- Product Details

- {{item.text}}

Quick Details

-

AC voltage:

-

110/220V

-

Automatic Grade:

-

semi-automatic

-

Working medium:

-

electric, pure water

-

Warranty:

-

1 year

-

Max.gas output:

-

400L/H

-

Max.working pressure:

-

2kg/cm2

-

Product features:

-

energy saving devices,fuel saver,automatic welding

-

Wide applications:

-

air conditioning, electric motors, led lighted channel letter sign

Quick Details

-

Place of Origin:

-

Hunan, China

-

Power Consumption:

-

1.4KW/h

-

Other name:

-

oxyhydrogen welding

-

AC voltage:

-

110/220V

-

Automatic Grade:

-

semi-automatic

-

Working medium:

-

electric, pure water

-

Warranty:

-

1 year

-

Max.gas output:

-

400L/H

-

Max.working pressure:

-

2kg/cm2

-

Product features:

-

energy saving devices,fuel saver,automatic welding

-

Wide applications:

-

air conditioning, electric motors, led lighted channel letter sign

No gas cylinders safety oxy-hydrogen gas welding replace oxy acetylene welding equipment

Technical Paremeters:

| Model Number | OH200 | OH300 | OH400 |

| AC Voltage Requirement (V) | 220/110 | 220/110 | 220/110 |

| Phase | single | single | single |

| DC Voltage &Current (A) | 5V 60A | 5V 60A | 5V 60A |

| Rated Power(kw/h) | 0.75 | 1 | 1.4 |

| Max. Gas Output(L/h) | 200 | 300 | 400 |

| Max. Working Pressure (kg/cm 2 ) | 2 | 2 | 2 |

| Max. Water Consumption (L/h) | 0.11 | 0.17 | 0.23 |

| Water Feed | manual | manual | manual |

| Max. Flame Modifier Consumption (L/h) | 0.1 | 0.15 | 0.17 |

| Flame Modifier Feed | manual | manual | manual |

| Dimensions - L*W*H (mm) | 450*250*510 | 590*250*510 | 710*250*510 |

| Gross Weight (kg) | 25 | 30 | 35 |

| Ventilation Space Requirement (mm) | 200 in each direction | 200 in each direction | 200 in each direction |

HHO Oxyhydrogen technology uses water as medium to electrolyze water into H2 and O2, fire them to formed Oxyhydrogen Flame. The temperature of Oxyhydrogen flame is as high as 2800 degrees so that it can weld very fast. The quality and speed of Oxyhydrogen Flame welding method is higher than Liquid gas's.

Videos on air conditioning/led lighted channel letter sign making demonstration

Pls click or copy the link for play: http://www.okayenergy.com/video/welding-video/

Welding Industries

Oxyhydrogen flame ideal for:

1)OEM, transformers and power generators;

2)electric motor and power generator repair shop;

3)electric motor work shops;

4)large air conditioning supplies;

5)solar collectors;

6)manufacturing of large statues;

7)manufacturing of trophies, chandeliers, statues and other brass articles etc;

8)gold silver platium jewelry welding and repair;

9)musical instrument welding & repair;

10)aluminum welding for LED lighted channel letter sign making;

11)others copper welding & soldering;

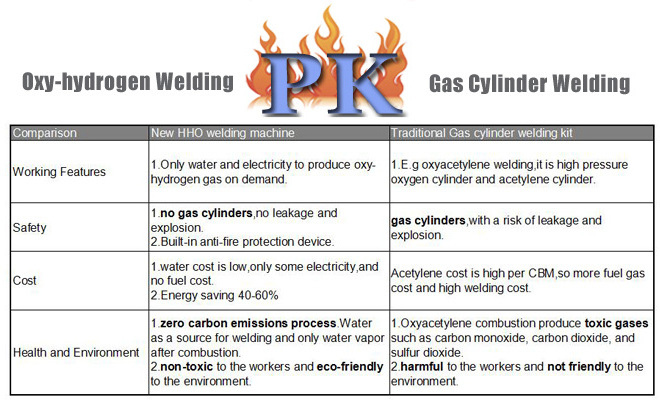

Oxyhydrogen welding features compared with oxy-acetylene welding

1. Safety

Oxy-hydrogen just uses water and electricity, no gas bottle, no hydrogen gas storage, no leakage and explosive danger.

2. Convenience

it can work just with water and electricity, every litre water can be used 7~8 hours. But Liquid gas bottle need to be changed by manual moving, it is very inconvenient.

3. Cleanliness

Oxy-hydrogen combustion just produces little water vapour, there is no harm to the pharmaceuticals. But Liquid gas combustion produces carbon dioxide, carbon monoxide and nitrogen compounds which will impact on the quality of pharmaceuticals.

4. High Efficiency

The speed of Oxy-hydrogen Flame welding method is higher than Liquid gas's.