1.Are you a trading company and manufacturer?

Yes, we have have plant and trading company, we can deal business both, but do it as condition.

2.How can I get your prices?

Pls show us your target tube size (OD ,wall), material (steel grade),coating types( coating types on OD/ID both), in coil or straight length tube(if length, how long per pcs?), quantity, packing requirement ,application and special requirement. Then,we can send you an exact quotation within 24 hours.

3.What's your MOQ?

For common coating type and common size, MOQ is 2000 M ; for specially coating type or special size need confirmed.

4.How can I get some samples to do quality approved?

After quotation confirmed, we can send some samples for testing, sample tube is free, but big quantity maybe charged and freight should be bear by client.

5.What about the leading time for mass order producing?

Usually, 15-25 days for material preparing and producing after order confirmed, and 10 days for shipment booking and confirmed.35 days min for common size and type, special size and type need confirm.

6.Could the tube be customized for us?

Sure, we are professional supplier.when we confirmed and accept all your target requirement,we can customize the tube as your target.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KCGY

-

Model Number:

-

304 316

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KCGY

-

Model Number:

-

304 316

Product Description

Stainless steel long radius elbow means the bending radius is 1.5 times of outside diameter, whatever it is 90 or 45 degree elbow. Long elbow radius offers a better corrosion resistance and strength. It is long service life makes it cos-effective. It suits in many industries applications.

|

Name

|

stainless steel elbow

|

|

|

|

Production method

|

Push, pressing, forging, casting, etc

|

|

|

|

Standards

|

ASME/ ANSI B16.9, ANSI B16.28, MSS-SP-43

|

|

|

|

Size Range

|

Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″)

|

|

|

|

Path range

|

10"~84"(DN250-DN2100)

|

|

|

|

Radius of curvature R production range

|

1.5~30mm

|

|

|

|

Thickness range

|

1.5~26mm

|

|

|

|

Elbow Angle range

|

15°~180°

|

|

|

|

Form

|

Elbow, 45/90 Deg Elbow, Long Radius Elbow, Short Radius 45/90 Elbow, LR Elbow, SR Elbow, etc.

|

|

|

|

Bending Radius

|

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

|

|

|

|

Material

|

1. Stainless Steel

|

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

|

|

|

|

2.Carbon Steel

|

Q235 20# 20G 45# 15CrMo ASTM/ASME A234 WPB, WPC

|

|

|

|

3.Alloy steel

|

ASTM/ASME A234 WP 1WP 12-WP 11-WP 22-WP 5-WP 91-WP911,15Mo3 15CrMoV, 35CrMoV

|

|

|

|

4.Nickel Alloy Elbows

|

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825

INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

|

|

|

5. Non-ferrous metals

|

* Copper - for plumbing and Architectural applications

* Aluminum - light weight option but lower pressure ratings |

|

|

Value Added

Service

|

Polish (Electro & Commercial)

Heat Treatment Annealed & Pickled Sand Blasting Machining Etc. |

|

|

|

Manufacture Standard

|

ASME B16.9 Elbow, ASME B16.11, ASME B16.28, MSS SP-43, JISB2311, JIS B2312, JIS B2313, DIN 2605, DIN 2606, DIN2615, DIN2616,

BG12459-90, GB/T13401, HGJ514, SH3408, SH3409, HG/T21635, HG/T21631, Elbow DIN 2605 |

|

|

This 90° weld elbow is available in 304 or 316L stainless steel. This precision crafted sanitary butt-weld 90° elbow features a standard machine unpolished finish. This unpolished elbow is used to change flow direction in many applications across many industries when a sanitary finish is not required.

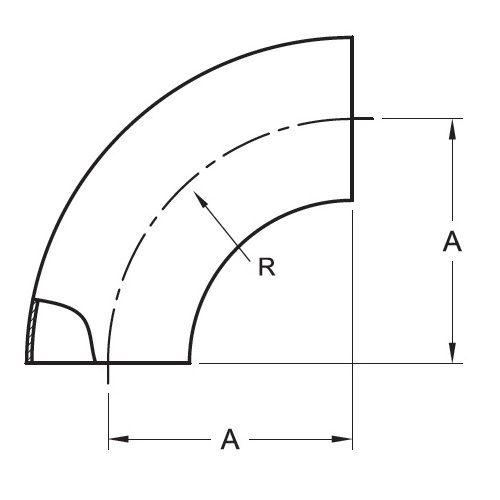

* In a long radius (LR) elbow the radius of curvature is 1.5 times the nominal diameter. In a short radious (SR) elbow the radius of curvature is 1.0 times the nominal diameter of the pipe. LR elbows give less frictional resistance to the fluid compared to the SR

* The LR elbow creates less less pressure drop i.e less friction on the other hand The SR elbow creates more pressure drop i.e more friction.

* The cost of SR elbow is more than LR elbow.

* The LR elbow creates less less pressure drop i.e less friction on the other hand The SR elbow creates more pressure drop i.e more friction.

* The cost of SR elbow is more than LR elbow.

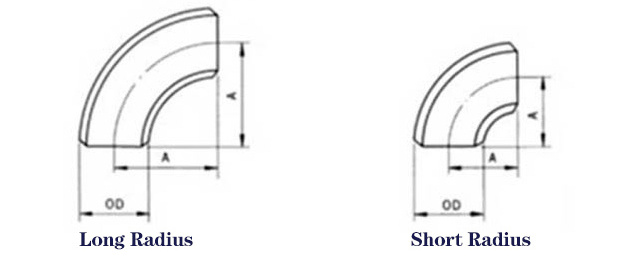

Difference in Design:

* Short Radius Elbow (SR Elbow): Has a centerline bend radius equal to the nominal pipe diameter. Has a tighter bend.

* Long Radius Elbow (LR Elbow): Features a bend radius at least 1.5x the nominal pipe diameter. More gradual, longer bending arc

* Short Radius Elbow (SR Elbow): Has a centerline bend radius equal to the nominal pipe diameter. Has a tighter bend.

* Long Radius Elbow (LR Elbow): Features a bend radius at least 1.5x the nominal pipe diameter. More gradual, longer bending arc

Key Contrasts:

* Pressure drop - Lower in long radius for a given flow rate. Less turbulent flow avoids excessive fluid momentum changes.

* Material stress - Higher in short radius fittings with tighter bending. Potential for cracking over time.

* Pipe alignment - Long radius makes alignment with adjoining straight pipe portions easier and minimizes system stress.

* Pressure drop - Lower in long radius for a given flow rate. Less turbulent flow avoids excessive fluid momentum changes.

* Material stress - Higher in short radius fittings with tighter bending. Potential for cracking over time.

* Pipe alignment - Long radius makes alignment with adjoining straight pipe portions easier and minimizes system stress.

Typical Applications:

* Long radius elbows commonly preferred for critical gas/steam/water flow for power plants, chemical/oil lines

* Short radius often used for non-binding, lower temperature/pressure lines where space is limited.

* Long radius elbows commonly preferred for critical gas/steam/water flow for power plants, chemical/oil lines

* Short radius often used for non-binding, lower temperature/pressure lines where space is limited.

|

NPS

|

O.D.

D

|

90°Long Rad

Center to End

A

|

45°Long Rad

Center to End

B

|

90°3D

Center to End

A

|

45°3D

Center to End

B

|

|

1/2

|

21.3

|

38

|

16

|

|

|

|

3/4

|

26.7

|

38

|

19

|

57

|

24

|

|

1

|

33.4

|

38

|

22

|

76

|

31

|

|

1.1/4

|

42.2

|

48

|

25

|

95

|

39

|

|

1.1/2

|

48.3

|

57

|

29

|

114

|

47

|

|

2

|

60.3

|

76

|

35

|

152

|

63

|

|

2.1/2

|

73

|

95

|

44

|

190

|

79

|

|

3

|

88.9

|

114

|

51

|

229

|

95

|

|

3.1/2

|

101.6

|

133

|

57

|

267

|

111

|

|

4

|

114.3

|

152

|

64

|

305

|

127

|

|

5

|

141.3

|

190

|

79

|

381

|

157

|

|

6

|

168.3

|

229

|

95

|

457

|

189

|

|

8

|

219.1

|

305

|

127

|

610

|

252

|

|

10

|

273

|

381

|

159

|

762

|

316

|

|

12

|

323.8

|

457

|

190

|

914

|

378

|

|

14

|

355.6

|

533

|

222

|

1067

|

441

|

|

16

|

406.4

|

610

|

254

|

1219

|

505

|

|

18

|

457

|

686

|

286

|

1372

|

568

|

|

20

|

508

|

762

|

318

|

1524

|

632

|

|

22

|

559

|

838

|

343

|

1676

|

694

|

|

24

|

610

|

914

|

381

|

1829

|

757

|

|

26

|

660

|

991

|

406

|

1981

|

821

|

|

28

|

711

|

1067

|

438

|

2134

|

883

|

|

30

|

762

|

1143

|

470

|

2286

|

946

|

|

32

|

813

|

1219

|

502

|

2438

|

1010

|

|

34

|

864

|

1295

|

533

|

2591

|

1073

|

|

36

|

914

|

1372

|

565

|

2743

|

1135

|

|

38

|

965

|

1448

|

600

|

2896

|

1200

|

|

40

|

1016

|

1524

|

632

|

3048

|

1264

|

|

42

|

1067

|

1600

|

660

|

3200

|

1326

|

|

44

|

1118

|

1676

|

695

|

3353

|

1389

|

|

46

|

1168

|

1753

|

727

|

3505

|

1453

|

|

48

|

1219

|

1829

|

759

|

3658

|

1516

|

Chemical composition

|

Chemical Composition

|

|

|

|

|

|

|

|

|

||||||||

|

304

|

SUS304

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

||||||||

|

304

|

SUS304

|

≤0.07

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

8.0-10.5

|

17.5-19.5

|

||||||||

|

304H

|

|

0.04-0.10

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

8.0-10.5

|

18.0-20.0

|

||||||||

|

304L

|

SUS304L

|

≤0.030

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

8.0-12.0

|

17.5-19.5

|

||||||||

|

304N

|

SUS304N1

|

≤0.08

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

8.0-10.5

|

18.0-20.0

|

||||||||

|

309S

|

SUS309S

|

≤0.08

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

12.0-15.0

|

22.0-24.0

|

||||||||

|

310S

|

SUS310S

|

≤0.08

|

≤1.50

|

≤2.00

|

≤0.045

|

≤0.030

|

19.0-22.0

|

24.0-26.0

|

||||||||

|

316

|

SUS316

|

≤0.08

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

10.0-14.0

|

16.0-18.0

|

||||||||

|

316L

|

SUS316L

|

≤0.030

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

10.0-14.0

|

16.0-18.0

|

||||||||

|

317L

|

SUS317L

|

≤0.030

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

11.0-15.0

|

18.0-20.0

|

||||||||

|

321

|

SUS321

|

≤0.08

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

9.0-12.0

|

17.0-19.0

|

||||||||

|

347

|

SUS347

|

≤0.08

|

≤0.75

|

≤2.00

|

≤0.045

|

≤0.030

|

9.0-13.0

|

17.0-19.0

|

||||||||

|

904L

|

SUS890L

|

≤0.020

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.035

|

23.0-28.0

|

19.0-23.0

|

||||||||

More Products

Packing & Delivery

Elbows need to be packed in wooden cases when they are shipped.The total amount of small elbows does not exceed 1 ton,Large size elbows need to be packed separately.

In addition, the wooden box packing clearly indicates the elbow size, steel number, batch number, manufacturer's trademark, etc.

Production Line

FAQ

Hot Searches