- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

6 T

-

Power (kW):

-

150

-

Product name:

-

Trolley furnace

-

Model:

-

DM-CBF-45

-

Chamber Size:

-

1100*550*450mm

-

Power:

-

45kw

-

Maximum Temperature:

-

1700c

-

Dimensions:

-

3040*1480*1620mm

-

Application:

-

heat treatment

-

Heating element:

-

resistance wire/ SiC rod/ MoSi2 rod

-

Temperature control:

-

PID Auto Control

Quick Details

-

Place of Origin:

-

United States

-

Brand Name:

-

Dming

-

Voltage:

-

3 phase 380v

-

Weight (T):

-

6 T

-

Power (kW):

-

150

-

Product name:

-

Trolley furnace

-

Model:

-

DM-CBF-45

-

Chamber Size:

-

1100*550*450mm

-

Power:

-

45kw

-

Maximum Temperature:

-

1700c

-

Dimensions:

-

3040*1480*1620mm

-

Application:

-

heat treatment

-

Heating element:

-

resistance wire/ SiC rod/ MoSi2 rod

-

Temperature control:

-

PID Auto Control

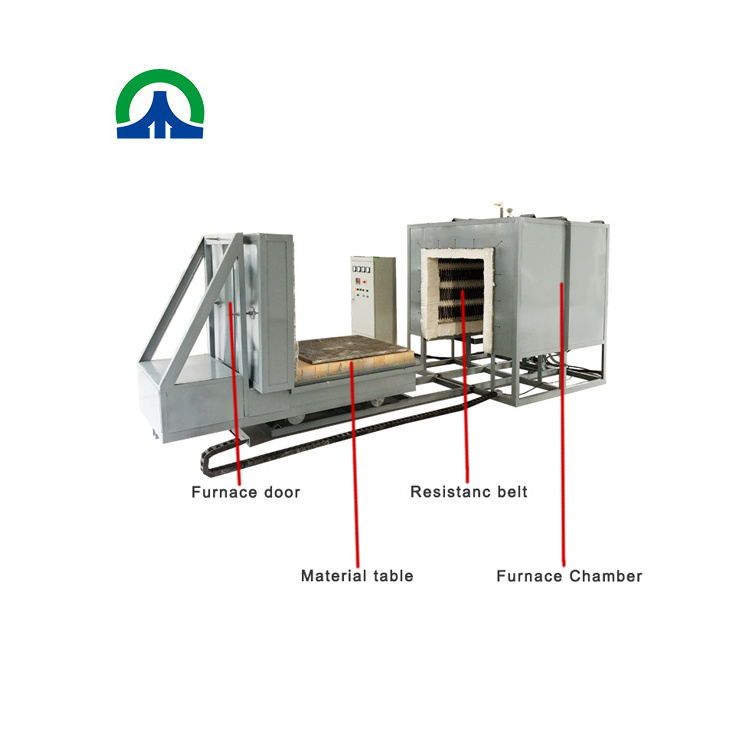

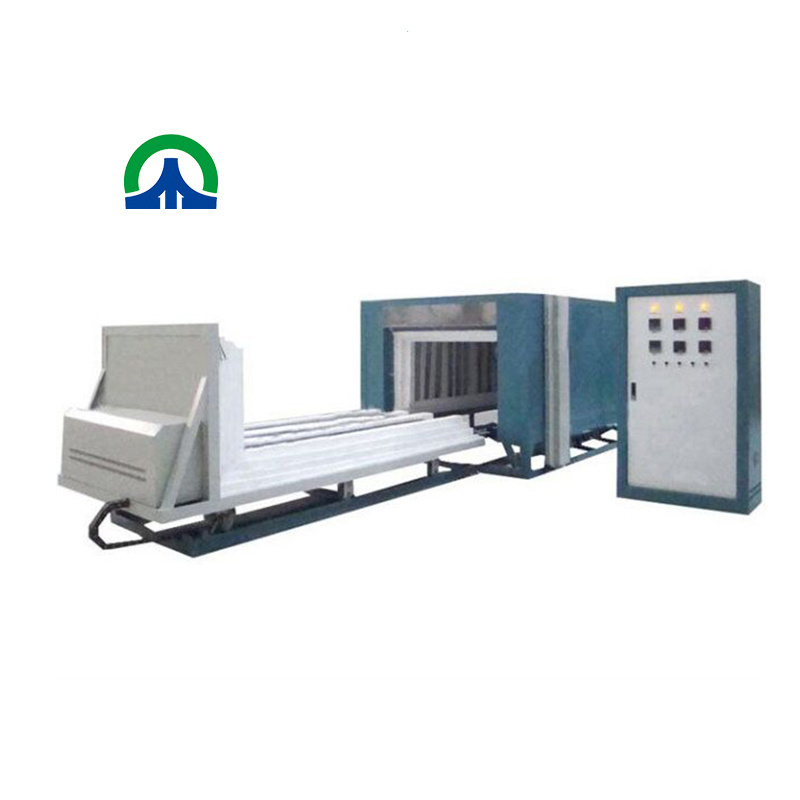

The trolley furnace is a rectangular box-shaped structure, the load-bearing platform is a movable trolley, the workpieces are stacked on the worktable, the in and out of the electric drive, the furnace door is opened and closed, and the electric control; the furnace lining is made of a full-fiber aluminum silicate throwing silk blanket made of modular building The furnace body is built with light insulation bricks and heavy refractory bricks at the bottom of the furnace. The heating system adopts resistance band heating or gas heating. The outer shell of the furnace body is made of steel plate and section steel. The furnace door and trolley adopt mechanical transmission; mainly used for Annealing, tempering, normalizing and ceramic sintering, decals and other heat treatments of various metal workpieces, such as the homogenization of aluminum rods and the aging of aluminum alloy workpieces .

|

Model |

Chamber S ize (W * H *D ) mm |

Power ( KW ) |

Dimensions (L * W * H) mm |

|

D M -CBF-45 |

1100×550×450 |

45 |

3040×1480×1620 |

|

D M -CBF-50 |

1300×650×450 |

50 |

3240×1580×1620 |

|

DM -CBF-75 |

1500×700×600 |

75 |

3440×1630×1770 |

|

DM -CBF-90 |

1500×800×600 |

90 |

3440×1730×1770 |

|

DM -CBF-105 |

1800×900×700 |

105 |

3740×1830×1870 |

|

DM -CBF-135 |

2100×1050×750 |

135 |

4060×2010×1980 |

|

DM -CBF-150 |

2300×1200×650 |

150 |

4260×2560×1880 |

|

DM -CBF-300 |

2500×1500×1500 |

300 |

4690×2860×2750 |

|

DM -CBF-65 |

1100×550×450 |

65 |

3100×1600×1750 |

|

DM -CBF-75 |

1300×650×450 |

75 |

3300×1700×1750 |

|

DM -CBF-110 |

1500×700×600 |

110 |

3500×1750×1900 |

|

DM -CBF-120 |

1500×800×600 |

120 |

3500×1850×1900 |

|

DM -CBF-150 |

1800×900×700 |

150 |

3800×1950×2000 |

|

DM -CBF-210 |

2100×1050×750 |

210 |

4120×2130×2110 |

|

DM -CBF-220 |

2300×1200×650 |

220 |

4320×2680×2010 |

|

DM -CBF-450 |

2500×1500×1500 |

450 |

4750×2980×2870 |