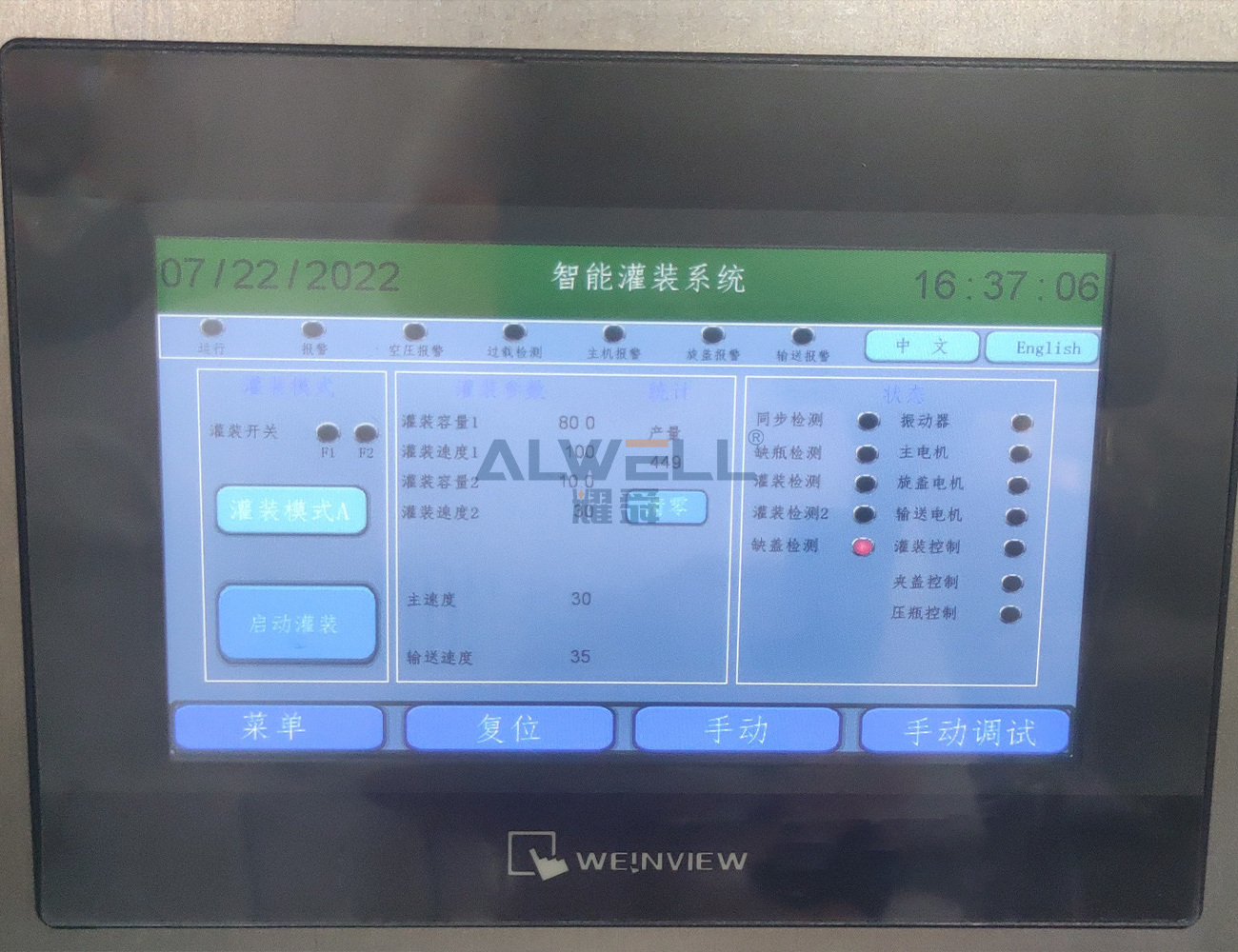

Working parameters can be set easily without the need to train operators, which helps improve work efficiency. Operation panel

language can be customized in different languages, if you need, please contact us.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 50/60hz

-

Place of Origin:

-

Shanghai, China

-

Year:

-

2021

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

2100*1500*1780mm

-

Weight (KG):

-

600

-

Core Components:

-

piston

-

Product name:

-

3-20ml reagent tube filling machine production line

-

Usage:

-

liquid filling machine

-

Function:

-

liquid filling

-

Material:

-

Stainless Steel 304 / 316L

-

Processing Types:

-

Normal Pressure Filling

-

Filling range:

-

1-100ml

-

usage:

-

disinfection liquid filling machine

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

60-70/MIN

-

Automatic Grade:

-

Fully automatic

-

Driven Type:

-

electric

-

Voltage:

-

220V/380 50/60hz

-

Place of Origin:

-

Shanghai, China

-

Year:

-

2021

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

2100*1500*1780mm

-

Weight (KG):

-

600

-

Core Components:

-

piston

-

Product name:

-

3-20ml reagent tube filling machine production line

-

Usage:

-

liquid filling machine

-

Function:

-

liquid filling

-

Material:

-

Stainless Steel 304 / 316L

-

Processing Types:

-

Normal Pressure Filling

-

Filling range:

-

1-100ml

-

usage:

-

disinfection liquid filling machine

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE ISO

Products Description

We can customize one filling line for your different bottle size.

The machine is with multiple filling nozzle which can improve filling efficiency greatly.Each filling nozzle can be controlled

separately.It is suitable for filling low viscosity liquid without particle like water,juice,milk perfume etc.This machine is

widely used in food,beverage,cosmetics and daily chemical industries.

Product Characteristics:

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5.Siemens Touch screen/PLC (optional)

6.HS Code:8422309090

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5.Siemens Touch screen/PLC (optional)

6.HS Code:8422309090

7. Accept custom MOQ: 1 PC

|

Brand

|

ALWELL

|

|

Type

|

filling machine

|

|

Number of filling heads

|

1/2

|

|

Filling range

|

1ml-50ml

|

|

Bottle diameter

|

5-100mm(Can Customize)

|

|

Bottle height

|

5-100mm

|

|

Working speed

|

0-60 bottles/min.(depending on liquid,bottle and caps)

|

|

Filling accuracy

|

1%

|

|

Qualified rate of finished products

|

Food/industry/Chemical

|

|

Applicable bottle

|

vial bottle

|

|

Warranty

|

1 Year

|

|

Material

|

Stainless Steel 304

|

|

Machine weight

|

About 341kg

|

|

Package size

|

About About 2350*1250*2100mm

|

Advantages and Details

1.

Intelligent control panel and touch screen control panel

2.Test tube vibrating conveyor

Tube feeder sorts thousands of tubes

3.Laser electronic detection

Photoelectric eye detection tube

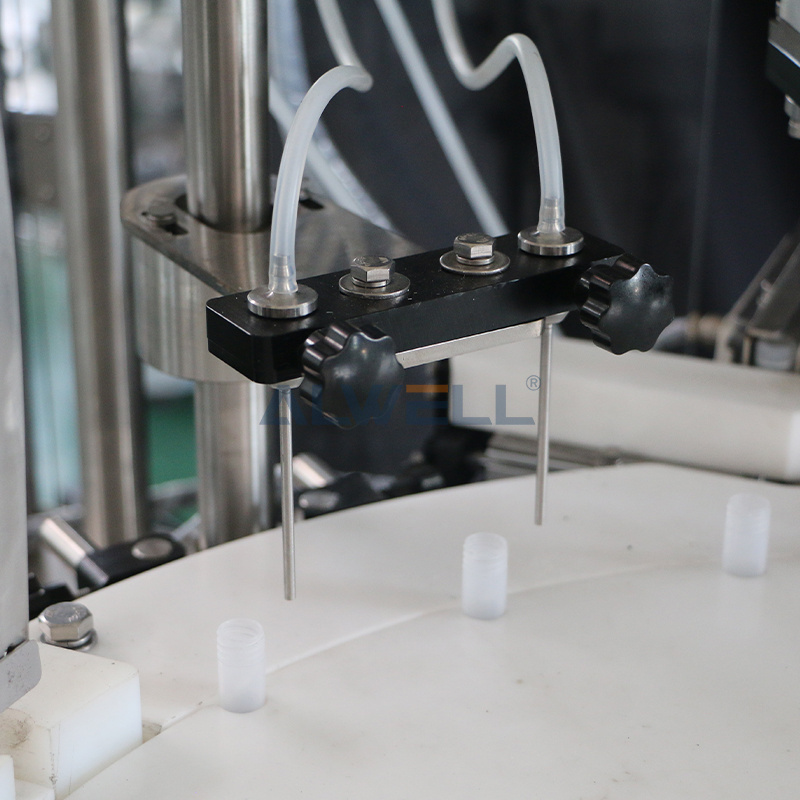

4.Anti-drip filling nozzle

Equipped with two filling nozzles,and each one can be controlled separately

The filling nozzle can be customized according to filling materials, makes the machine works better with your products This machine is equipped with high quality filling pump,ensures filling accuracy.

5. Clamp tube rotary table

The rotary dish can help to fix and transport tubes during working This dish should be customized according to tube diameter. Change different rotary dish for different kinds of tubes.

6. Tube cap vibrating conveyor

Transport the lid by vibration

7.Bottle cap conveyor

The lid automatically hangs on the tube

8.Gland device

press cap device to make sure the

lid doesn't tip over

9.Screw cover equipment

Servo motor control filling capping, finished product pass rate 99%

10.product output

Output speed can be specified

USE

This machine is mainly used for filling production line of test tubeand other small-dose products, which can realize automatic feeding,peristaltic pump filling, positioning cap, high-speed cap turning andautomatic labeling.

The machine adopts mechanical transmission to ensure accurate andstable operation, low noise, low loss, and no air pollution.The wholemachine is made of 304 stainless steel, in line with GMP requirements.

We'll change into your standard plug before shipping,such as American plug, UK plug, European plug...

* Complimentary installation kit

Product Application

Hot Searches