- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Oler

-

Model Number:

-

OL-147

-

MOQ:

-

200PCS

-

Sample time:

-

7-10 Days

-

Description:

-

Iron

-

Function:

-

Storage basket

-

Payment:

-

Negotiable

-

PAYMENT TERM:

-

As request

-

Service:

-

Quick Response Service

-

Size:

-

25*12*15.5mm

-

N.W:

-

0.208

-

Packing:

-

24pcs/ctn

Quick Details

-

Functional design:

-

Multifunction

-

Dimensional tolerance:

-

<±3mm

-

Weight tolerance:

-

<±3%(Include)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Oler

-

Model Number:

-

OL-147

-

MOQ:

-

200PCS

-

Sample time:

-

7-10 Days

-

Description:

-

Iron

-

Function:

-

Storage basket

-

Payment:

-

Negotiable

-

PAYMENT TERM:

-

As request

-

Service:

-

Quick Response Service

-

Size:

-

25*12*15.5mm

-

N.W:

-

0.208

-

Packing:

-

24pcs/ctn

Product Description

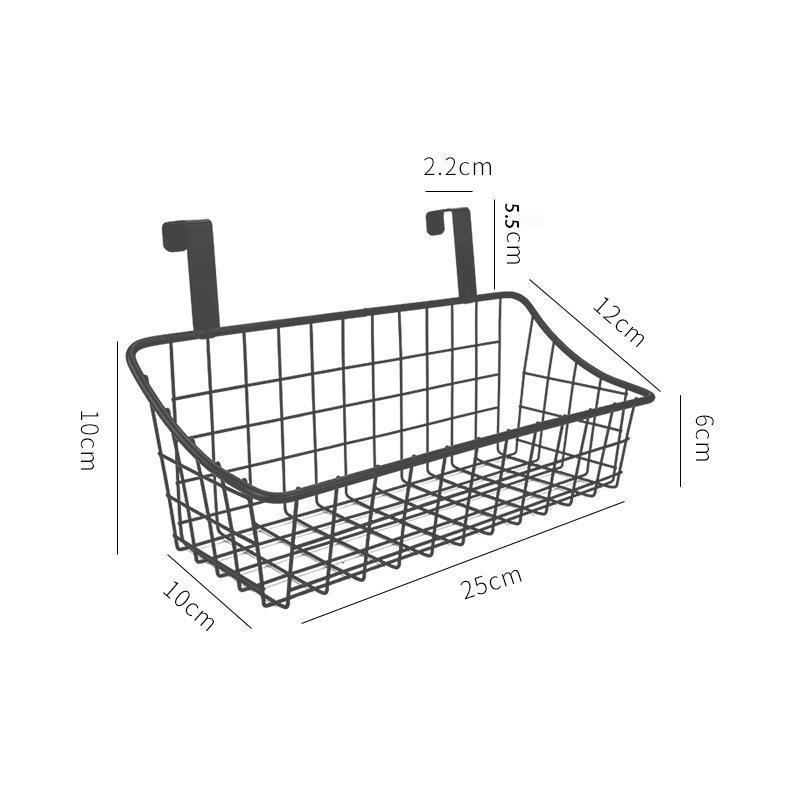

Specification

|

Product Name

|

Iron Storage Metal Wire Baskets

|

|

Item No.

|

OSB-208

|

|

Meterial

|

iron

|

|

Material Details

|

Round wire: Ø4.5/1.5; Plate:1.5

|

|

Surface Treatment

|

Black powder coated/Chrome finished/Nickel coated

|

|

Product Size

|

25*12*15.5mm

|

|

N.W./PC

|

0.208KG

|

|

Package |

12pcs/Ctn

|

Other Styles

Manufacturing Technique

Step 1: 3D Drawing

Before confirming the order, we can draw 3D drawings according to the customer's requirements.

Step 2: Molding

Different products have different molds.We will make suitable mold for mass production.

Step 3: Cutting

We will cut the raw material into the suitable size before put it in the fixture(mold) to weld.

Step 4: Auto-Bending

Our automatic bending machine can make metal wire into different shapes and sizes before put it in the fixture(mold) to weld.

Step 5: Punching

The punching process makes welding easier and can be made into different shapes.

Step 6: Spot Welding

We will put different size material into the mold,and they are held together under pressure exerted by electrodes.

Step 7: Welding

We will use welding machine,all work-pieces are held together under the pressure exerted by the electrodes.

Step 8: Automatic Welding

We will use automatic welding machine,all work-pieces are held together under the pressure exerted by the electrodes.

Step 9: Trimming

For the surplus part, we will trim it before grinding.

Step 10: Grinding

All products will be grinding to make the surface and without sharp corner scraper place.

Step 11: QC

Our QC colleagues should check every product before

products leveling control process

.

Step 12: Products Leveling Control

For provide excellent product to customer ,we have control the leveling of the product before surface treatment.

Step 13: Assembling

We will assemble some accessories, such as rubber particles and card.

Step 14: Packing

After QC inspection&assembling, we will pack according to the customer's requirements.

Step 15: Finished Products

After packaging, it will be temporarily stored in the warehouse and arranged for delivery.

Packing & Delivery

Hot Searches