- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RS-S

-

Standard:

-

EN 12350-5 / BS 1881:105 / DIN 1048 / UNI 8020

-

Steel Ruler Material:

-

Stainless Steel

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RUSHI

-

Model Number:

-

RS-S

-

Standard:

-

EN 12350-5 / BS 1881:105 / DIN 1048 / UNI 8020

-

Steel Ruler Material:

-

Stainless Steel

Product Description

Flow table test of concrete to test workability of concrete.Workability is a complex property of concrete which directly impacts on Concrete strength, quality and appearance and it also determines how easily freshly made concrete can be mixed, placed,compacted and finished with the minimum to no loss concerning homogeneity.

Specification

|

item

|

value

|

|

Warranty

|

1 Year

|

|

Customized support

|

OEM, ODM, OBM, Software reengineering

|

|

Place of Origin

|

China

|

|

|

Hebei

|

|

Brand Name

|

RUSHI

|

|

Model Number

|

RS-S

|

|

Standard

|

EN 12350-5 / BS 1881:105 / DIN 1048 / UNI 8020

|

|

Steel Ruler Material

|

Stainless Steel

|

Product Description

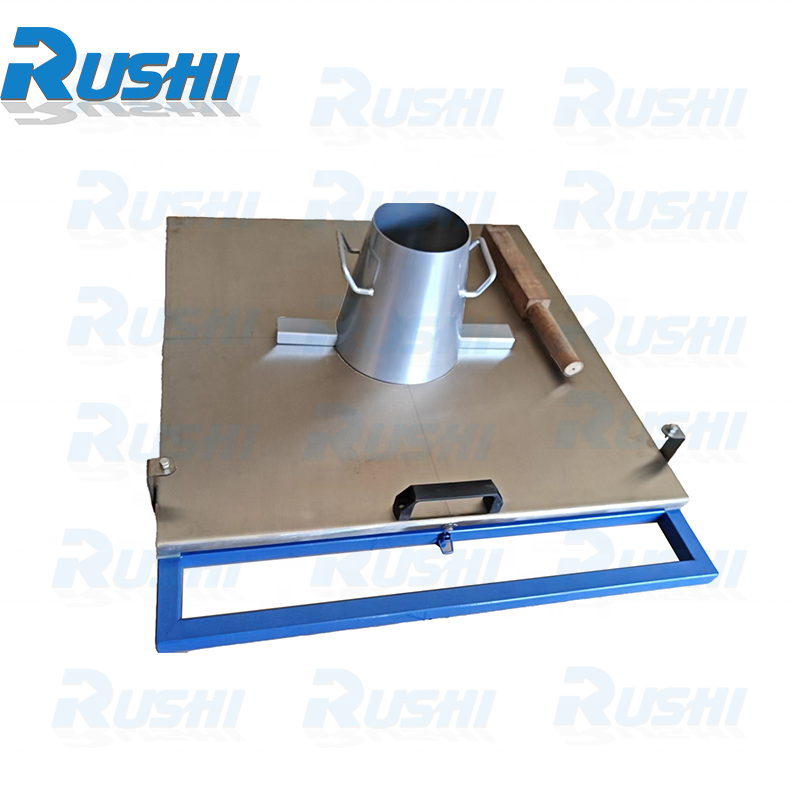

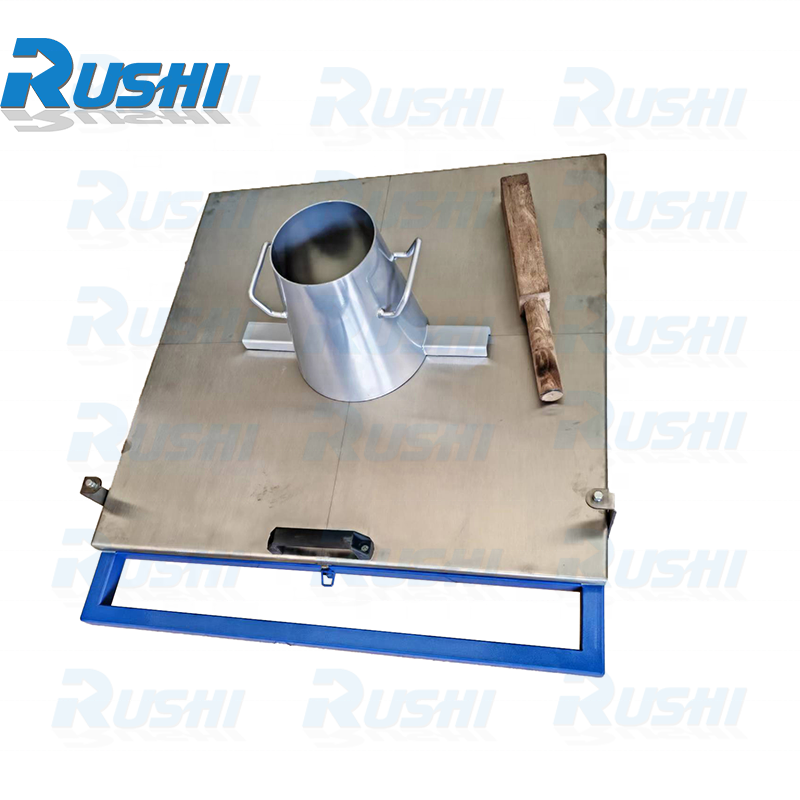

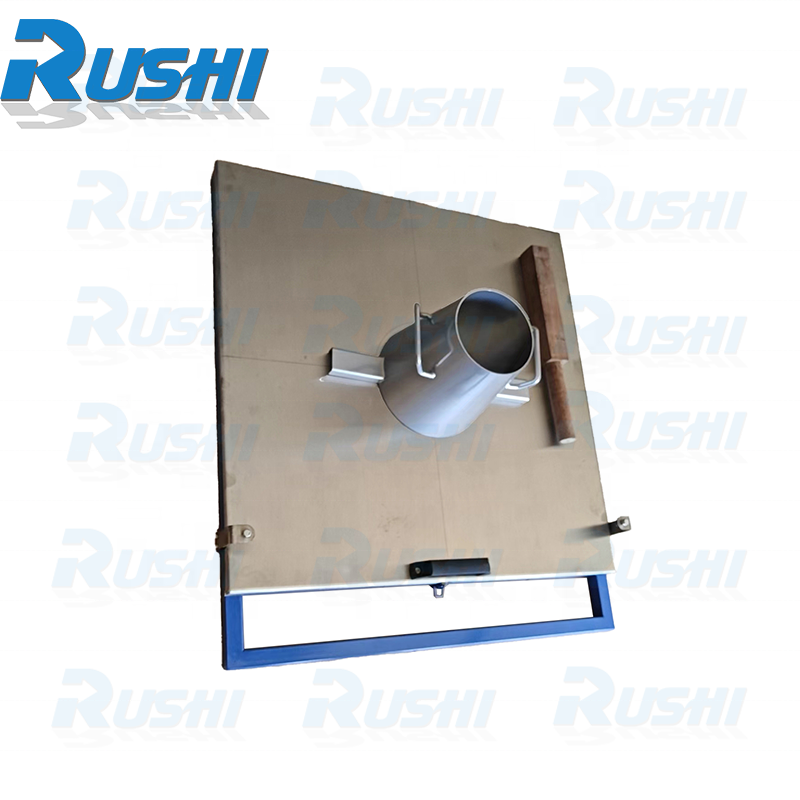

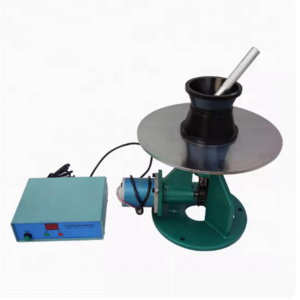

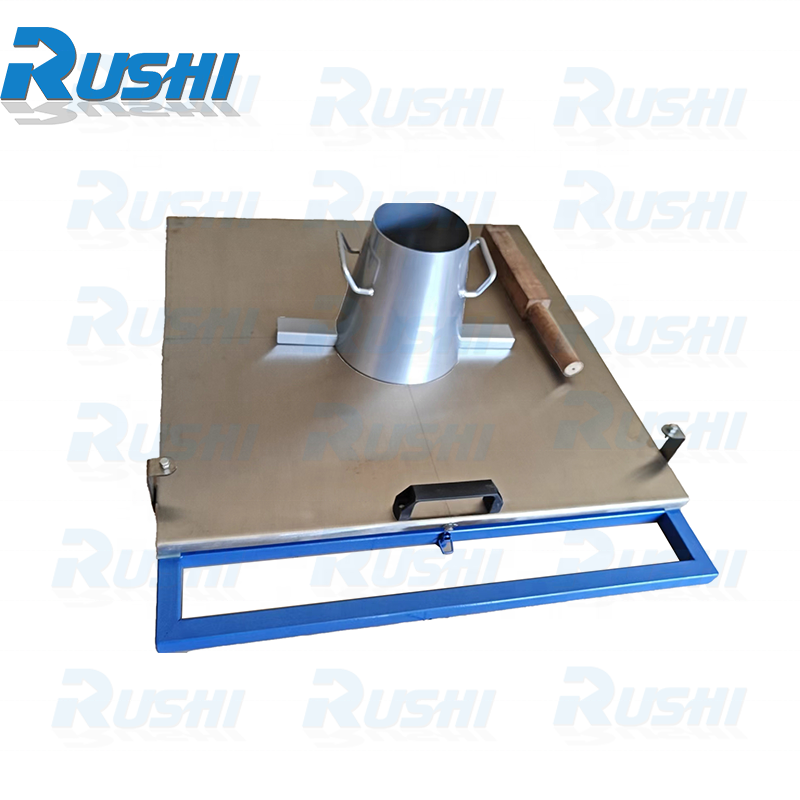

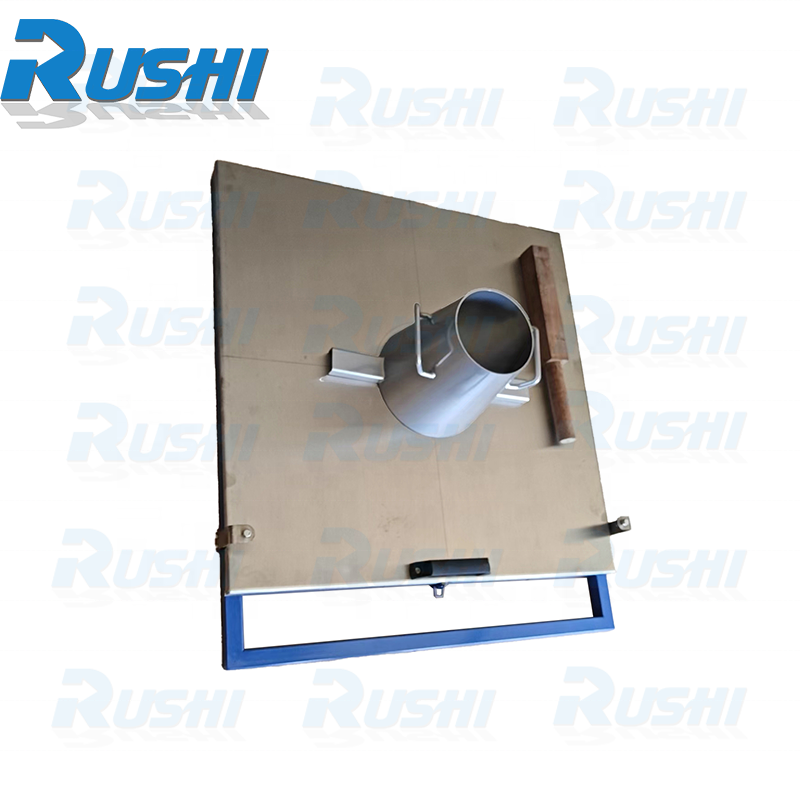

The apparatus comprises a galvanized steel conical mould, dia. 130/200 xh 200 mm, steel flow table with galvanized top plane,guide device, tamper.

Used to determine the workability of concrete. The top table has a square surface of 700x700 mm,

Weight: 30 kg

SPARES:

1.Conical mould, galvanized steel made,dia. 130/200 xh 200 mm

2. Tamper

Flow table test of concrete to test workability of concrete

Workability is a complex property of concrete which directly impacts on Concrete strength, quality and appearance and it also determines how easily freshly made concrete can be mixed, placed, compacted and finished with the minimum to no loss concerning homogeneity.

Apparatus of Flow Table Test:

Flow table made of metal having thickness 1.5mm and dimensions 700mmx 700mm, tamping rod , Scoop, Centimeter Scale, Metal Cone or mould (Lower Dia = 20cm, upper Dia = 13 cm, Height of Cone = 20cm). The middle portion of flow table is marked with a concentric circle of dia 200mm to place a metal cone on it. A lift handle

The more details about Flow table is depicted in the below image go through it if required.

Used to determine the workability of concrete. The top table has a square surface of 700x700 mm,

Weight: 30 kg

SPARES:

1.Conical mould, galvanized steel made,dia. 130/200 xh 200 mm

2. Tamper

Flow table test of concrete to test workability of concrete

Workability is a complex property of concrete which directly impacts on Concrete strength, quality and appearance and it also determines how easily freshly made concrete can be mixed, placed, compacted and finished with the minimum to no loss concerning homogeneity.

Apparatus of Flow Table Test:

Flow table made of metal having thickness 1.5mm and dimensions 700mmx 700mm, tamping rod , Scoop, Centimeter Scale, Metal Cone or mould (Lower Dia = 20cm, upper Dia = 13 cm, Height of Cone = 20cm). The middle portion of flow table is marked with a concentric circle of dia 200mm to place a metal cone on it. A lift handle

The more details about Flow table is depicted in the below image go through it if required.

Procedure of flow table test:

Prepare concrete as per mix design and place the flow table on a horizontal surface.

Clean the dust or other gritty material on Flow table and Sprinkle a hand of water on it.

Now place the metal cone at the middle portion of the flow table and stand on it.

Pour the freshly mixed concrete in the mould comprising two layers; each layer should be tamped with tamping rod for 25times.

After tamping the last layer, the overflowed concrete on the cone is struck off using a trowel.

Slowly, lift the mould vertically up & let concrete stand on its own without any support.

The flow table is raised at the height of 12.5mm and dropped. The same is repeated for 15times in 15secs.

Measure the spread of concrete in Diameter using centimetre scale horizontally and vertically. The arithmetic mean of the two diameters shall be the measurement of flow in millimetres.

Clean the dust or other gritty material on Flow table and Sprinkle a hand of water on it.

Now place the metal cone at the middle portion of the flow table and stand on it.

Pour the freshly mixed concrete in the mould comprising two layers; each layer should be tamped with tamping rod for 25times.

After tamping the last layer, the overflowed concrete on the cone is struck off using a trowel.

Slowly, lift the mould vertically up & let concrete stand on its own without any support.

The flow table is raised at the height of 12.5mm and dropped. The same is repeated for 15times in 15secs.

Measure the spread of concrete in Diameter using centimetre scale horizontally and vertically. The arithmetic mean of the two diameters shall be the measurement of flow in millimetres.

Packing & Delivery

Concrete Flow Table

is wooden case.

Supply Ability

1000 Set/Sets per Month.

Hot Searches