- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KAIQIAN

-

Voltage:

-

Custom

-

Power:

-

Custom

-

Dimension(L*W*H):

-

Custom

-

Weight:

-

kg

-

Product name:

-

Waste Oil Distillation Plant

-

Function:

-

Remove water, gas, impurities,acetylene

-

Application:

-

waste engine oil, pyrolysis oil,lubricate oil

-

Raw material:

-

Carbon steel

-

Name:

-

Waste oil distillation machine

-

Color:

-

blue, grey, green, yellow

-

Heating method:

-

eletric heater

-

Filtration classification:

-

Three Stages Filtration

-

Advantages:

-

self defoaming

-

Suitable Oil:

-

transformer oil, insulation oil

Quick Details

-

Marketing Type:

-

Custom products

-

Flow:

-

20-200 L/min

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

KAIQIAN

-

Voltage:

-

Custom

-

Power:

-

Custom

-

Dimension(L*W*H):

-

Custom

-

Weight:

-

kg

-

Product name:

-

Waste Oil Distillation Plant

-

Function:

-

Remove water, gas, impurities,acetylene

-

Application:

-

waste engine oil, pyrolysis oil,lubricate oil

-

Raw material:

-

Carbon steel

-

Name:

-

Waste oil distillation machine

-

Color:

-

blue, grey, green, yellow

-

Heating method:

-

eletric heater

-

Filtration classification:

-

Three Stages Filtration

-

Advantages:

-

self defoaming

-

Suitable Oil:

-

transformer oil, insulation oil

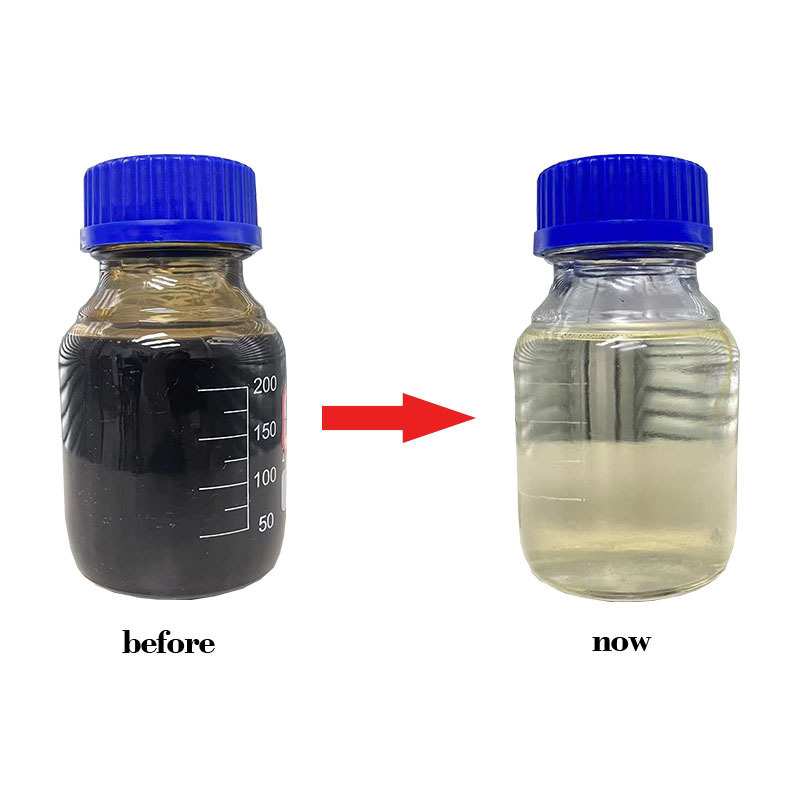

Small waste oil recovery equipment

can treat the waste engine oil, lubricant oil, all industry oil, as well as thetyre oil, plastic oil and shale oil, catalyzed pyrolysis into base oil and diesel fuel by low temperature distillation. Low cost,recovery rate higher than 85-90%, no environment pollution and energy saving.

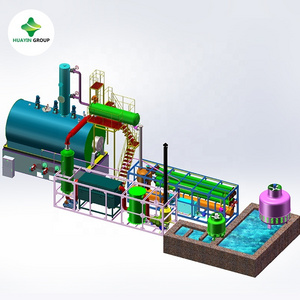

1.1 The use of thin film evaporator can quickly and effectively separate moisture and light components.

2.2. Add adsorbent in the desulfurization tower to reduce the sulfur content of the oil.

2.3. The adsorption and refining of white clay and decolorization sand are added, which can improve the quality and color of oil products and prevent the oxidation of refined oil.

2.4. Electromagnetic heating and steam generators are used to replace traditional electric heating tubes.

2.5. The equipment is equipped with platforms and stairs, which is convenient for maintenance and more beautiful.

2.6. The water curtain dust removal system purifies part of the exhaust gas.

|

No

|

Item

|

Data

|

|

1

|

Capacity

|

1~50 Tons

|

|

2

|

Working Pressure

|

≤0.5 MPa

|

|

3

|

Working Vacuum

|

-5~-20 Pa

|

|

4

|

Working temperature

|

≤350 ℃

|

|

5

|

Power Consumption

|

15KW/H~180KW/H

|

|

6

|

total Power

|

50 KW~350 KW

|

|

7

|

Cooling water

|

20~160 ³

|

|

8

|

Noted

|

We can customized the machine according to your requirements.

|

Q1: What is the application of this waste oil distillation plant?

Q2: What is the capacity of this plant?

A2: The capacity is about 1-100tons per day.

Q3: Is there any additive used inside?

A3: Yes, there will have additive use inside on the refining process, which is to further restoring the output oil

Q4: What is the heating method of this plant?

A4: Heating method is customized by customer, we support electric heating, fuel oil heating and gas heating.

A1: It is used for used engine oil, used motor oil, tyre oil,plastic oil, pyrolysis oil and other industrial oils.

Q2: What is the capacity of this plant?

A2: The capacity is about 1-100tons per day.

Q3: Is there any additive used inside?

A3: Yes, there will have additive use inside on the refining process, which is to further restoring the output oil

Q4: What is the heating method of this plant?

A4: Heating method is customized by customer, we support electric heating, fuel oil heating and gas heating.

Hot Searches