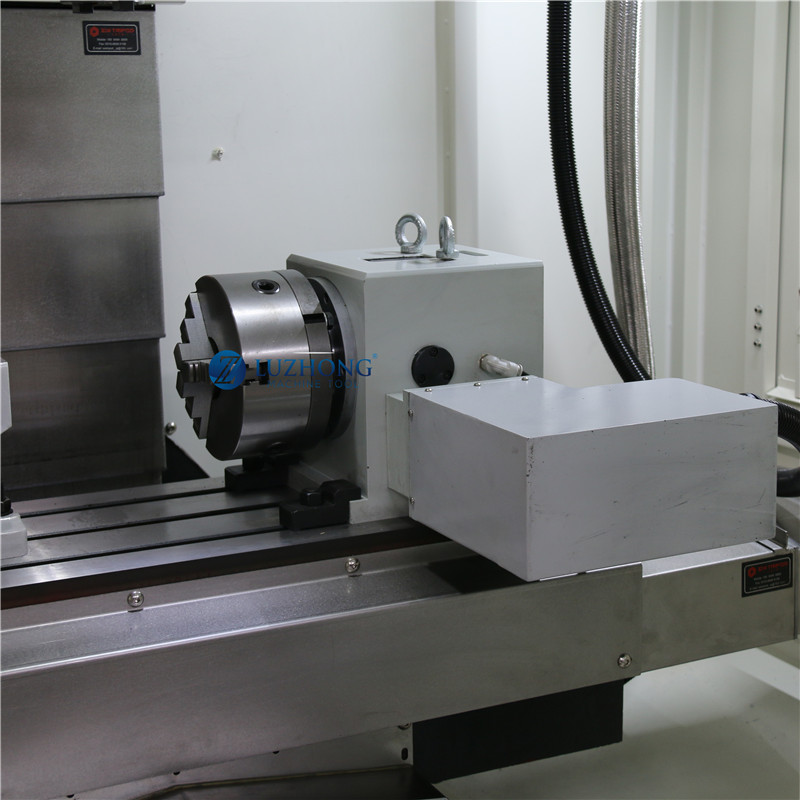

1. Standard with Milling chuck

SCHNEIDER ELECTRICAL COMPONENTS

1. with Schneider safety electrical components

2. quick plug as standard

LUBRICATION SYSTEM

Automatic centralized lubrication device .

.

TESTING

Each machine passed Renishaw laser interferometer testing and ballbar testing

Recommend Products

Hot Searches