- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Safed

-

Product name:

-

wheat corn paddy rice grain dryer

-

Materials:

-

SUS304, SUS316, Carbon Steel or customized

-

Heating source:

-

Natural Gas.biomass Pellet,etc

-

Move type:

-

With Wheel

-

Raw material:

-

Grains soybean Wheat Rice Corn,etc

-

Where to Use:

-

Both outdoor and indoor available

-

Voltage:

-

380v or customized voltage

-

Function:

-

Grains soybean Wheat Rice Corn drying

Quick Details

-

Weight (KG):

-

1600

-

Type:

-

Grain dryer equipment

-

Use:

-

Grains drying

-

Place of Origin:

-

China

-

Brand Name:

-

Safed

-

Product name:

-

wheat corn paddy rice grain dryer

-

Materials:

-

SUS304, SUS316, Carbon Steel or customized

-

Heating source:

-

Natural Gas.biomass Pellet,etc

-

Move type:

-

With Wheel

-

Raw material:

-

Grains soybean Wheat Rice Corn,etc

-

Where to Use:

-

Both outdoor and indoor available

-

Voltage:

-

380v or customized voltage

-

Function:

-

Grains soybean Wheat Rice Corn drying

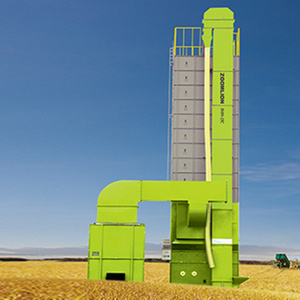

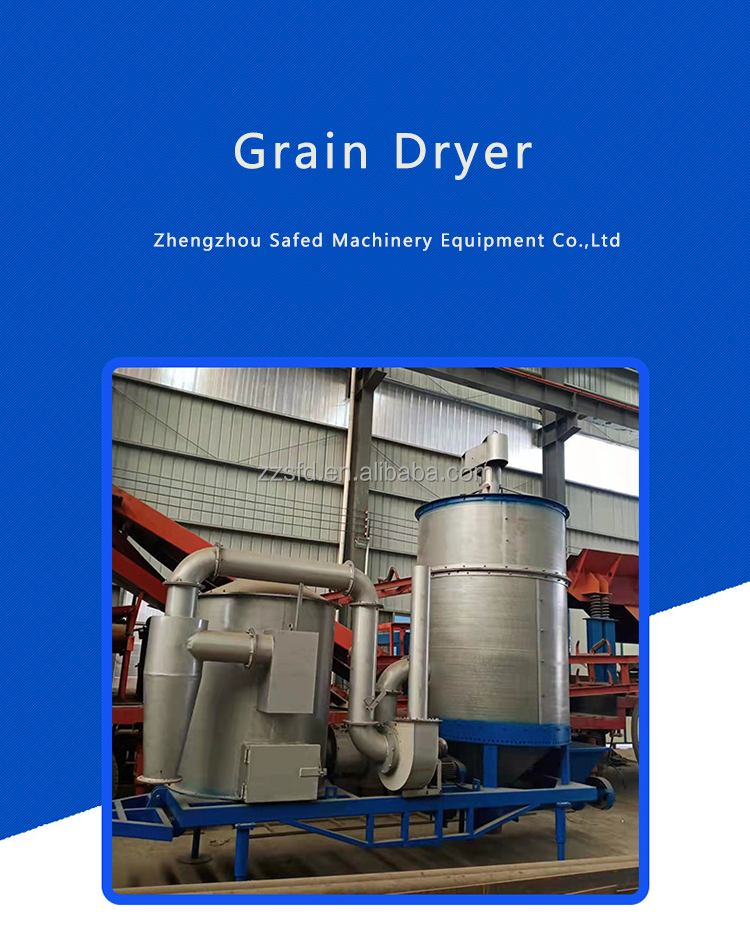

Hot air small paddy spent grain drying machine wheat corn paddy rice grain dryer

1. Introduction of

Mobile grain dryer

:

The small walking grain drying equipment is a batch type internal recycle-based grain drying equipment as developed by the researchers of the Design Institute for Complete Equipment under the China Agricultural University (formerly known as Beijing University of Agricultural Engineering) by referring to the advanced technologies of foreign countries and on the basis of China’s national situation. This device is applicable to the drying of corn, wheat, rice and other grain crops, especially the drying of rice, and is characterized by such advantages as low cracking rate, fewer broken rice, high whiteness and high quality.

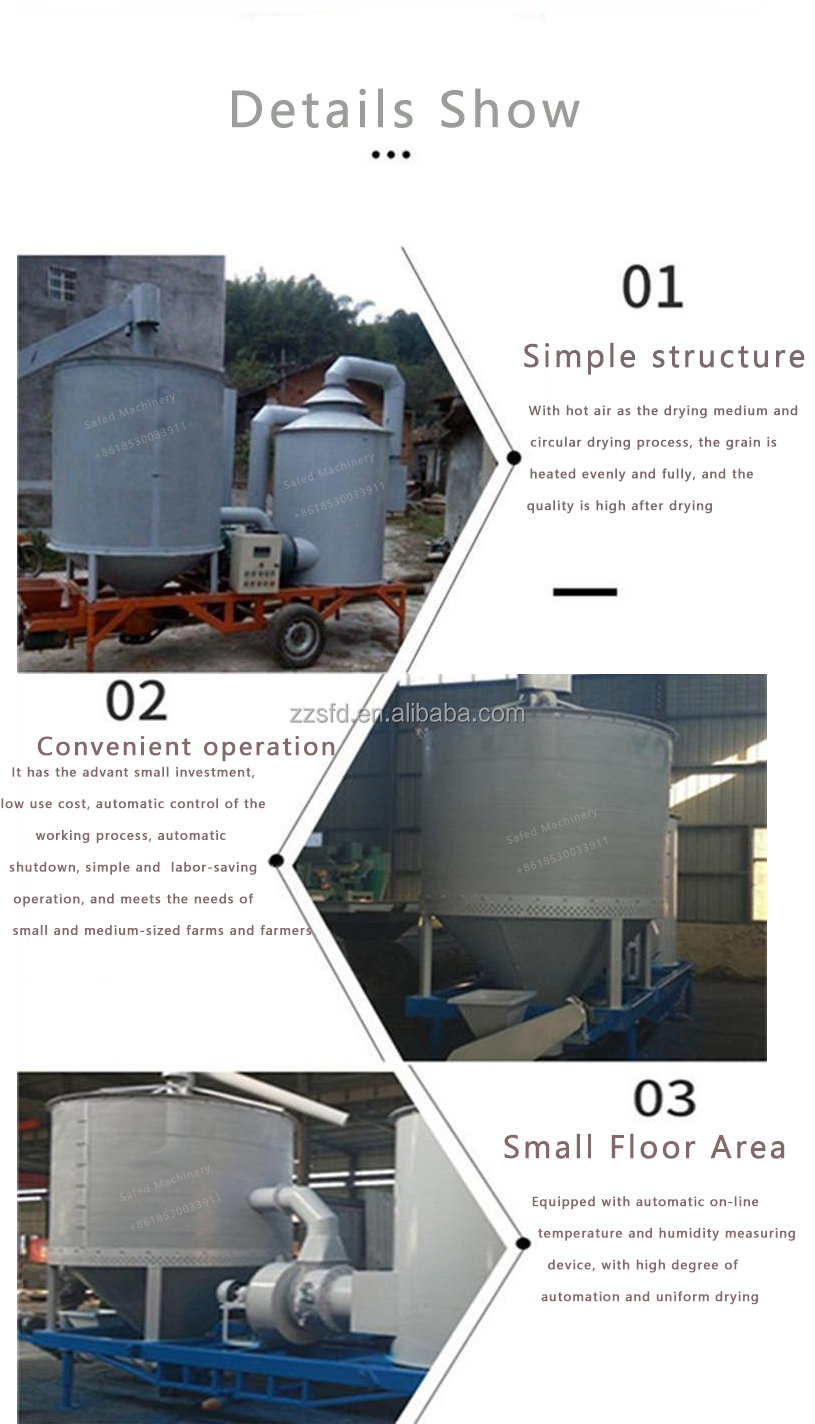

2.Advantages of mobile grain dryer machine :

• Outdoor dryer can reduce building cost

The outdoor dryer needn’t build a drying room, small area occupation, shorten the installation period, reduce the cost of the whole equipment; they are very helpful to achieve profitable operations.

• High moisture paddy or wheat can be dried easily

The internal distribution of “v” shape “hill-shaped multi-tube structure” can circulate mixing grain perfectly, prevent drying inhomogeneous, crackle, over drying etc, high moisture paddy or wheat can be dried easily and the quality can be guaranteed after drying by low temperatures, high winds, comprehensive ventilation structure.

• Installation working hours can be reduced by semi-products delivery

Many parts have been assembled before delivery, it can reduce installation working hours, reduce the time limit from project and costs on site. In addition, wires and pipe work, wiring material, and the air pipe etc are also carried out simultaneously, when the completion installation of the mechanical parts, they can also be finished together at the same time.

Advanced technology in drying industry

The dryer is designed with mixed flow drying principle, resulting in high heating efficiency, low energy consumption and large capacity. By mixed flow and low temperature drying, moisture is reduced slowly and evenly, thus damaging by heating is minimized. The grain is kept in good quality after drying with least cracking.

•

The machine adopts patented discharge technology, so that

discharging is more stable, uniform, without cleaning.

•

Mind brand tower type grain dryer utilize advanced distinctive dust removing technology, which

improves working environment

3.Operating princip l es of mobile grain dryer:

Mobile dryer is also called the grain dryers, grain drying machine is an ideal equipment for drying grain and oil, processed products from the top input, through the feeding device, to ensure that the equipment always in full load condition during operation. After turning inward bottomless v-shaped flap and processing with staggered joint action of multiple rows of "V" baffle, makes possible the mix of processed products, but also as dry air in and out of the channel, the fan will be used gas into the collector, purification, most of the dry air can be recycled, so save the fuel consumption.

Specification:

|

Model |

SFD- 2D |

SFD- 4D |

SFD- 6D |

SFD- 10D |

|

|

Silo Volume |

3.8m³ |

6.5m³ |

9.6m³ |

15.6m³ |

|

|

Dry type |

Low temperature hot air and grain Mixed flow cycle |

||||

|

Hot air temperature |

Paddy:45-60℃;Corn:100-130℃;Wheat:90-110℃ |

||||

|

Transport height |

2.7m |

2.9m |

2.9m |

2.95m |

|

|

Operation height |

3.46m |

3.85m |

4.92m |

6.65m |

|

|

Area |

13m2 |

15.5m2 |

16.3m2 |

25m2 |

|

|

Oven |

Clean oven |

||||

|

Ignition by manual |

|||||

|

Fuel can be coal,desiel oil,natural gas,etc |

|||||

|

Fuel consumption |

Coal |

(Standard conditions)18kg/t |

|||

|

Gas |

(Standard conditions)7m³/t |

||||

|

Diesel oil |

(Standard conditions)7.5L/t |

||||

|

Total power |

8.5 |

12.9 |

19.4 |

36 |

|

|

Daily Production: |

20 t/day |

35 t/day |

50 t/day |

80-100 t/day |

|

|

Room temperature |

-10-40℃ |

||||

|

Feeding time |

8-10 min |

12-16 min |

18-22 min |

22-28 min |

|

|

Discharging time |

8-10 min |

10-15 min |

15-20 min |

20-25 min |

|

|

Precipitation rate (%/h) |

Paddy:1.7-2.5℃;Corn:3.8-6;Wheat:2.8-4.5℃ |

||||

|

Safety Devices |

Thermal relay,Error alarm, Times Switch, Overheat alam |

||||

|

The performance of above parameter and Precipitation rate is for reference value,the actual value will be different due to atmospheric temperature,relative humidity,dry species,hot air temperature and moisture content and drying rate.Daily production is calculated by the condition from25% to 14% moisture. |

|||||

User Site:

Packing:Standard export packing or as buyer's request

Shipping:in 7-30 days after receiving the order

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life