- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LYM-Liye Machinery

-

Power (kW):

-

11

-

Weight (KG):

-

5500

-

Machine Type:

-

Pipe and Tube Bending Machine

-

Raw Material:

-

PIPE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

DW89CNCx2A-2S CNC 3D pipe bending machine / price of cnc machinery ben

-

Measurement size of machine:

-

5650*1350*1360mm

-

Certificates:

-

CE&ISO&BV

-

Feeding method:

-

Direct feeding/Clamping feeding

-

Bending method:

-

hydraulic bending

-

Max hydraulic pressure:

-

14MPa

-

OEM&ODM:

-

available

Quick Details

-

Bending Radius (mm):

-

1.5 - 250

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

±0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LYM-Liye Machinery

-

Power (kW):

-

11

-

Weight (KG):

-

5500

-

Machine Type:

-

Pipe and Tube Bending Machine

-

Raw Material:

-

PIPE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

DW89CNCx2A-2S CNC 3D pipe bending machine / price of cnc machinery ben

-

Measurement size of machine:

-

5650*1350*1360mm

-

Certificates:

-

CE&ISO&BV

-

Feeding method:

-

Direct feeding/Clamping feeding

-

Bending method:

-

hydraulic bending

-

Max hydraulic pressure:

-

14MPa

-

OEM&ODM:

-

available

cnc machinery bender

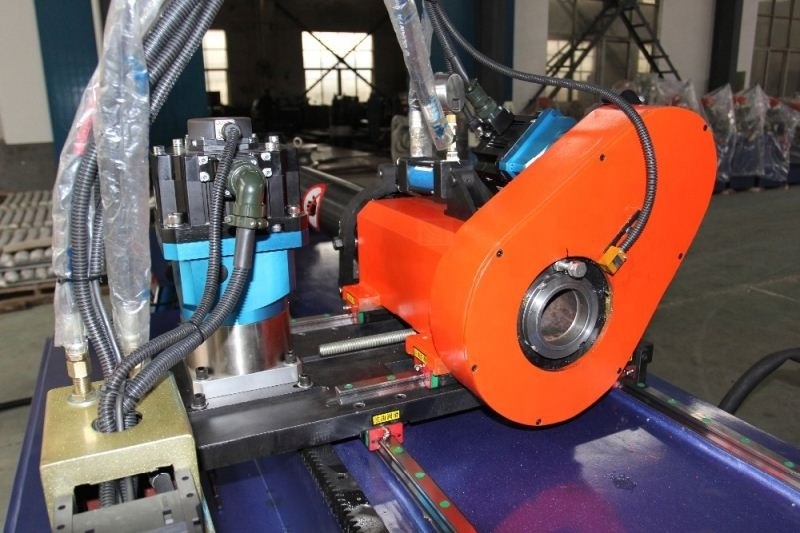

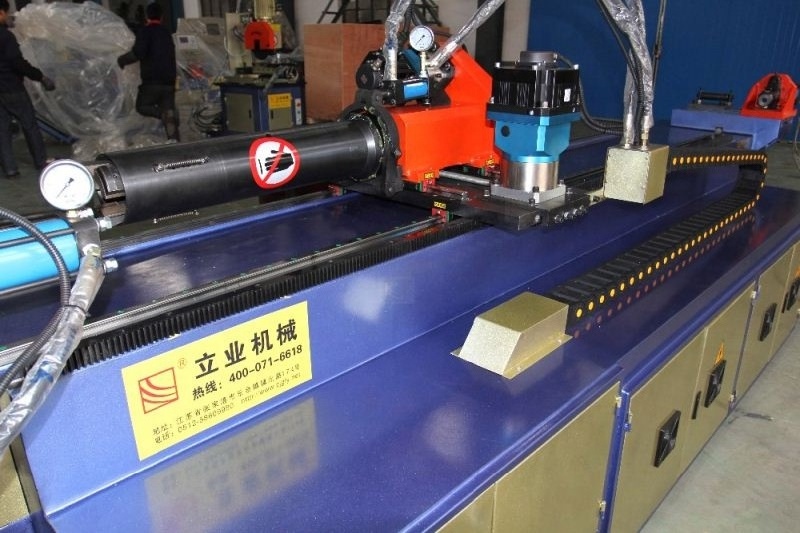

DW89CNCx2A-2S CNC 3D pipe bending machine / price of cnc machinery bender

Specification:

| DW89CNC automatic pipe bending machine | |

| Model | |

| Specification |

DW89CNCx2A-2S |

| Maximum bending pipe diameter x thickness ( steel ) | Φ89mm×6mm |

| Maximum bending radius(1) | R250mm |

| Minimum bending radius(2) | According to the pipe diameter |

| The largest bending angle | 190° |

| Maximum feeding length(3) | 3000mm |

| Feeding method | Direct feeding/Clamping feeding |

| Bending speed | Max30°/s |

| Working speed Rotary speed | Max160°/s |

| Feeding speed | Max 800mm/s |

| Bending precision | ±0.1° |

| Accuracy Rotary precision | ±0.1° |

| Feeding precision | ±0.1mm |

| Information inputting method | 1.Axis(X Y Z) 2.Working value(Y B C) |

| Bending method(4) |

hydraulic bending |

| Power of ratary servo motor(5) | 1.5KW |

| Power of feeding servo motor(6) | 2KW |

| Max ellbow bending pipe | 18 |

| Max storable sections | 200 |

| Motor power | 11kw |

| Max hydraulic pressure | 14MPa |

| Weight of machine | 5500Kg |

| Measurement size of machine | 5650×1350×1360mm |

Note: products can be provided according to customer’s requirements on tube diameter. The company reserves the final interpretation right .

Detail:

Feature:

1. Electric control system: world-renowned controllers are applied. For example, servo drivers, servo motors, positioning modules and CPU produced by Mitsubishi, Yaskawa and Delta are applied and they have strong performance and excellent stability.

2. Ultra-large CPU that can hold the edition of 400 groups of archives is applied. If it is not sufficient, transmission software can be purchased and installed for the computer. The archives can be stored in hard disk to expand the number of edit groups infinitely. (Optional)

3. WINDOWS operating system is installed in industrial computer to be mated with servo system, so it not only has the servo drive feature, but also has the archives management convenience brought by WINDOWS operating system. The archives can also be stored in hard disk or soft disk to expand the number of edit groups infinitely.

4. It can detect the error and fault automatically and display them on screen, so that the operator can eliminate the failures easily.

5. All processing data is input through the touch screen and each elbow can set compensation value, speed and demould clearance according to different materials.

6. For same tube, each elbow can have 5 action sequences and 10 sections of speed independently for operation of operators. Besides, the work efficiency can be improved and tube interference point can be reduced.

7. Chinese and English on the touch screen can be switched and the products can also be ordered according to requirements if it is another language on the screen. (Optional)

8. Materials can be delivered directly or wrapped according to requirements and XYZ coordinates can be switched to YBC processing values automatically.

9. After the completion of data editing, the data will be protected by password to prevent unapproved alteration of the data. (Optional)

10. Heat exchanger is provided for the electric control system for automatic heat dissipation. If required, NC air conditioner can be purchased to ensure service life of electric control system. (Optional)

11. The machine is provided with automatic oil injection system to reduce friction of elbow and ensure quality of elbow. (Optional)

12. The machine can be connected to a printer to print all data on the screen. (Optional)

13. Communication interface and data unit can be provided for the machine, for which the network line will be connected to Liye and engineer will conduct remote operation and control, immediate monitoring, software updating and trouble removal, etc. (Optional)

14. The feed position of feed trolley, the interference position of safety device and digital module and interference position of guide mould can be fine adjusted manually and memorized automatically to eliminate the error of manual measurement and losses caused by machine collision.

15. The feed shaft will be detected automatically before action so that it can be prevented from colliding with the machine.

16. Action segments can be selected during actual bending to observe interference points and modification work and improve efficiency.

Selection Guide:

http://www.zjgly.net/en/xxzn.html